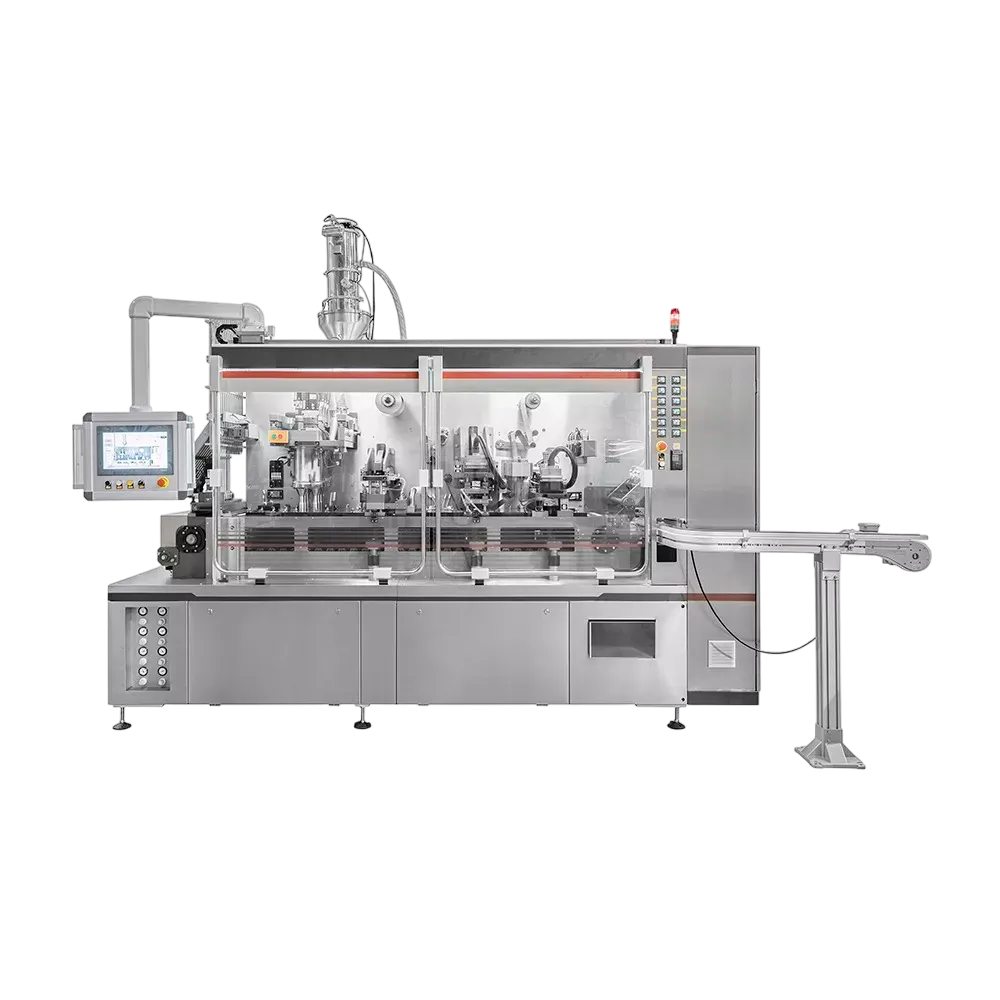

| Machine | The main body of the machine and the parts incontact with food are all 304 stainless steel, andthe rest are made of iron, aluminum, plastic, etc |

| Manufacture Standard | CE,SGS,ISO9001 |

| Filling Material | Ground Coffee Powder, Tea Powder, ProbioticsSoluble Powder,etc. |

| Package Type | Drip PAckafe, Ufo Drip Filter Coffee Package |

| Production Capacity | Depends on requirement |

UFO Drip Coffee Filling and Packaging Machine: Revolutionizing Coffee Packaging

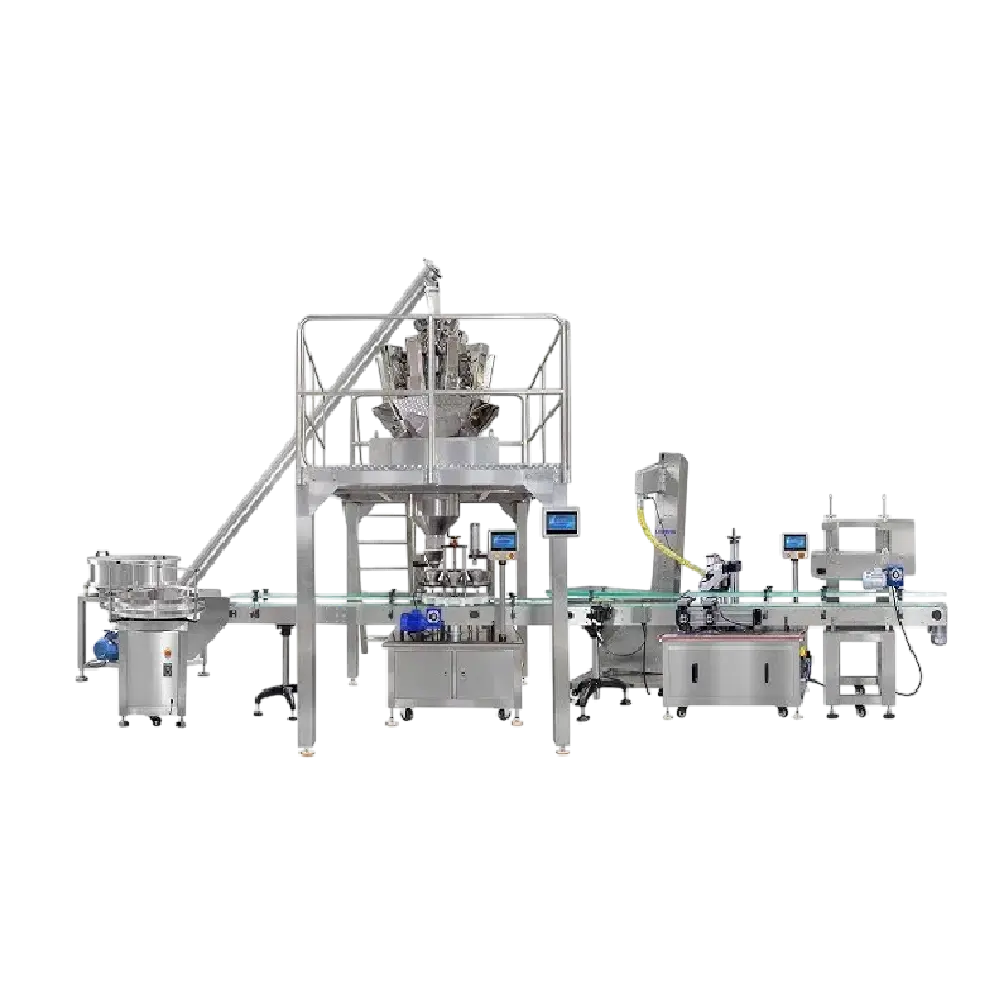

Coffee businesses face constant pressure to keep up with what people want. The UFO Drip Coffee Filling and Packaging Machine helps them do just that – it quickly, accurately fills then seals coffee containers. It’s built for both little shops alongside bigger companies; the DTD version aims to boost how much coffee gets packaged without sacrificing taste or evenness.

Overview of the UFO Drip Coffee Filling and Packaging Machine

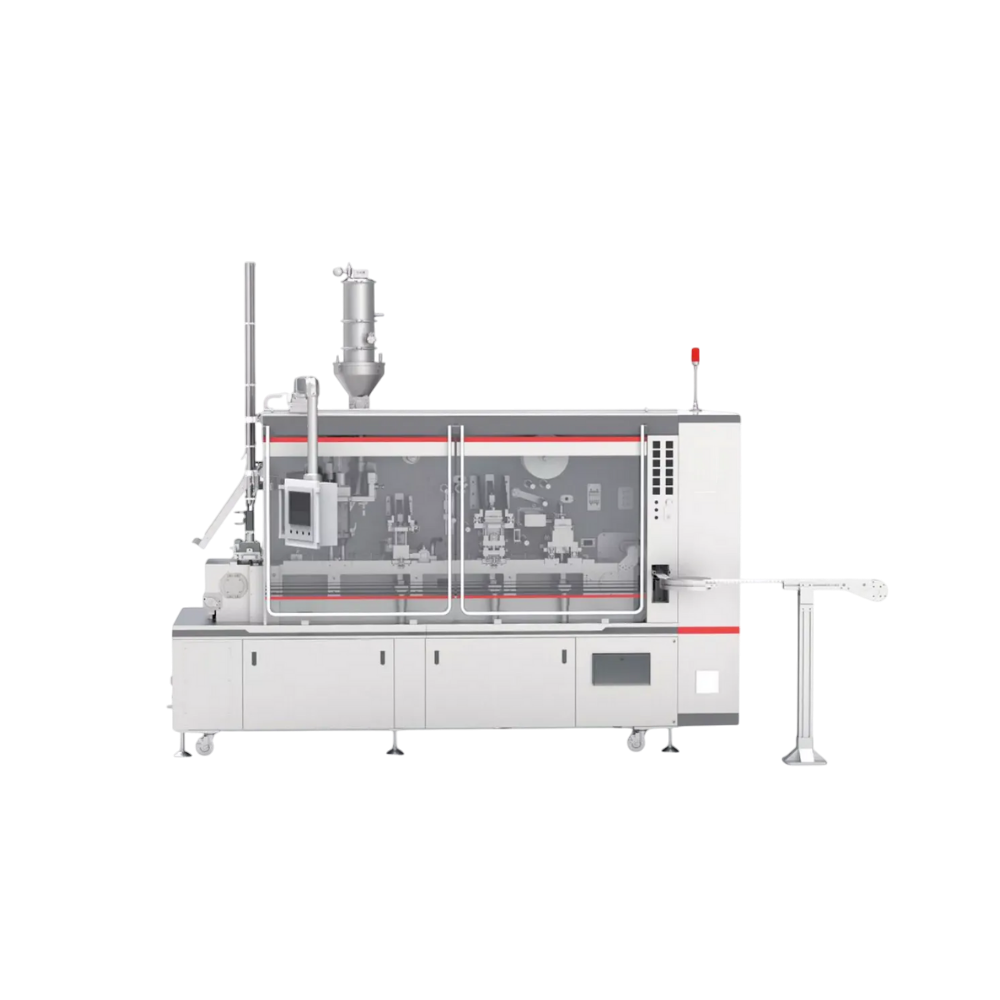

A clever device – the UFO Drip Coffee Filling and Packaging Machine – automatically packs drip coffee filters. It swiftly puts coffee into bags, closes them securely, then readies everything for shipping while maintaining strict cleanliness. Businesses wanting quicker packing or new products will find this particularly useful.

The UFO Drip Coffee Machine streamlines packing – it’s fast, simple to use, cuts down on mess, then delivers uniform packages. Consequently, coffee businesses can boost output alongside staying ahead of rivals.

Key Features of the UFO Drip Coffee Filling and Packaging Machine

- Automatic Operation

- This coffee machine handles everything – from filling packets to sealing them – without much help from people, so mistakes happen less often. Because of this, companies can produce more coffee, faster. It helps them keep up when lots of customers want it.

- Precise Coffee Filling

- This device uses clever tech to put just the right amount of coffee in every bag. Because of this accuracy, each package delivers similar flavor and scent – what people anticipate from their brew.

- Sealing and Closure

- Once filled, this coffee machine quickly closes each bag – no spills, no worries about freshness. It packs everything tight so the coffee stays good, while also helping avoid messed-up packaging and maintaining a clean look.

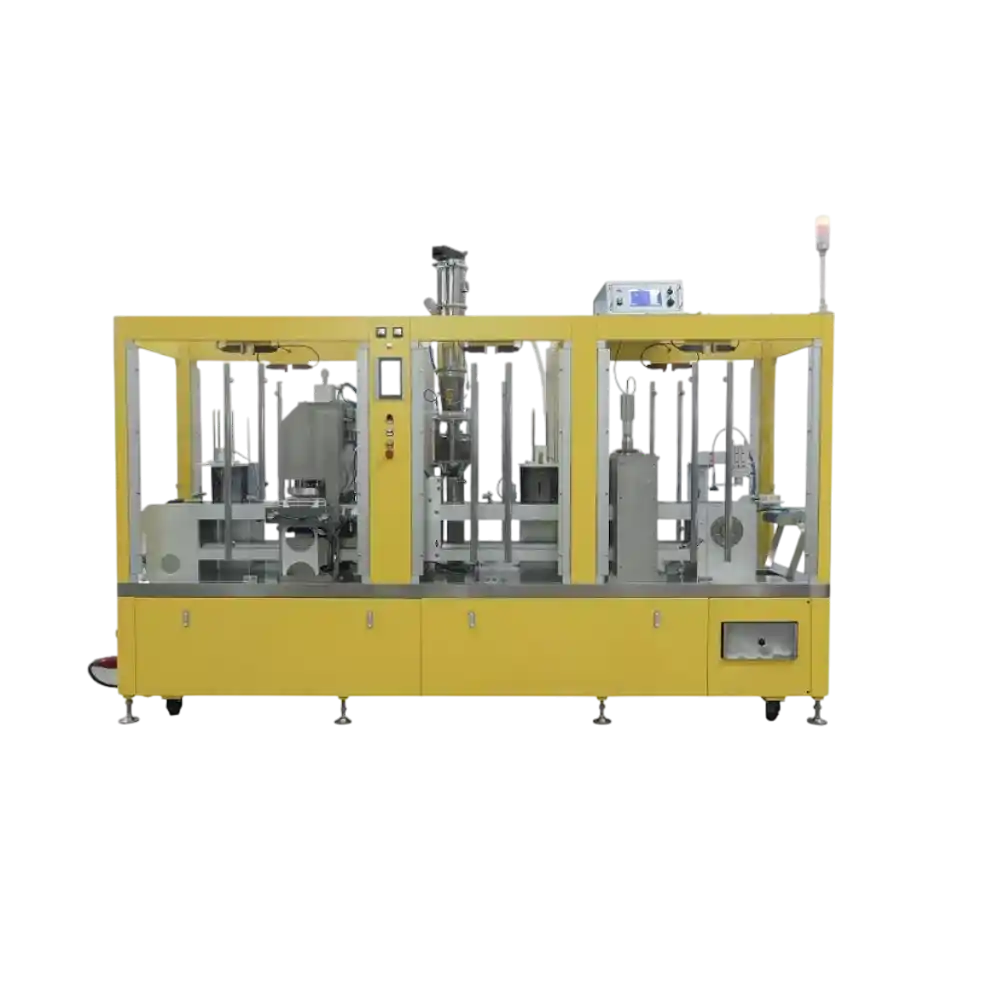

- Flexible Bag Sizes and Types

- This coffee filling system works with many bag styles – small single portions or bigger family packs. It shifts easily between them, maintaining speed alongside good results. Essentially, it adapts to what you need.

- High Production Capacity

- The UFO Drip Coffee Machine really shines when it comes to speed. It handles a ton of coffee bags quickly – perfect if you need lots made fast. Because things move so swiftly, companies get their orders out sooner, potentially boosting earnings.

- User-Friendly Interface

- Operators find the DTD model straightforward thanks to its simple controls – they can watch what’s happening and make changes without fuss. Because it’s so easy to learn, staff get up to speed quickly, meaning anyone can run the machine, making packaging flow smoother.

- Hygienic Design

- Keeping food safe is key when packaging it, so the UFO Drip Coffee Filler was built for easy cleaning. It’s made from stuff you can quickly wipe down and disinfect – no worries about spoiling your coffee! This machine follows all safety rules, guaranteeing a secure product for anyone who drinks it.

- Energy Efficiency

- Businesses care more about being eco-friendly these days, so we built the UFO Drip Coffee Machine to save energy. It runs on very little power – yet still brews great coffee – lowering bills also benefiting the environment.

How the UFO Drip Coffee Filling and Packaging Machine Works

This coffee machine fills drip coffee containers then seals them – it’s straightforward, really. It works like this:

- Coffee Bean Grinding (Optional)

- Some growers ship pre-ground coffee; however, others equip the UFO Drip Coffee Machine with a built-in grinder. Consequently, each brew starts with fresh grounds – retaining the coffee’s scent also its taste.

- Filling the Filter Bags

- The coffee maker brews, then carefully portions grounds into individual filters. It’s a consistent system; each filter gets precisely the same measure. Consequently, every bag holds equivalent coffee – same strength, same amount.

- Sealing the Filter Bags

- Once packed, a device closes the bags tight with a unique seal. Consequently, coffee stays inside – safe from spills or anything getting in.

- Packaging and Labeling

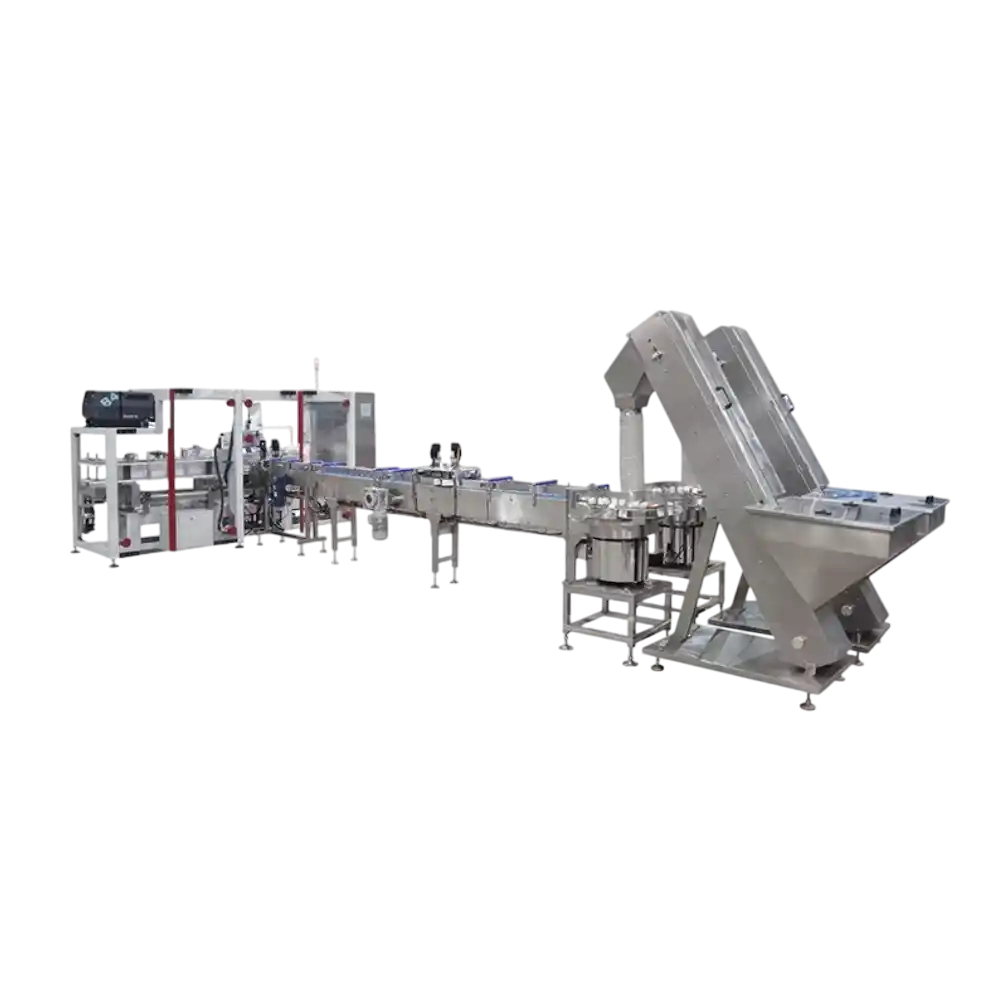

- The coffee machine works with labelers, even packaging lines. Sealed bags get stamped – details like what’s inside, when it was made, or when to use by. It makes things flow smoother while keeping everything legal.

- Quality Control and Inspection

- To keep things running smoothly, the DTD system has checks baked right in while packages are made. It uses sensors to spot issues – like bags with too little, too much, or a bad seal – so only flawless products move forward.

Applications of the UFO Drip Coffee Filling and Packaging Machine

This machine fills and packages drip coffee – it’s built for lots of different uses in the coffee world. Whether you make coffee, move it around, or run a smaller roasting business aiming for quality, this could be what you need. Here’s where it works well:

- Single-Serve Coffee Packs

- Folks craving a fast cup now dig those single-serve coffee bags – this UFO Drip Coffee Machine makes packing them a breeze. It handles the little bags effortlessly, getting them filled then sealed without fuss.

- Specialty Coffee Brands

- Good coffee deserves good wrapping. For those who roast special beans, how it’s packed matters a lot. This machine gently fills and seals each bag, keeping the flavor fresh while also making customers happy.

- Bulk Packaging

- The UFO Drip Coffee Machine doesn’t limit you to individual servings; it manages large coffee packages too. It adapts to various bag dimensions – whether you’re filling retail or wholesale orders.

- Private Labeling

- Coffee businesses often want to sell their own branded coffee. The UFO Drip Coffee Machine helps them do just that – customizing how things look, from the package itself to what’s printed on it. This way, shops maintain a consistent quality alongside their unique branding.

Advantages of Using the UFO Drip Coffee Filling and Packaging Machine

- Increased Production Efficiency

- The UFO Drip Coffee Machine handles everything – filling bags, sealing them up – so companies ditch tedious handwork. Consequently, they get coffee out the door faster, growing alongside customer needs.

- Consistent Product Quality

- Each coffee pack gets just the right amount, then tightly closed – so every one is similar. Folks come back when things are always reliable; it builds confidence in the brand.

- Reduced Labor Costs

- By taking over tasks, automation shrinks payrolls. With less staff watching things run – or doing the running themselves – companies can then channel energy into crafting better products instead.

- Improved Safety and Hygiene

- Built to stay spotless, this device cuts down on chances for anything unwanted getting into your coffee – it keeps things safe while packaging. That matters a lot when it comes to keeping up with strict rules about food safety, also giving people the quality they expect.

- Scalability

- Need to grow your business – whether you’re just starting out or already big? The UFO drip coffee machine adjusts to fit how much you make, simplifying things along the way.

Conclusion

For coffee makers wanting better packaging, the DTD machine fills and seals remarkably well. It boosts output, operates smoothly, then simplifies things for users. Businesses gain an edge by packing coffee fast – always the same way – with top quality, lowering expenses alongside workflow improvements.

Maintenance and Care of the UFO Drip Coffee Filling and Packaging Machine

To keep your UFO Drip Coffee Filler working its best – for years to come – routine upkeep is key. This avoids frustrating halts in production while guaranteeing each package of coffee meets your standards. It’s about smooth operation alongside reliable quality.

Routine Maintenance Tips

- Regular Cleaning and Sanitization

- Keeping coffee fresh involves food safety – cleanliness matters. Consequently, this drip coffee maker utilizes easily cleaned parts. To keep things tasting right, give the equipment a scrub following each use – especially where it fills or seals. Coffee grounds accumulating can change flavor also create risks.

- To keep the machine running its best, use specific cleaners – or try steam – to thoroughly disinfect inside, reaching every component.

- Lubrication of Moving Parts

- Keep the UFO Drip Coffee Filler working right by oiling its pieces often – this stops them from getting worn out. Specifically, give conveyor belts, fill spouts, also seals a good coating so everything runs smoothly. Less rubbing means parts last longer, therefore production flows without hiccups.

- Inspection of Sealing Mechanisms

- Freshness hinges on a good seal for those coffee bags. So, check the sealer bits often – make certain they work as intended. Seals don’t last forever; eventually they’ll need changing. To avoid flaws in what you make, verify temperatures are correct likewise confirm sealing pressure is set just right.

- Calibration and Adjustments

- Keep the coffee scale checked – it matters! Regularly adjust how much coffee goes into each bag so every one has just the right amount. This stops some bags from having too much while others don’t have enough, guaranteeing a consistent brew for customers. Also, examine the machine’s sensors, particularly whenever you switch coffees.

- Monitoring Electrical Components

- The UFO Drip Coffee Machine, like most things automatic, runs on electricity. Check its parts – wires, how everything connects, plus the controls – often to head off problems. A tidy control panel, clear of dust, ensures it works well while dodging shorts or digital hiccups.

Troubleshooting Common Issues

- Underfilling or Overfilling

- Sometimes bags don’t get quite enough coffee, sometimes way too much. Usually this means something’s off with how the machine is set up, or how quickly coffee comes out. Take a look at those settings – tweaking the coffee flow might be all it takes to fill each bag just right.

- Improper Sealing

- Bags failing to seal? It could be the heat, force, or something broken within the sealer itself. Give the sealer a once-over for any wear then tweak its controls. Also, confirm the bag material works with this machine.

- Jamming or Conveyor Malfunctions

- When things get stuck – or move too slowly – look for blockages throughout. Wipe down the conveyor, then inspect parts for wear or damage; fix what’s needed. Keeping belts well-oiled can ward off such problems.

- Inconsistent Packaging

- If filter bags aren’t placed just right, expect wonky package shapes – think creases or crooked seals. Double-check the bag loader setup; also, use good materials. Even a little shift in bag position means folds may be off, impacting how neat and secure everything looks.

Long-Term Care

- Scheduled Servicing

- Beyond routine upkeep, getting a qualified expert to inspect things now then is wise. They’ll gauge how well the machine runs, spot trouble brewing, also swap out tired components. Consistent pro tune-ups mean your equipment lasts longer while still working at its best.

- Spare Parts Inventory

- To keep things running smoothly, always have key repair pieces available – downtime costs money. Seals, spray tips, detectors, drive bands, plus gaskets are frequently needed. Electrical bits should be stocked too; when they fail, operations can halt.

The Environmental Impact of the UFO Drip Coffee Filling and Packaging Machine

Folks care more about a green footprint these days – especially when they buy coffee. So, quality matters, yet so does how brands treat the planet. The UFO Drip Coffee Filling and Packaging Machine helps with that.

Energy Efficiency

This machine cuts down on wasted energy – it runs efficiently without gulping power. Smart controls make sure electricity gets used solely when needed, so it doesn’t drain resources while waiting or resting.

Businesses save money – also lessen environmental impact – by using very little power. Consequently, they support greener production methods. Operating this way boosts a company’s image with customers who value sustainability.

Packaging Material Optimization

As folks look for ways to cut down on plastic waste, coffee companies are switching to greener packaging. The UFO machine handles different earth-friendly options – think compostable filter packs or recyclable wraps – so businesses can offer quality coffee alongside their commitment to the planet.

Waste Reduction

This device expertly fills then seals, curbing material loss. Because each bag gets just the right amount, defective products diminish alongside wasted coffee. Moreover, it cuts down on mistakes, so resources aren’t overused – packing becomes streamlined.

Market Trends and Future Outlook for Drip Coffee Packaging Machines

More people drinking coffee globally means we require better ways to package it. The UFO machine fills and seals single-cup portions – ideal for those wanting quality coffee quickly, because life moves fast.

Growth of Single-Serve Coffee

Expect fast growth in the one-cup coffee world. People want ease, mobility, moreover – fresh coffee when they’re out the door. Consequently, businesses are pouring money into new tech to handle this shift. The UFO Drip Coffee Machine fits right in; it fills, seals, then packages drip coffee quickly, directly addressing what customers now require.

Automation and Industry 4.0 Integration

As factories embrace new tech – automation, clever tools, instant updates on what’s happening – packaging will become a connected part of everything. The UFO Drip Coffee Filler packs easily into these modern setups, letting companies keep tabs on how well things are running, record production numbers, then use those insights to work smarter. Consequently, output gets better alongside greater command over how goods get made.

Sustainable Packaging Solutions

Coffee folks are really leaning into greener packaging – a shift that’s here to stay. Expect clever designs, similar to the UFO Drip Coffee Machine, adapting to things like plastic made from plants or filters you can simply compost. Businesses embracing this earth-friendly approach should do well as more shoppers prioritize sustainability.

Conclusion: The Future of Coffee Packaging

Coffee companies, whether big or little, gain speed, accuracy, likewise adaptability thanks to the UFO Drip Coffee Filling plus Packaging Machine – model DTD. As people crave better single-cup coffee while also caring about our planet, equipment similar to this one will undoubtedly shape how coffee gets packaged going forward.

Coffee makers such as the UFO Drip offer a way for businesses to work smarter – saving energy while keeping up with what customers want: good coffee, delivered easily, alongside a commitment to our planet.

As factories evolve alongside new tech, businesses doing things differently – with an eye toward protecting resources – stand to thrive amidst constant change.

Integrating the UFO Drip Coffee Filling and Packaging Machine into Your Business

Getting a UFO Drip Coffee Filling and Packaging Machine working well isn’t simply buying it then setting it up. For the best results – a good return on what you spend – consider how it fits with everything you already have.

Assessing Your Production Needs

Companies ought to figure out what they really need before getting a UFO Drip Coffee Filling and Packaging Machine. Things that matter include:

- Want more coffee, faster? As orders climb, don’t let bottlenecks slow things down. The UFO Drip Coffee Machine brews plenty – without cutting corners on taste.

- The UFO Drip Coffee Maker works with lots of coffee choices – different amounts, grinds, even bag sizes. So, when you expand into things like single cups or special flavors, adding them won’t be tricky.

- Got automation going on? The UFO Drip Coffee Machine slots right in. Not so much? Getting things running smoothly could mean a bit of staff learning alongside new bits – think moving belts, labels, checks for quality.

- Think about where you’ll put the UFO Drip Coffee Machine. It doesn’t take up a ton of room – not like bigger factory stuff – yet it requires enough area to work on, keep running smoothly, or perhaps grow later. Make sure the location helps things move quickly while also fitting around related tools such as grinders, belts, or packaging machines.

Customizing to Your Needs

You can adapt the UFO Drip Coffee Filling and Packaging Machine to fit how you do things. Companies collaborate with vendors to adjust what the machine offers

- How fast things get filled depends on how much you’re making – you may want to tweak that rate, alongside the amount per go. This coffee machine lets you set exactly what speed and fill level work best for you.

- Considering a shift to greener bags or packaging? Double-check your equipment works well with them. Newer earth-friendly choices might need unique heat settings or how they’re fed into the machine – adjustments are often possible.

- To make things run even smoother, this coffee machine connects with other equipment – like labelers, checkers, or final packagers. It gets everything working in sync, cutting down on delays while boosting how work flows.

Employee Training and Adaptation

Getting people ready for our new, automatic way of making things is vital. The UFO Drip Coffee Machine may be simple to use, yet staff need complete instruction on these points:

- To keep things running well, folks need to know the ins and outs of this machine – how to get it going, what each setting does, also how to fix hiccups. Getting acquainted with the controls and knowing what it can do is key for anyone operating it.

- Keeping things running smoothly means less interruption, so staff need lessons in simple upkeep – wiping down surfaces, doing regular checks. They ought to know what parts demand focus alongside how to fix typical problems.

- Keeping everyone safe while this runs matters a lot. Staff need lessons on stopping things quickly if trouble starts – also, learning how to use the equipment without getting hurt. Frequent practice alerts plus obvious warnings near the device reinforce what could go wrong.

Key Considerations for Coffee Producers When Choosing Packaging Machinery

Coffee businesses thinking about a machine – like one that fills and seals drip coffee bags – should weigh a few things first

Weighing what things cost against what good they do

Good machines cost a bit upfront, yet they generally save money over time. Consider this:

- The coffee machine cuts labor costs by doing the work people used to do. It packages a lot of coffee quickly, so fewer staff are needed – they’re available for different jobs instead.

- This machine works quickly, accurately – boosting how smoothly things run. It fills and seals containers faster, so you get more product packed each hour, yet maintain standards.

- Forget mistakes – machines deliver. Errors in filling packages mean unhappy customers. This coffee machine fills each package just right, time after time, building trust in the brand.

- Filling correctly means less mess. Too much coffee spills; too little disappoints customers – potentially costing money with returns. This machine helps get amounts right, so resources aren’t squandered.

Scalability

Should your coffee business boom, think about whether equipment can keep up. The UFO Drip Coffee Machine grows alongside you. Should your offerings grow, or output rise, this machine adjusts right along with you. Because its build is in sections, boosting capabilities or tweaking settings doesn’t demand starting from scratch.

Regulatory Compliance

Keeping coffee safe – both the product itself alongside its wrapping – matters most to those in the business. This machine helps hit tough cleanliness goals. Still, companies need to double-check that everything used for packing follows regional rules, specifically how things are labeled, whether packages stay sealed, and keeping contaminants out.

Consumer Trends

Coffee lovers change their minds quickly. These days, they really care about where coffee comes from, how good it tastes, but also want it to fit easily into their lives. Need a way to meet what customers want? The UFO Drip Coffee machine lets manufacturers pack individual coffee portions using materials kinder to the planet – keeping each serving flavorful and fresh. It’s a smart move if you aim to benefit from more people seeking quality items alongside environmental responsibility.

Challenges in Adopting Automated Packaging Solutions

Despite the many benefits, adopting an automated packaging solution like the UFO Drip Coffee Filling and Packaging Machine can come with certain challenges:

Initial Capital Investment

Investing in robust factory equipment often requires a large upfront sum. Smaller companies especially might struggle with the expense. Though loans exist, carefully weighing potential gains against costs is vital for lasting success.

Integration Complexity

Getting new equipment working alongside what you already have isn’t always simple, notably if automation is fresh territory. The UFO Drip Coffee Machine requires thoughtful placement within your workspace; anticipate where things might slow down. Skilled installers coupled with engineering expertise make for a smoother setup.

Maintenance Costs

Machines may lessen hands-on work, yet they require upkeep. To run smoothly, they demand routine checkups alongside some part swaps. Consequently, companies should plan for these continuing costs as a normal business expense.

Changing Market Demands

Consumer tastes in coffee are always changing, so those who grow and sell it need to be quick on their feet. The UFO Drip Coffee machine adjusts easily when packaging or products themselves get a makeover. Still, companies should watch what customers want – whether that means switching to individual servings or using eco-friendly packaging – to confirm their equipment can handle it.