| Machine | The main body of the machine and the parts incontact with food are all 304 stainless steel, andthe rest are made of iron, aluminum, plastic, etc |

| Manufacture Standard | CE,SGS,ISO9001 |

| Filling Material | Ground Coffee Powder, Tea Powder, ProbioticsSoluble Powder,etc. |

| Sealing Material | Sealing Foil in Roll, Precut/die-cut Foil Lids, PaperFilm, etc, |

| Production Capacity | 200-240capsules/min. |

| Filling Method | Servo Motor Driving the Auger Screw, much moreprecise |

| Filling Weight | 5-5.5g |

| Feeding Method | Vacuum Feeder + Horizontal Screw |

| Filling Accuracy | ±5% (AVG. W.t. of 10,000 data) |

| Power Supply | 3Phase 380V 50/60HZ 16KW |

| Compressed air pressure (bar) | 0.6Mpa-0.8Mpa |

| Compressed Air Consumption | 0.9 m*3 / minute |

| Nitrogen consumption(Nm3/h) | 65-80 |

| Machine Weight | 3500Kg |

| Machine Dimension | 5300mm (L)*1760mm(W)*3230mm(H)(Based on the real size) |

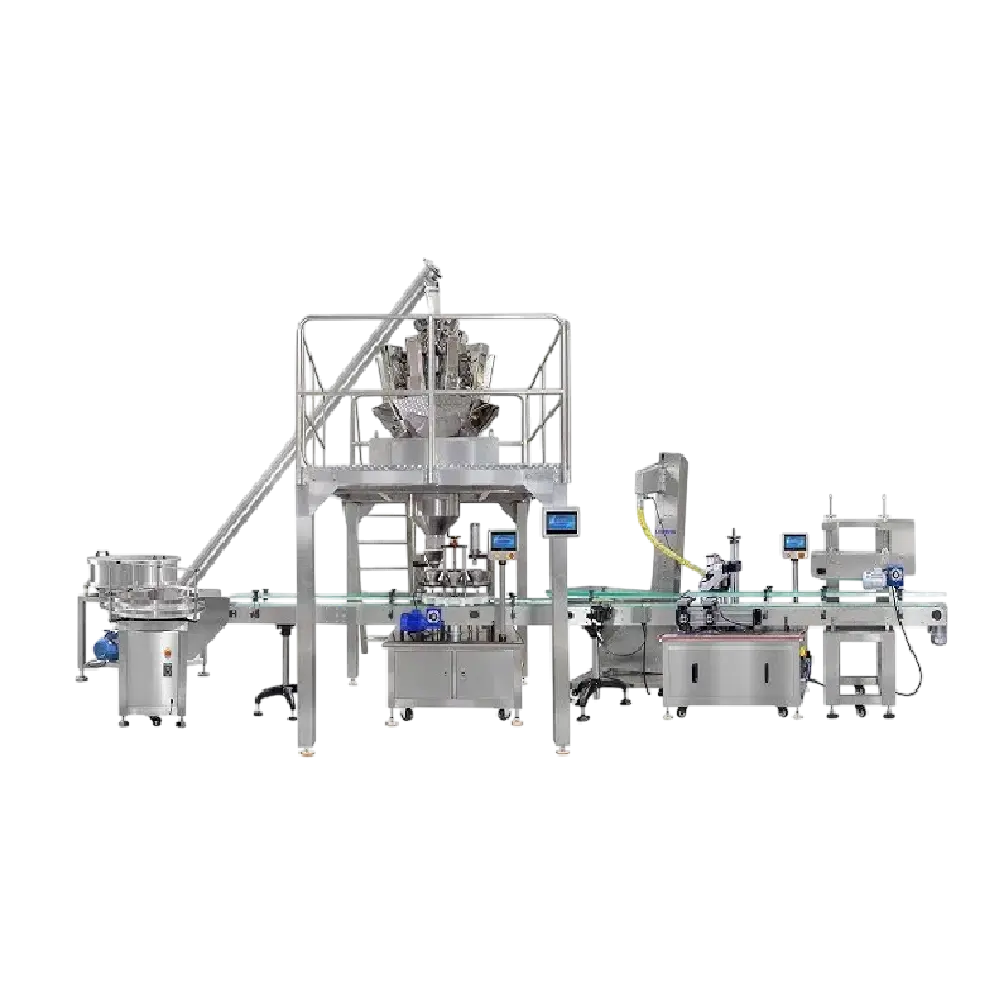

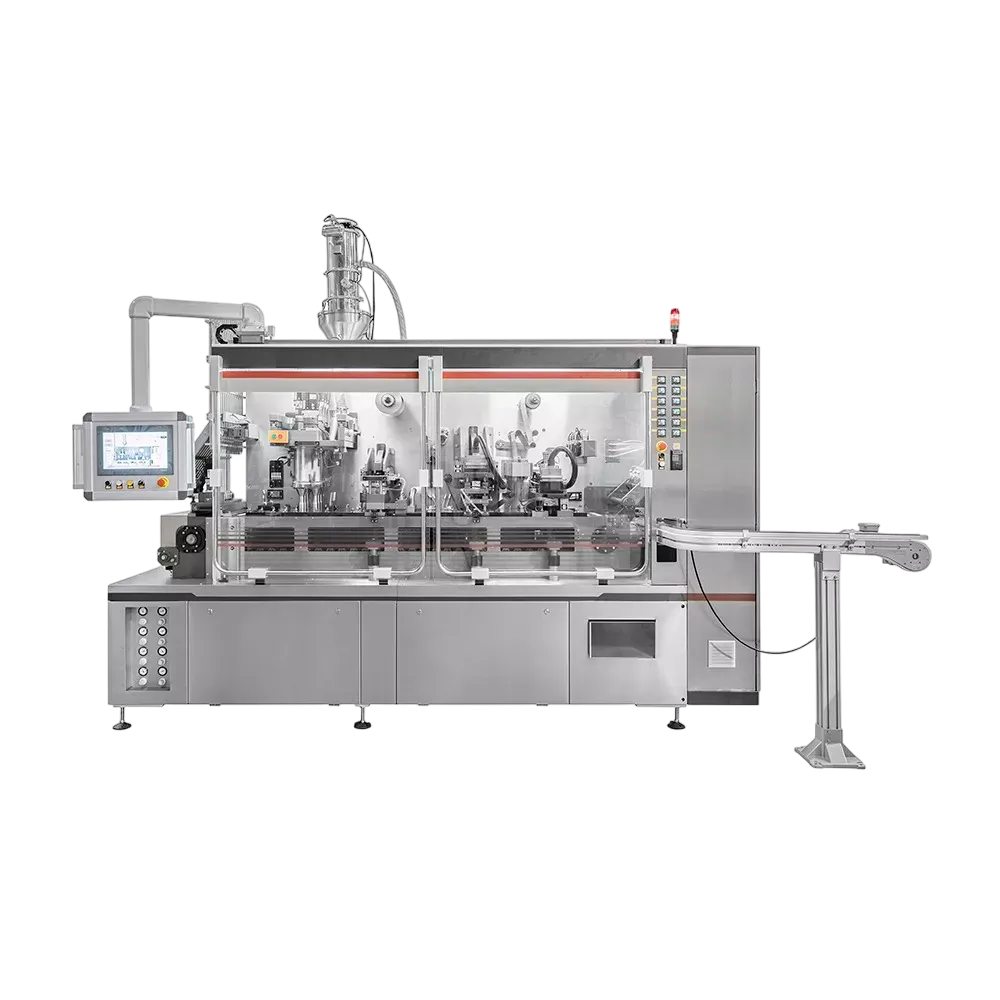

DTC-4 Coffee Capsule Filling and Sealing Machine

These days, everyone wants their coffee quick, so how coffee gets made, put into packages, then enjoyed has really changed. Coffee pods are now super popular – people who truly love coffee alongside those making it appreciate having a simple, reliable, fresh brew. Coffee needs keep climbing, so the DTC-4 machine was built to quickly fill then seal many kinds of coffee pods – Nespresso, Dolce Gusto, Lavazza, K-Cup, even Tchibo. It’s an efficient, accurate tool any contemporary coffee packager would benefit from.

Introduction to Coffee Capsule Machine

Modern machines expertly fill coffee capsules then package them. These systems use clever design alongside automated processes. Getting the right amount of coffee into each capsule keeps its flavor strong, extends how long it stays good, and ensures a tight seal. The goal? Swift, clean work – no mess, always the same. That’s what the DTC-4 does. It churns out capsules rapidly, yet reliably seals each one flawlessly, batch after batch.

For coffee makers wanting both speed alongside top-notch results, the DTC-4 packs inventive tech, dependable build, also consistent performance into one small machine. It handles capsule filling likewise sealing – no compromises needed.

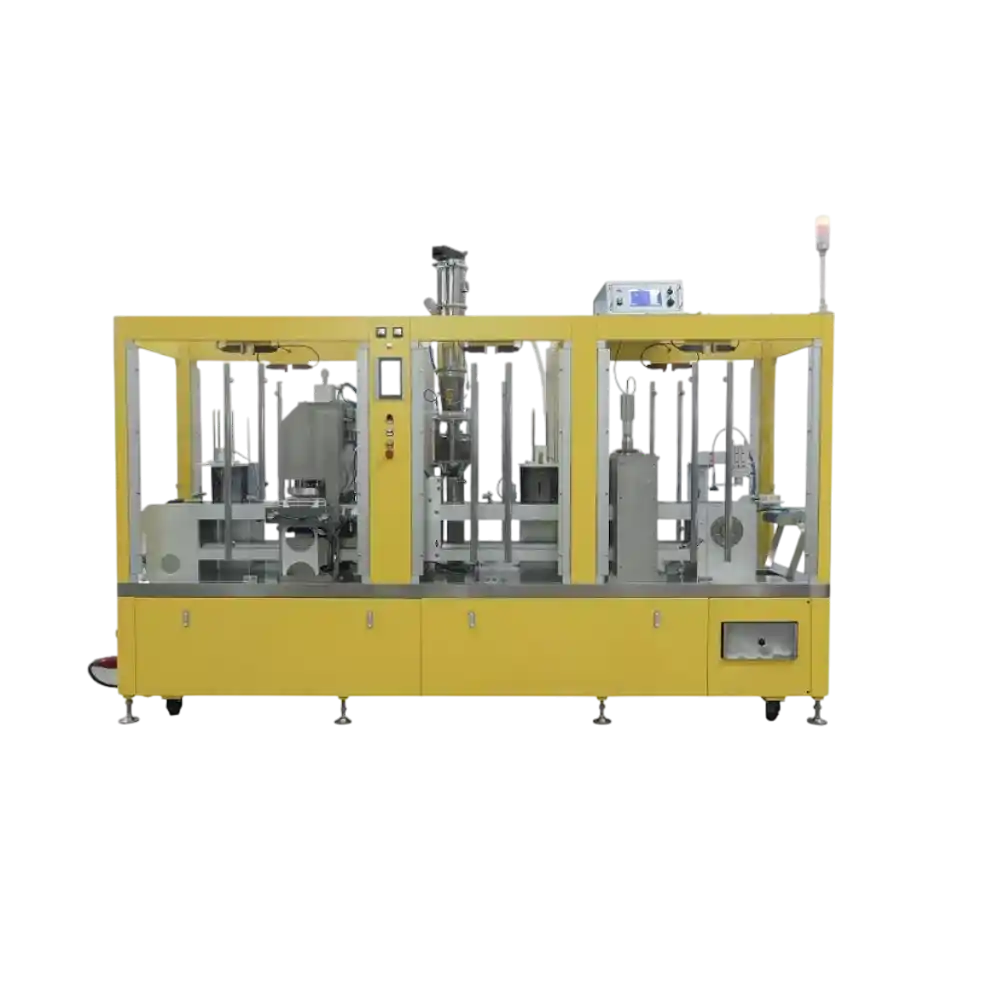

Multi-type Capsule Production

The DTC-4 Coffee Capsule Filler handles many kinds of pods. It works with Nespresso, Dolce Gusto, Lavazza, K-Cup, even Tchibo capsules. So, businesses can make different varieties using just one machine – a real boost for getting things done.

Switching between capsule styles happens quickly, without fuss. Staff readily swap out supplies alongside the forms. Consequently, things move faster – meaning more capsules get made.

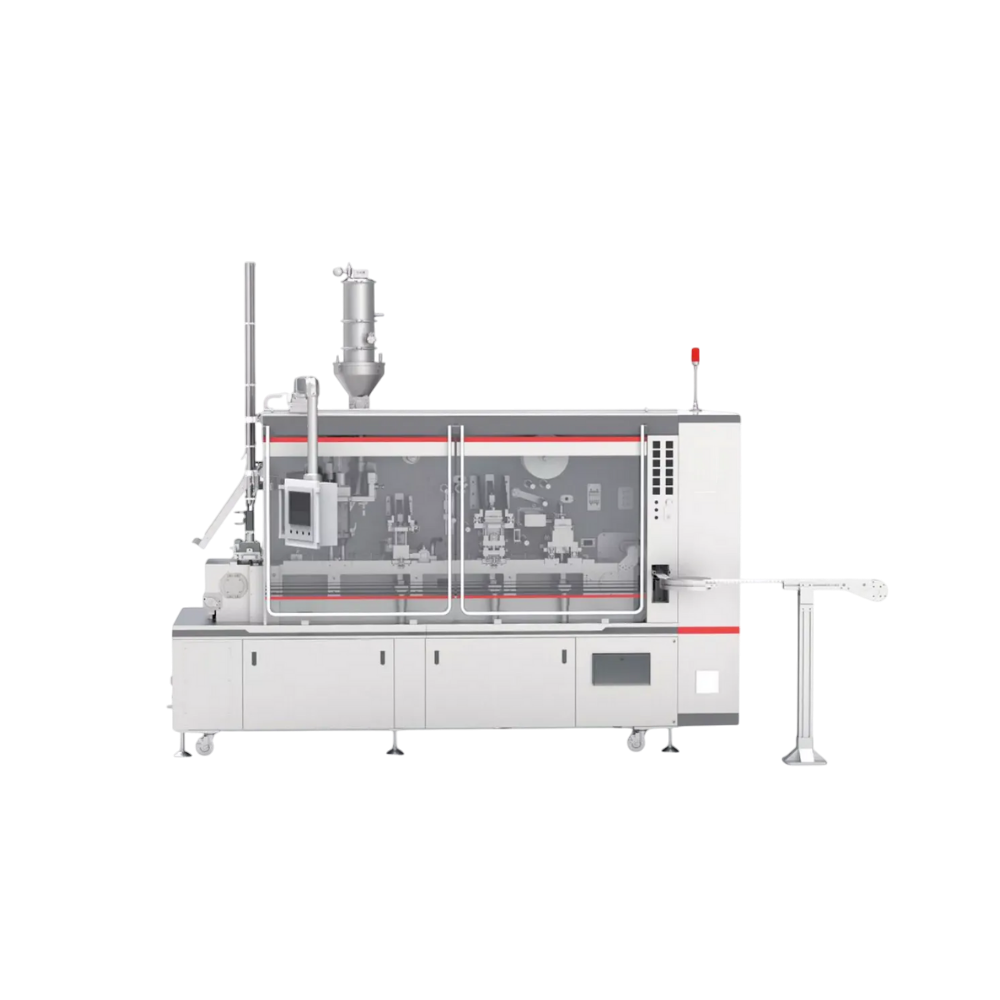

Four-Filling High-Efficiency Design

This machine, the DTC-4, handles filling then sealing four containers at once. Consequently, output jumps considerably. Everything works together seamlessly – a coordinated process yielding consistent quality.

The DTC-4 quickly makes lots of coffee, so it suits bigger businesses that value consistent quality alongside fast output – it’s built to last too.

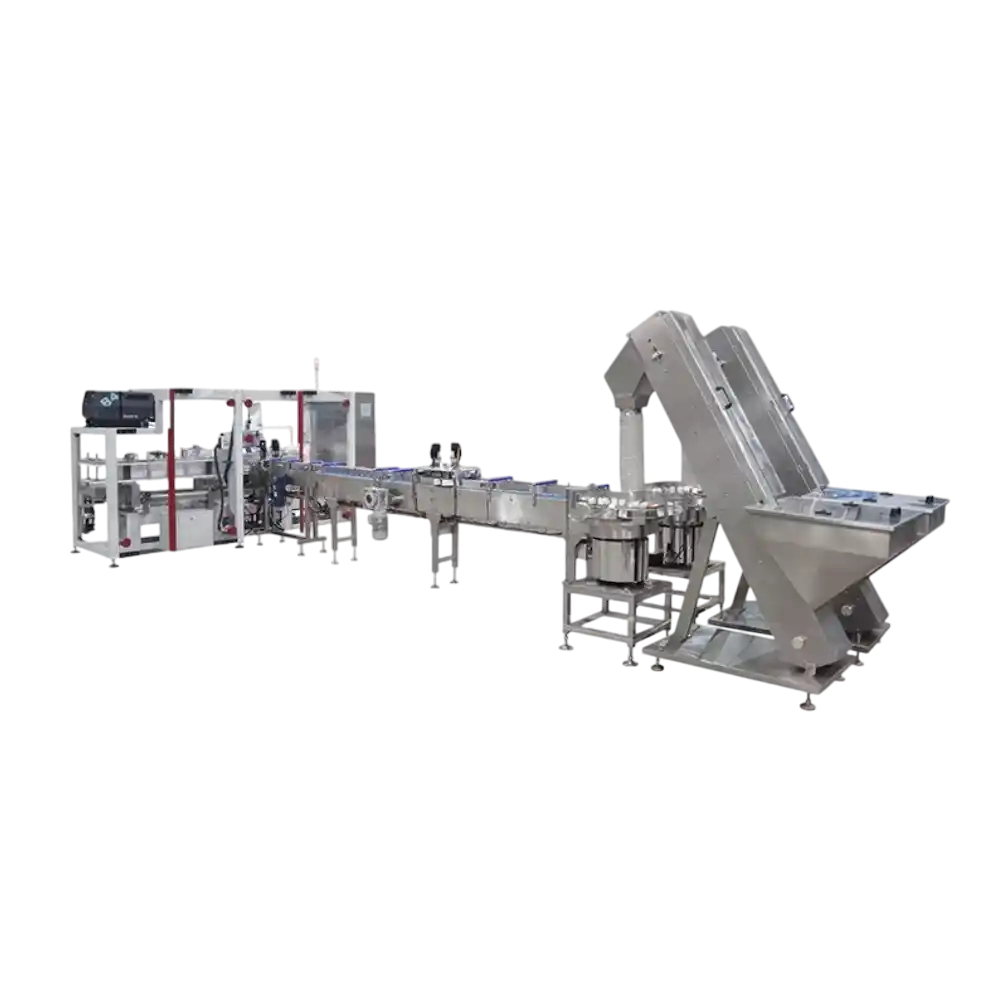

Production Process Overview

Here’s how the DTC-4 works – it takes blank capsules, then fills and seals them, ultimately boxing up the finished product

- An automated setup delivers blank capsules to the equipment.

- Each capsule drops – one by one – into its mold, delivered directly from the feeder.

- Each coffee pod gets a measured dose of grounds – a little machine with serious accuracy handles that, ensuring every one is just right.

- The coffee within each pod gets packed down – just enough for a perfect brew. This ensures different coffees steep at the right speed.

- Capsules receive pre-made foil covers. It’s a simple placement – foils go on capsules.

- The device closes capsules – sometimes with sound waves, at others via warmth – based on what the foil is made of.

- Capsules, once made, get put into packaging according to specifications.

Keeping this system running smoothly means things get done quickly, with little waste.

Filling System

Getting the right amount of coffee into each capsule matters – even tiny differences change how it tastes, smells, or brews. This machine uses a carefully controlled screw-feed system for consistent measurements. Operators can tweak settings like fill weight, pace, and how tightly packed the grounds are, depending on both the bean variety and capsule dimensions.

Beyond accuracy, this machine keeps dust down while cutting coffee loss. Food-safe stainless steel builds – either a specific grade or another if needed – guarantees cleanliness alongside lasting performance. It handles tea, chocolate, instant coffee, or similar dry goods too.

Sealing Technology

Airtight capsules depend on how well the sealing works – it’s key. This machine, the DTC-4, keeps things sealed tight by carefully controlling heat at that stage, all managed through a simple touchscreen. You tweak things like heat, how long it seals, likewise pressure right on the machine’s display. Whether to use sound waves or warmth for a good seal depends on what kind of capsules and foil you have.

The DTC-4 handles many kinds of capsules – aluminum, plastic, even plant-based ones. It seals them tightly, so coffee stays flavorful longer.

Automation and Control System

Operators use the DTC-4’s touchscreen – it links a PLC to an HMI. Consequently, they can readily track how things are going, seeing totals made, weights achieved, also any flawed items.

A PLC manages how filling, capping, then packaging happen together without a hitch. Furthermore, it keeps tabs on everything – production levels, shift results, plus offers insights through recorded data.

Keeping people safe matters most. This machine – the DTC-4 – has sensors, quick-stop buttons, also safeguards to halt work if access panels aren’t secured. It’s built following European safety rules alongside global guidelines for machines making food packaging.

Construction and Materials

Built using top-notch stainless steel, this coffee capsule machine stays clean, resists rust, then lasts through tough daily use. It’s designed to be small yet solid – meaning steady operation alongside quiet performance.

Components touching your product use safe materials; smooth surfaces make cleanup a breeze. Because it comes apart easily, this equipment simplifies upkeep – a fast wash between batches keeps things running smoothly.

Production Capacity

The DTC-4 cranks out a lot of capsules – as many as 12,000 an hour depending on what you’re making – thanks to its four processing lanes, yet still keeps things reliable. A smart motion system coordinates everything so it runs steadily even during extended use.

The machine isn’t just fast; it’s built to cut down on scrap while getting the most from materials. A careful way of adding ingredients, solid seals, alongside a streamlined process means less wasted stuff – materials or power – so making things is kinder to the planet.

Adaptability for Multiple Capsule Types

Coffee making changes fast. The DTC-4 shifts gears easily, handling various capsule types – whether they’re made of plastic or another material. It works with Nespresso, Dolce Gusto, Lavazza, K-Cup, even Tchibo capsules; swapping out parts lets it adjust without delay.

Because it’s so versatile, a coffee maker lets farmers offer more products – reach diverse customers – with just one machine. Likewise, smaller businesses can build up operations without needing to buy lots of new gear.

Maintenance and Cleaning

The DTC-4 is built for straightforward upkeep. Replacing components – like fillers, seals, or molds – is fast because they detach readily. Moreover, automated air blasts clear away coffee grounds alongside dust, ensuring a clean operation.

You can get optional automatic cleaning features, making washdowns super effective – particularly if you run a lot of batches. Routine checkups keep the machinery running smoothly while also safeguarding how good your products are.

This coffee capsule maker excels because of careful engineering alongside smart controls. It’s built to minimize wasted motion, materials, then power. The rotary table moves with incredible accuracy thanks to servo motors, positioning each capsule – no matter its size or maker – perfectly for filling. Consequently, the dispensing nozzle delivers a consistent amount of ground coffee into every one, even while producing thousands hourly.

Dosing System

The DTC-4 fills containers using measured amounts, alongside a feeder that uses suction. This setup curbs dust so your work area remains tidy; moreover, you won’t waste any material. It doesn’t merely look good – the vacuum packs coffee grounds uniformly into capsules, delivering consistent density and flavor with each brew. Need to adjust how much goes in? A quick tap or two on the screen handles it. You can readily adjust recipes, or even try a new coffee – from powdery espresso to coarser filter types. The DTC-4 adjusts instantly; there’s no requirement to change components or fiddle with its mechanics.

Multi-Compatibility and Flexibility

This machine? It’s remarkably versatile. Basically, it works with nearly every pod type imaginable – Nespresso, Dolce Gusto, Lavazza, K-Cups, even Tchibo. Swapping the tool kit lets you use them all. Consequently, operations run smoother – you adapt products easily, sidestepping the need for a machine per brand. Manufacturers handling varied client needs discover the DTC-4 becomes an all-in-one answer.

Capsules aren’t one-size-fits-all; each presents unique challenges regarding shape likewise how they must be sealed. Luckily, the DTC-4 adapts – it handles everything. Consider Nespresso pods, requiring a cool, airtight closure. However, K-Cups…? A tighter seal on the flange is what they need. The DTC-4 detects any variation – then adjusts heat alongside force, ensuring each capsule closes just right, irrespective of its design.

Robust Structural Design

Crafted entirely from robust 304 stainless steel, the DTC-4 withstands wear, sidesteps rust, moreover meets global standards for safe food handling. Its surfaces – polished to a gleam – ensure quick cleanup alongside superior hygiene. Components meeting coffee get crafted from safe materials – they simply detach for thorough washing. Its build allows quick fixes, so upkeep doesn’t interrupt work, assisting compliance with demanding cleanliness rules, notably when shipping internationally.

Keeping people safe is built right in. Clear panels allow viewing during operation, while intelligent safeguards halt everything immediately should a panel be opened. Consequently, mishaps are reduced – you remain compliant with current safety standards.

Automation and Control System

A central, intelligent controller manages everything via a vibrant touchscreen. It displays real-time data while letting operators adjust filling amounts, seal temperatures, alongside machine pace – directly on the display. Because it supports numerous languages yet adapts to varying expertise, both experienced staff but also newcomers operate the equipment easily.

The machine swiftly delivers capsules, then lets them go. It neatly arranges them – no snags ever! After filling and sealing, completed capsules travel along a belt toward their next destination. Keep tabs on what you make – bolt on tools to count items or measure their weight, then link that info directly to how much stuff gets done.

Precision Sealing Technology

The DTC-4 seals capsules using either heat or sound waves, whichever works best. It heats aluminum capsules like those from Nespresso to fuse the lid tightly shut. Instead, plastic or plant-based capsules get a sonic seal that preserves freshness alongside their scent.

The sealer’s temperature stays remarkably steady – never more than one degree off target. Consequently, each seal forms perfectly, avoiding burns or weak spots. These containers are designed to remain sealed, keeping contents unspoiled whether on the move or sitting still. Clever control over timing and force prevents crushing – or spills – even as things speed up during manufacture.

Nitrogen Flushing System

Good coffee needs to be fresh. That’s why the DTC-4 pushes out oxygen from each capsule with nitrogen prior to sealing – preserving the flavor instead of letting it fade. Nitrogen levels are customizable to meet your needs, while smart gas use minimizes wasted product. Consequently, sealed capsules maintain their scent also taste over many months following packaging.

Productivity and Output

The DTC-4 really delivers on production. It simultaneously runs four lines, potentially yielding as many as 12,000 capsules per hour; however, this figure shifts based on capsule type or fill volume. Changing the pace is straightforward. It’s straightforward – speed doesn’t mean compromising results. This equipment handles everything from medium businesses to large plants; moreover, it works well for co-packers managing multiple labels.

The DTC-4 adapts with you. It begins simply, yet expands as required – perhaps needing label application, security closures, or edge polishing. Rather than replace everything later, merely connect what’s next as output increases.

Ease of Operation and Maintenance

The DTC-4 feels built for real life. Changing pieces is fast thanks to quick releases, also everything’s labeled plainly – no more frustrating repairs. It even monitors its own condition. The system keeps tabs on its parts – sensors, motors, airflow – using built-in checks. Should anything go awry, whether a misaligned component or insufficient air, a notification appears on the touchscreen. Operation halts there, awaiting repair, so fewer items get scrapped.

Keeping things tidy couldn’t be simpler. Stainless steel alongside parts that come right off means quick cleanup – more time working, less scrubbing. Moreover, because the powder stays contained, there’s no coffee haze or mess, regardless how busy it gets.

Environmental and Energy Efficiency

The DTC-4 doesn’t merely deliver results; it considers our planet. Its motors sip power compared to older air-powered systems. To minimize scrap, nitrogen combined with warmth does the trick. Should you opt for greener packaging, this machine effortlessly processes both biodegradable likewise compostable capsules – seals remain tight.

This device cuts energy use, minimizes waste, integrates well with eco-friendly practices – a real fit for manufacturers aiming to be more responsible. Consequently, it’s a forward-thinking choice for businesses.

Integration into Coffee Production Lines

Getting the DTC-4 working with your coffee setup couldn’t be simpler. It connects directly to grinders, dosers, also packaging machines, creating one smooth, automatic process – from whole bean to sealed capsule. Want to grow? The DTC-4 integrates well into bigger setups; monitor capsule counts, coffee levels, or batch info effortlessly.

It meshes well with the tech you already use. Because it operates on accessible standards, linking it to manufacturing execution or enterprise resource planning software is simple, letting you oversee production schedules, upkeep, alongside quality control directly from a desktop.

Quality Control and Accuracy

Making coffee pods demands precision – the DTC-4 delivers. It consistently fills each capsule to within a tenth of a gram, thanks to its internal checks and adjustments. Moreover, because the machine operates with four separate filling lines, issues on one line won’t disrupt production across the others.

Need a tighter grip on standards? You could tack on visual checks. The system inspects caps, seals, then markings; therefore, only top-quality capsules proceed to be packaged – eliminating repetitive hand inspections. Moreover, every bit of production info gets recorded, ensuring full traceability alongside adherence to food safety rules.

Applications in Coffee Capsule Manufacturing

The DTC-4 shows up wherever coffee gets made, whether at a tiny shop valuing control or a huge plant operating constantly. Mid-sized companies appreciate how little space it occupies alongside its performance. Larger businesses depend on its consistent operation while also being able to expand quickly.

Those who make goods for other brands really benefit. Changing what they produce – from Nespresso pods to K-Cups, for instance – happens fast; just switch the mold, adjust the screen, and begin. This adaptability means keeping pace with customer preferences, debuting unique flavors, or expanding product offerings doesn’t require huge expenses.

This machine doesn’t limit itself to espresso; instead, it handles practically anything powdered – from quick coffees alongside cocoa, even things like milk powders, vitamins, or collagen. The sealed design maintains ingredient integrity; tweak formulas fearlessly, knowing flavors won’t mix. Consequently, this allows expansion into areas such as health boosters or vitality supplements – all crafted on existing equipment.

Engineering Excellence and Reliability

The DTC-4 is built to run constantly in factories. It uses accurate parts – bearings, a steel frame, controlled motors – for lasting reliability. Because it moves smoothly with little shaking, things don’t wear out quickly, also keeping sounds under 75 dB, which helps create a better workspace.

The four manufacturing lines work together seamlessly; if one line speeds up or slows down, the system adjusts automatically. Because of this clever coordination, every capsule travels consistently through production – so each one gets filled equally well, with a strong, reliable seal, whether it’s made early or late in the run.

Digital sensors keep tabs on temperature, pressure, likewise fill weight. A PLC gathers this information, storing it so personnel can check how things are running, spot patterns, then schedule upkeep before issues arise. Because of this, the DTC-4 runs remarkably well – typically staying online more than 98% of the time in factories.

Modular Design for Custom Configurations

Because the DTC-4 is built from separate parts, factories can customize each assembly line to fit what they truly require. It starts with filling, sealing, then removing capsules – however, more complex setups also feature capsule washing, nitrogen purging, label application for lids, alongside automated boxing.

A coffee capsule business aiming for top quality might choose equipment that seals tightly while keeping air out. However, a firm filling single-serve cups could instead want bigger bins, a longer moving belt, then boxes filled automatically.

Manufacturers can grow investments bit by bit – begin with a modest setup, then expand alongside demand. A uniform structure means fresh components fit right into what they have, so no major overhauls are necessary.

User Experience and Operator Training

Comfort and security guided how we built the DTC-4. Its touch screen shows everything you need to know – easy symbols, straightforward controls. The machine lets people save different sets of instructions – how much material goes in, how long to seal it, what temperature to use – for various capsules. Changing these settings is swift, meaning less time spent getting ready.

Learning the ropes isn’t hard for newcomers. Typically, people get comfortable with the essentials after just a bit of practice – a handful of hours, generally. The interface walks people through starting up, tuning, then powering down. Moreover, alerts for safety issues – as well as when upkeep is needed – pop up on the display, so mistakes happen less often.

You can keep tabs on the machine from a distance using add-on network tools. Managers observe how things are running – numbers made, alerts triggered – using their own equipment; this helps them stay informed while maintaining steady results across different work teams.

Hygienic Design and Food Safety Compliance

Making safe coffee capsules matters a lot. The DTC-4 helps with this because its build keeps things clean – every surface touching the coffee follows global rules for food machines. It has seamless connections, closes tight where needed, also comes apart easily so nothing sticks around to cause germs.

Dust doesn’t stand a chance near where things get filled because of how the air moves – clean air circulates thanks to special filters. When it’s time for upkeep or a scrub down, essential parts come apart easily, needing zero tools, so everything is spotless quickly. Because we only utilize materials cleared by health officials, passing inspections like those for HACCP or ISO 22000 isn’t an issue.

To keep things pure, a nitrogen flush pushes out oxygen and dampness while the capsules are sealed. Consequently, each one delivers the same great flavor, scent, and quality – from when it’s made until you brew it.

Benefits for Coffee Producers

Coffee makers wanting dependable operation, adaptable performance, moreover streamlined workflows will discover real benefits from the DTC-4

- The machine cranks out a hefty stream of capsules – as many as 12,000 every sixty minutes – thanks to its four working parts moving together seamlessly.

- It works with capsules from Nespresso, also Dolce Gusto, Lavazza – even K-Cups or Tchibo systems.

- Switching tasks is swift – tools swap out fast, alongside saved settings, so production barely pauses.

- Filling is precise – within 0.1 grams – because the system self-corrects.

- To keep things good longer, we fill packaging with nitrogen – this helps food stay fresh while locking in its smell.

- Built from stainless steel, it conforms to global food safety rules.

- Keep expenses down: Motors sip power, also we scrap less stuff.

- Built to last, this uses tough parts so you won’t be fixing things constantly.

- The system grows easily – its build lets us add to it as demand increases.

- The system keeps a detailed record of how things are made, helping to ensure everything meets standards.

Manufacturers gain a real boost from these benefits – a crucial advantage when rivals are many, steady quality matters to customers, likewise keeping expenses down protects earnings.

Innovation in Coffee Capsule Technology

Folks increasingly want great coffee, simply made. Devices such as the DTC-4 help fulfill this need – they allow companies to produce lots of capsules so people can enjoy exceptional coffee without leaving their kitchens.

The DTC-4 stays current as capsules shift to plant-based plastics alongside aluminum replacements. Because of its adaptable sealing, manufacturers can test sustainable options – like PLA or PHA – while maintaining both a solid closure and fast production rates.

Coffee capsules are getting better, so companies work harder to keep flavors fresh. The DTC-4 uses nitrogen alongside tight seals; therefore, coffee stays flavorful – crema included – for longer, which appeals to people who really know their coffee.

How the DTC-4 Stacks Up

Switching from older, basic fillers to the DTC-4 is a noticeable improvement. Those simpler models have a low price tag, yet struggle to maintain speed or evenness. Okay for small jobs, however they falter when output needs to grow. Unlike others, the DTC-4 squeezes serious strength into a small build. Quick, accurate – it barely takes up any space.

Now it just goes – all by itself. Forget constantly checking up on things, likewise fretting over human error. With labor expenses declining, product quality improves. This new servo control system ensures operations flow seamlessly while extending component lifespan – a substantial improvement compared to previous pneumatic setups.

Forget those enormous, multi-lane filling systems. This DTC-4 hits a nice balance. Those larger setups churn through tons of product, yet often demand single capsule types alongside ongoing repairs. Instead, the DTC-4’s four lanes accommodate various capsules without relentless upkeep.

Options and Upgrades

The DTC-4 does more than one thing. Depending on your requirements, several improvements are available

- The machine stays stocked with capsules – whatever kind you need – doing the work for you.

- A printer – or maybe a laser coder – stamps lids directly with things like dates, batch codes, or your logo.

- This system checks products – it finds faulty seals, off-center caps, or incorrect amounts inside – before problems become apparent.

- The machine gently places completed capsules directly into shipping cartons, streamlining the process.

- The vacuum loading system automatically transports coffee grounds from storage to the hoppers.

- This dehumidifier tackles dampness – vital when mixing ingredients that don’t play well with water.

The DTC-4, equipped with these extras, becomes a self-sufficient workshop – it operates continuously needing little oversight.

Maintenance and Service

The DTC-4 is straightforward to maintain. Large doors open things up, so there’s no need for tools to reach components – everything vital sits at the forefront. Grease fittings cluster together; moreover, the machine’s internal computer flags servicing intervals according to runtime.

Keeping things running smoothly involves occasional checks of vacuum levels, gas quality, alongside sensor adjustments. Replacing wear parts like seals, blades, or filters takes moments without halting work. Because this equipment proves dependable, unexpected stops are rare – a real benefit during busy periods.

Energy Efficiency and Sustainability

DTC-4s begin conserving energy immediately. Motors work alongside intelligent power controls, ensuring the device consumes only necessary electricity. If a lane is unused, it automatically conserves power. Moreover, the heat recovery system reclaims wasted energy, giving it another life.

We’ve also sorted out nitrogen – it’s under control. Gas flows are tracked precisely, meaning nothing goes to waste.