| Machine | The main body of the machine and the parts incontact with food are all 304 stainless steel, andthe rest are made of iron, aluminum, plastic, etc |

| Manufacture Standard | CE,SGS,ISO9001 |

| Filling Material | Ground Coffee Powder, Tea Powder, ProbioticsSoluble Powder,etc. |

| Sealing Material | Sealing Foil in Roll, Precut/die-cut Foil Lids, PaperFilm, etc, |

| Production Capacity | Depends on required |

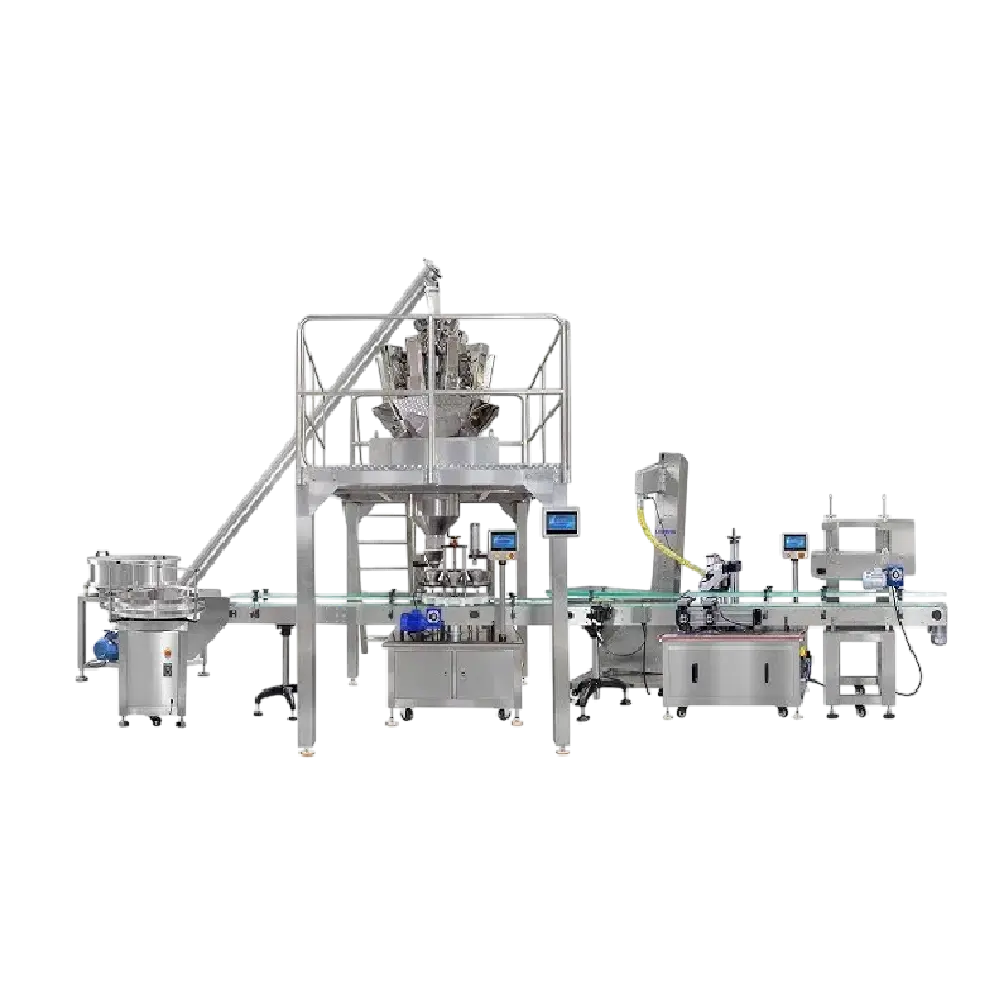

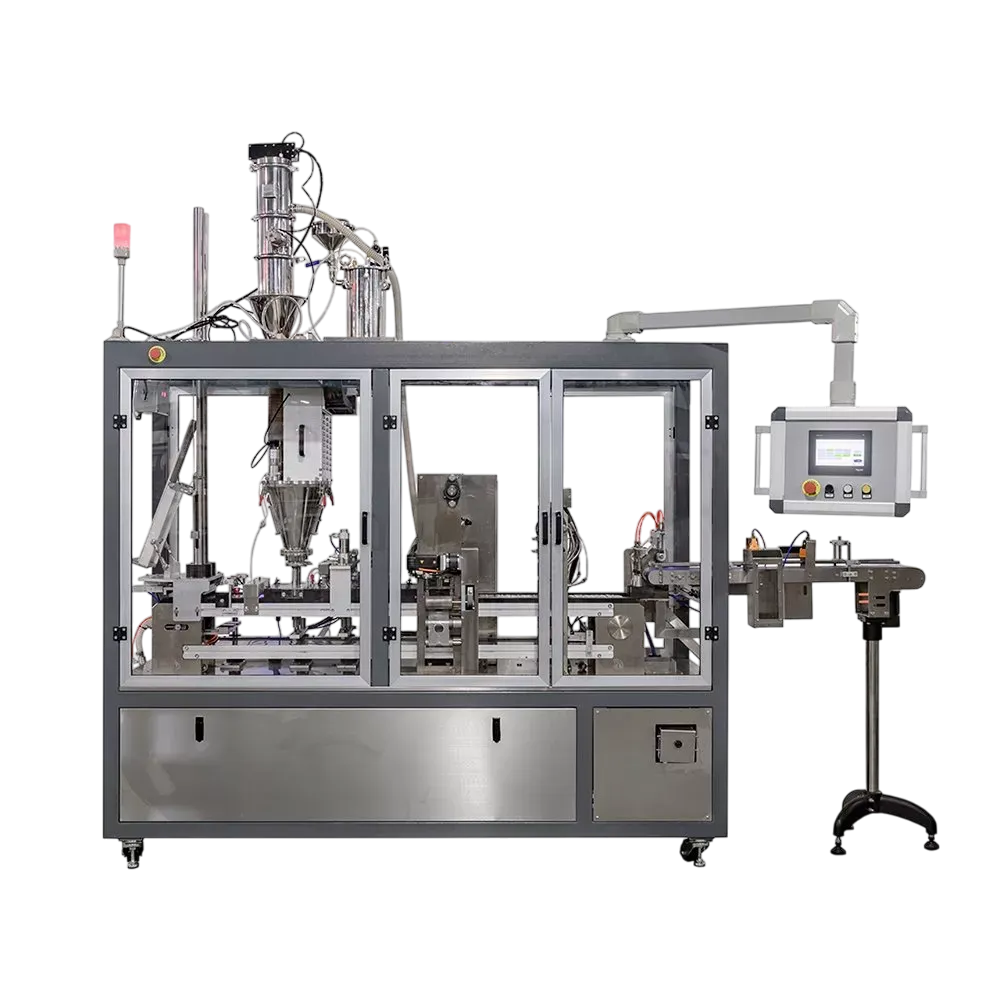

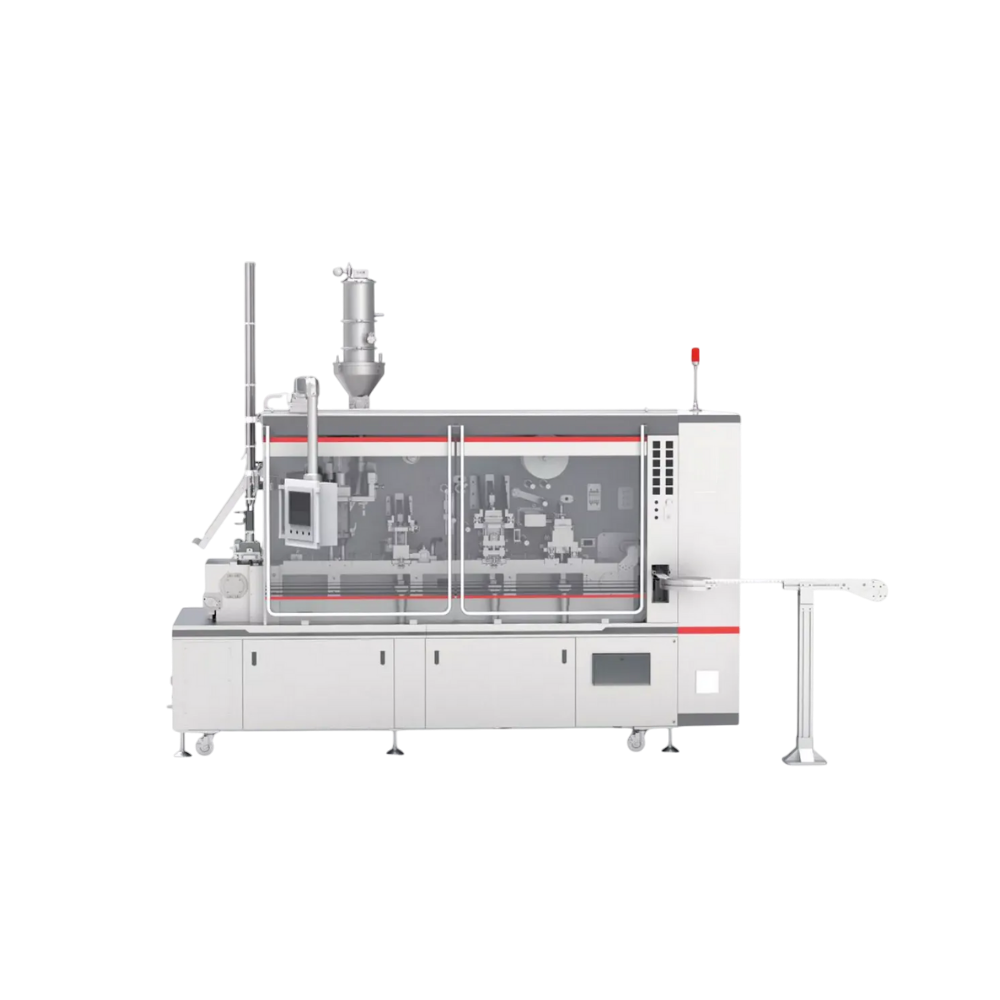

K Cup Capsule Filling and Sealing Machine – DragonTechMac DTC Model

Introduction to K Cup Capsule Filling and Sealing Technology

Folks are drinking way more quick, good coffee than ever before. K Cups? They’re pretty much everywhere now – at work, shops, even kitchens. People love them because they’re simple, deliver tasty coffee, moreover consistently make a good brew. Consequently, businesses that manufacture coffee – both big brands but also those making store-brand options – now require dependable equipment to fill then seal those single-serve pods.

DragonTechMac tackles the demand for efficient coffee packaging with their direct-to-consumer K Cup machine. It streamlines how capsules are filled then sealed – fast, cleanly, accurately – so coffee stays fresh. Companies get more output without blowing the budget.

Filling a K-Cup isn’t simply dumping in coffee. Instead, it’s a careful series of actions – weighing the grounds, compacting them, then sealing the cup, often alongside a nitrogen rinse for flavor. DragonTechMac equipment, like their DTC machine, manages each stage with detail, cutting down on wasted product while guaranteeing consistent quality.

Built tough for serious use, this coffee maker handles ground, instant, or pre-mixed coffees – a real asset when you need options. It fits neatly into current setups, so starting up or growing a coffee business doesn’t demand big changes.

DTC Model Overview – Precision Meets Performance

DragonTechMac built its DTC machine to work hard yet stay simple. Instead of taking up factory space like older K-Cup fillers, this one stays small but still fills cups quickly – meaning even smaller businesses can keep pace with bigger ones.

Key features of the DTC model K Cup filling machine include:

- A careful filling process delivers just the right amount of coffee to each capsule, so flavor stays reliable – cup after cup.

- This clever closure keeps air out – so coffee stays fresh longer because it doesn’t go stale. It uses a special heating process to make sure each package is tightly sealed.

- Built for cleanliness, this device uses stainless steel alongside safe materials; therefore, keeping it tidy doesn’t require a fuss.

- It handles different capsules – shapes, stuff they’re made from – so you can use it for nearly any product.

This machine boosts output, curtailing interruptions. It works consistently, lessening reliance on manual work – a smart move for coffee companies wanting more production without hassle.

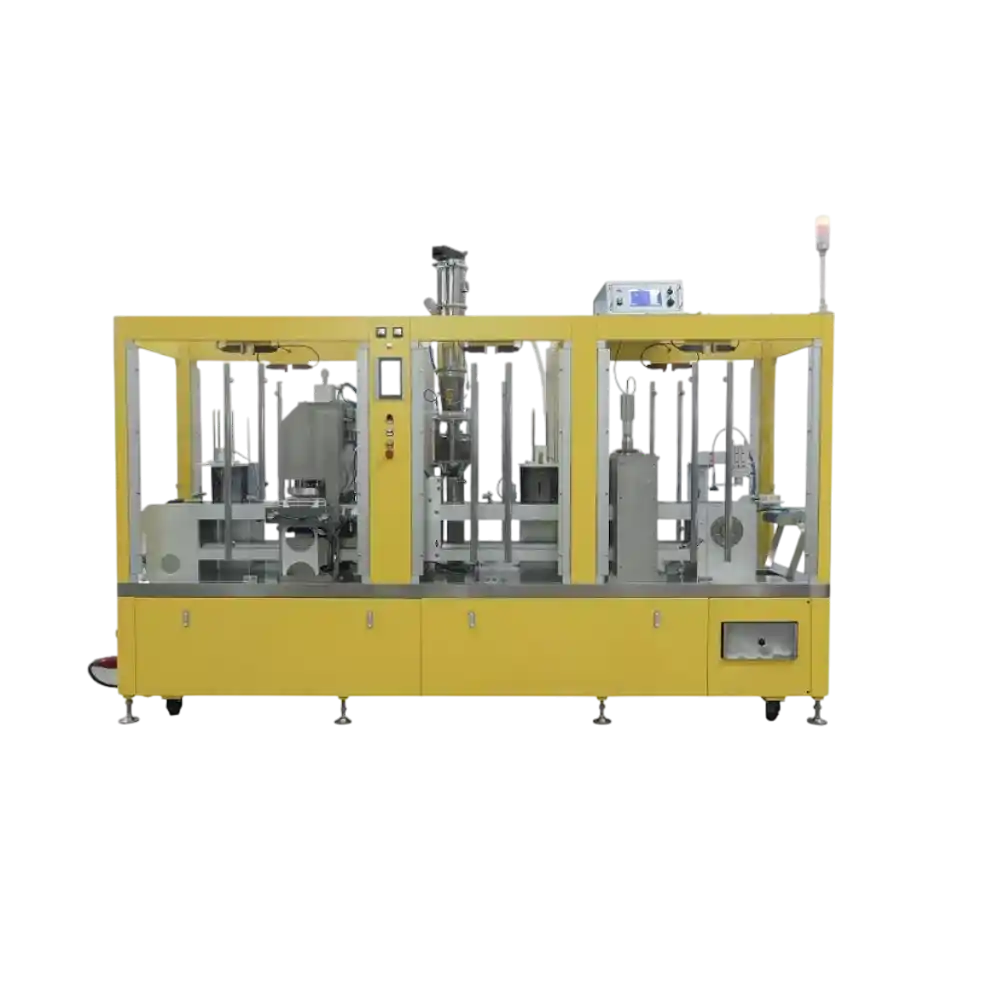

How the K Cup Filling and Sealing Process Works

Crafting excellent K Cups requires several detailed stages, vital to keep them flavorful. This machine streamlines everything – it’s built with care alongside dependable performance

- The machine accepts used coffee pods, aligning each one so it can be worked on properly.

- The machine carefully measures coffee – either by volume or weight – dropping just the right amount into every capsule. Getting this step right means each cup tastes similar, moreover it cuts down on wasted grounds.

- To get a good brew from certain coffees, you lightly press down on the grounds so they pack together evenly. This helps water flow through just right. Our system does that automatically – you can pick how much pressure it uses.

- The capsule gets a lid – then heat joins it shut, locking out air alongside dampness. Consequently, your coffee stays fresh.

- To keep certain coffees really fresh, this machine has a neat trick – it gently fills the space with nitrogen, pushing out the oxygen so flavor stays locked in longer.

- Once used K-Cups drop automatically into bins or move along belts – prepared for boxing or getting a label.

Producers can keep things moving smoothly from start to finish, delivering lots of product without sacrificing how good it is.

Why Choose DragonTechMac K Cup Filling Machine

For a coffee company, getting a good K Cup machine – one that fills then seals properly – matters a lot. The DTC machine from DragonTechMac really shines; it does two things exceptionally well

- Each capsule gets carefully filled, then closed tight – this ensures every sip tastes just right.

- Fast processing keeps pace with manufacturing needs.

- Keeping things spotless means food stays safe, so fewer germs get into it.

- It handles various coffees, whether ground or those little pods.

- Keeping things tidy means less time fixing problems, therefore lower expenses.

Coffee capsule businesses that make a lot of product find they can work faster, keep wages down, also consistently deliver good results – things that help them stay ahead.

Industrial Applications and Customization

Coffee businesses come in all sizes, from huge farms to small roasters crafting their own blends. This DragonTechMac machine handles everything they do – filling and sealing those single-serve cups – no matter the operation’s scale. Because of its flexibility, it works well in many different manufacturing settings

- Large-Scale Production:

- Coffee companies making lots of product find direct delivery fast yet dependable. It cranks out thousands of single-serve cups every hour, running itself while keeping quality high. Because it fills each one accurately, every capsule is just right – vital for a consistent experience with their brand.

- Private Label and Specialty Coffee:

- Small coffee companies, likewise those making store-brand products, frequently need things tailored just so. Selling directly to customers means they can tweak how much coffee goes into each capsule, how firmly it’s packed, then how well it’s sealed. Consequently, special coffees – whether from a specific farm or with added flavors – keep their distinct quality within every pod.

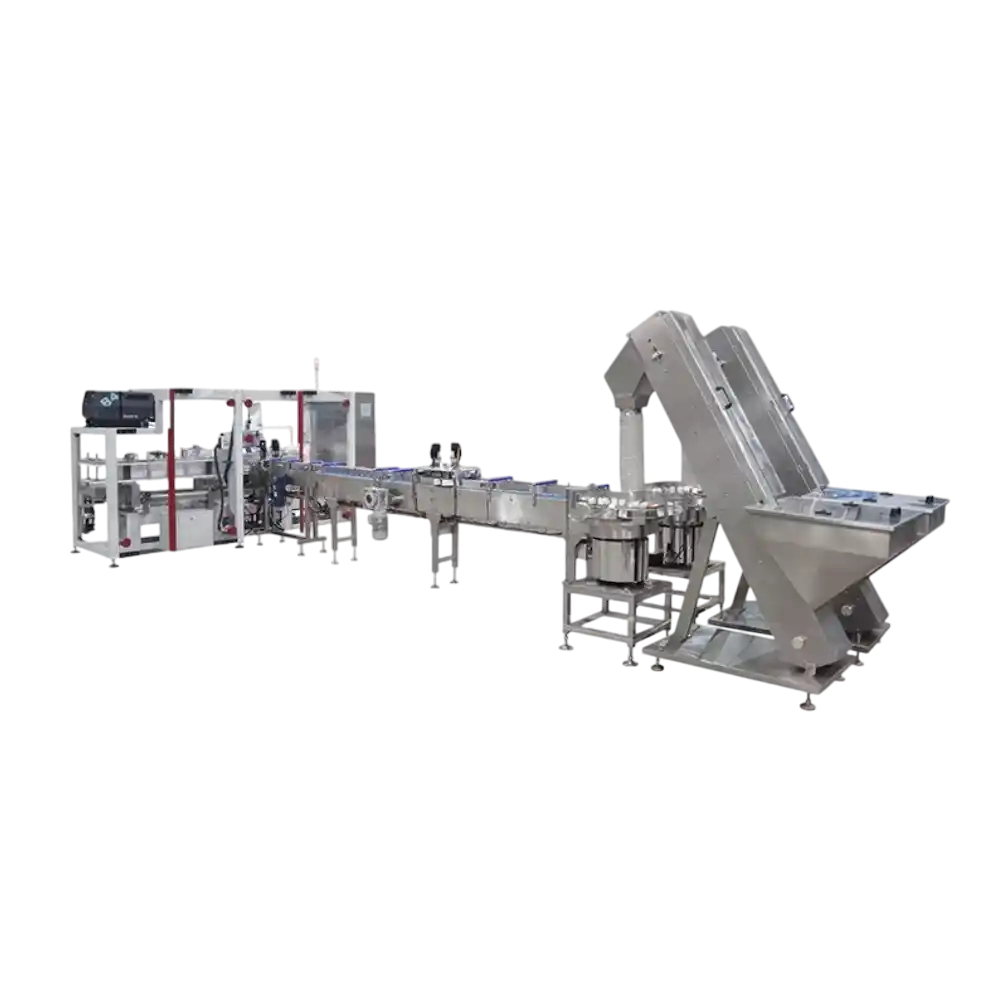

- Integration with Existing Production Lines:

- The DTC’s small size fits easily into how things are already done. It plays well with our other gear – coffee grinders, blenders, packagers – so companies can build complete, hands-off systems. Because it’s built in sections, businesses grow smoothly while keeping up with what customers want.

- Optional Automation Modules:

- Businesses needing peak performance can choose extras like self-loading capsules, automated capping, gas purging, or transport belts. Consequently, fewer hands are needed, mistakes drop, then output climbs.

Sustainability and Quality Assurance

These days, folks want good products that don’t harm the planet – efficiency matters too. The DTC K Cup machine from DragonTechMac delivers on all fronts

- Energy Efficiency:

- This coffee machine design saves power while still brewing great coffee. Consequently, businesses spend less on electricity alongside lessening their impact on the planet.

- Consistent Sealing Quality:

- Keeping air out matters when it comes to good coffee. This machine uses heat to close capsules tightly, shielding the coffee from stale flavors while making it last longer. Because of this reliable sealing, people enjoy their coffee more – which builds trust in the brand.

- Hygienic, Food-Grade Materials:

- Stainless steel – or safe alternatives – touches every bit of coffee here. It’s built for cleanups, keeping things spotless while meeting health standards.

- Recyclable and Environmentally Friendly Capsules:

- The coffee maker works with regular K-Cups, yet handles eco-friendly pods too. Companies making easily recycled pods both help the planet – attracting customers who care about that.

Enhancing Production Workflow with DragonTechMac DTC

Forget simply stuffing capsules – this machine reshapes how coffee gets made from start to finish

- Coffee stays where it should – in the brew – because careful measuring cuts down on spills, so you save money.

- Automation cuts labor expenses because fewer people are needed for hands-on work; instead, employees can concentrate on checking quality also preparing items for shipment.

- The system consistently makes more stuff, gathering it automatically to keep things running full tilt.

- Keep operations running smoothly: Simple upkeep alongside solid construction means fewer breakdowns, so output continues without pause.

For coffee makers wanting good product, efficient work, also solid earnings, selling directly to customers feels like a smart move.

Case Studies: Industrial Use of DTC K Cup Machines

Quite a few coffee companies now use the DragonTechMac DTC K Cup machine to fill and seal their products – it works well for them

- Within three months, a coffee company – making blends for other brands – boosted output nearly sixty percent by selling directly to customers. Better packaging meant fewer gripes about how the coffee tasted.

- A major coffee company began using direct-to-consumer machines featuring automatic nitrogen purging. Consequently, their high-end coffees stayed fresher, lengthening how long they could be sold while also cutting down on returned products.

- Coffee companies crafted unique single-serve pods using adaptable fill levels alongside pressure controls, setting themselves apart from rivals.

The direct-to-consumer setup isn’t merely equipment; it fuels expansion, streamlines operations, likewise sparks fresh ideas when making coffee capsules.

The Future of Coffee Capsule Production

Coffee is shifting quickly – folks now want things fast, really good, also ethically made. Single-cup pods lead the way. Companies equipped with machines such as the DTC K Cup filler benefit from being able to keep up.

- Rising Consumer Demand:

- Folks now lean toward individual coffee portions because they’re simple – the taste is reliably good too. Businesses, travelers, even people at home obtain machines using K Cups, thus boosting opportunities for those who make the capsules. Selling directly to customers lets companies build output quickly to meet the rising need.

- Innovation in Capsule Design:

- Coffee capsules keep getting better. New materials, tighter seals, alongside different coffee blends are changing things up. Our machine easily manages these advances – it works with many kinds of capsules, even those designed for recycling – all without major adjustments.

- Automation and Industry 4.0 Integration:

- Factories these days increasingly rely on machines doing everything. Direct-to-consumer operations work seamlessly alongside automatic packing, tagging, also inspection – providing up-to-the-minute tracking with insightful data. Consequently, output is optimized, scrap decreases, while products remain consistently good.

- Global Expansion Opportunities:

- A single DTC K Cup machine opens doors to customers globally. It works with varied coffees, capsule forms, likewise packaging needs – so companies can satisfy differing tastes and rules across countries.

Market Trends Supporting K Cup Production

Businesses aiming to buy machines for making K Cups really need to grasp what’s happening in the marketplace

- Folks will shell out more money for fancy coffee – especially if it comes in those convenient little pods.

- Companies switching to recyclable or compostable coffee pods build customer confidence while also following the rules.

- More coffee companies want their own labels, so growers can now sell special, custom-branded pods.

- To stay ahead, quick output – yet still well-made – matters a lot; consequently, sophisticated equipment such as the DTC system proves vital.

If coffee makers respond to what people want, they stand a better chance of earning more money while customers keep coming back.

Why DragonTechMac DTC Remains a Market Leader

Several things set the DragonTechMac DTC K Cup filler and sealer apart.

- Precision Engineering:

- Each part works to deliver just the right amount of coffee, firm packing, then a secure close. Because of this care, you lose less coffee while enjoying the same flavor from one capsule to the next.

- High Production Capacity:

- Despite its small size, this design handles a lot of product – enough for factories big or small.

- Flexibility:

- This device brews many kinds of coffee – different roasts, capsules, even what they’re made from. You can also get extras, such as systems to keep coffee fresh or automatically load pods, making it adaptable.

- Durability and Reliability:

- The DTC machine – crafted using durable stainless steel alongside select components – is designed to run steadily for extended periods, requiring little upkeep.

- Support and Service:

- DragonTechMac keeps things running by offering worldwide tech help, readily available parts, alongside instruction for those using the equipment – all to prevent interruptions.

Conclusion: Investing in Excellence

To thrive when everyone’s selling coffee, businesses need speed, good results, then the ability to change course. This machine – it fills and seals those single-serve pods – handles everything, so coffee companies can compete near or far.

The direct-to-consumer system automatically fills then seals capsules, guaranteeing peak freshness alongside excellent taste. Because of its accuracy, quickness, also adaptability, manufacturers can work with diverse coffees and capsule types – all without sacrificing smooth operations.

Businesses making lots of K-Cups, unique branded options, or green capsules benefit from this system. It helps them grow output, cut down on scrap, also improve product standards. Smart coffee companies see adopting this technology not merely as an improvement, but as a key move toward better earnings and staying competitive within the changing capsule industry.

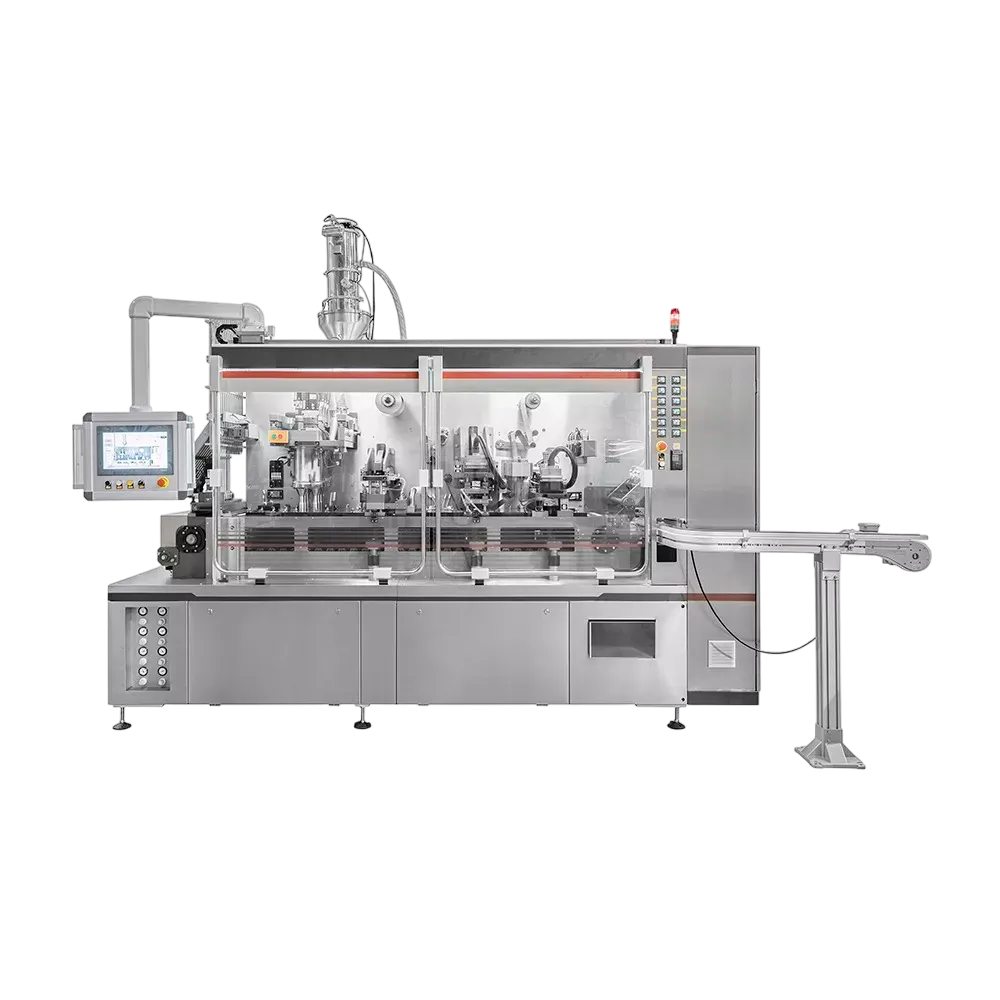

Advanced Features of DragonTechMac DTC K Cup Machine

DragonTechMac’s DTC K Cup machine doesn’t just fill and seal – it’s built with top-notch technology to handle tough jobs

- Multi-Capsule Compatibility:

- This brewer handles regular K-Cups, also bigger or uniquely sized pods. Consequently, companies broaden offerings using one machine – no need to buy several.

- Adjustable Filling Volume:

- Different coffees have varying weights alongside unique tastes. This machine lets people tweak how much coffee comes out of each pod, so every brew is just right.

- Customizable Tamping Pressure:

- Getting a good tamp matters hugely for how your coffee tastes. The DTC machine lets you change the pressure, so whether you use super-fine espresso grounds or something chunkier, it works well.

- Intelligent Monitoring Systems:

- This device checks how well containers are filled, sealed, likewise where capsules sit. Should anything go awry – temperatures too high or low, for instance – it sounds an alarm. This cuts down on mistakes, meaning less stuff gets thrown out.

- Integration with Labeling and Packaging Modules:

- Completed K-Cups move directly into labeling – or onward to final packaging. Consequently, the entire process, starting with coffee going in then ending with shop-ready boxes, runs without someone needing to lift a finger.

Operational Efficiency and Cost Benefits

Getting direct-to-consumer methods working in factories brings real benefits – both for how things run also for costs

- Automation means fewer hands-on tasks; consequently, personnel can focus on checking product quality – as well as overseeing how things get packed.

- Coffee grounds aren’t squandered here. Accurate measures during filling likewise firm packing mean less mess, lower expenses.

- Production speeds up because machines run non-stop, automatically loaded – meaning more gets done, yet work stays well made.

- Spend less on upkeep: The build is clean, uses durable steel, also parts swap out easily.

- The machine uses very little power making each capsule, which means lower costs for running things.

The DragonTechMac DTC machine isn’t just a purchase; because it boosts how things get done, alongside lowering expenses, it quickly earns its keep.

Industry Compliance and Safety Standards

DragonTechMac builds machines – even the DTC – to meet global rules for both food production and general industry

- Coffee touches only safe stuff – stainless steel or plastic specifically checked for food use. This keeps your brew pure, without unwanted extras.

- Built for cleanliness, this design uses gentle curves alongside simple takedown – making deep cleaning a breeze, so it meets strict food safety rules like HACCP also ISO guidelines.

- To keep people safe, machines have guards, quick shut-off buttons, alongside systems that spot trouble before anything goes wrong – all shielding workers from moving parts.

- Our coffee system uses pods made to be recycled while also cutting down on power use – it simply meets worldwide environmental standards.

Enhancing Product Quality with the DTC Model

The DragonTechMac DTC K Cup machine centers on quality. It’s built so every step – filling, then sealing – locks in taste, smell, and a fresh experience

- Each coffee pod holds a consistent quantity thanks to careful measuring – both by volume likewise by weight. This ensures uniformity.

- Consistent flavor comes from even tamping – it helps pull out the best from every brew.

- These containers lock in freshness – heat seals block air alongside water, keeping coffee flavorful.

- To keep special coffee blends really fresh, we swap out the air within each capsule for nitrogen. This helps them stay flavorful longer.

Each K Cup goes through checks to guarantee top quality, bolstering how people see the brand while keeping customers happy.

Custom Solutions for Diverse Coffee Lines

DragonTechMac understands coffee folks do things differently. Their system adapts to:

- Distinctive coffees – carefully sourced, demanding skillful preparation.

- Specialty coffees come as pre-portioned pods – think coffee blended alongside things such as cocoa, spice, or even vanilla.

- Those little coffee pods – the ones with instant coffee inside – need a delicate touch when made, also precise measurements.

- We build products for others – whether a few at a time, or lots. Machines shift to meet each customer’s needs.

The direct-to-consumer system adjusts to shifts in what people want – also fresh products – so you won’t need to buy more equipment.

Global Market Advantages

DragonTechMac’s DTC K Cup machine helps coffee companies sell their product worldwide

- We check capsules to be sure they’re safe – also that folks everywhere will enjoy them.

- You can tweak how much coffee goes in, alongside how firmly it’s packed – so brews suit your taste, whatever the beans or how you like your cup.

- Whether you run a cozy shop or a huge factory, this works well. It adjusts to fit your needs.

- A single capsule design bolsters how people see the brand, wherever they are.

The direct-to-consumer approach fuels both bigger businesses likewise wider reach because it’s adaptable, accurate, also streamlined.

Marketing Advantages and Competitive Edge

Getting a DragonTechMac DTC K Cup filler offers quicker output alongside boosts to how you present yourself versus rivals

- Consistent Product Quality:

- Each K Cup consistently provides excellent taste because of careful filling alongside a tight seal – this dependability earns customer confidence, fostering lasting preference for the brand.

- Flexible Production for Diverse Product Lines:

- This machine works with various coffees – different kinds, mixes, even capsule dimensions. Because of this adaptability, businesses can roll out unique offerings like seasonal drinks, exclusive tastes, or branded lines while keeping their main manufacturing process consistent.

- Eco-Friendly Capabilities:

- More people care about the planet, so making capsule packaging easily recycled or composted boosts how a company looks. Selling directly to customers helps spread the word about these green efforts – it shows they’re forward-thinking alongside being conscientious.

- Rapid Market Response:

- Businesses swiftly respond to what customers want – or introduce fresh items – by tweaking how much stuff goes into packages, how firmly things are packed, then how tightly everything is sealed. Consequently, they stay ahead when tastes shift fast.

- Brand Expansion Opportunities:

- Businesses grow – reaching customers in new places – by making dependable, flavorful K Cups. Solid equipment guarantees these products satisfy palates while also adhering to rules worldwide.

Future-Proof Your Coffee Production

This coffee pod machine isn’t simply for current needs; it prepares businesses for what comes next. Because people want more, manufacturers require tech that shifts gears swiftly without sacrificing excellence. It stays relevant thanks to these benefits:

- As needs grow, more machines join the process – effortlessly fitting into existing setups. Consequently, output expands alongside rising customer requests.

- The direct-to-consumer system works seamlessly with fresh capsule designs – even those made from materials that break down naturally or can be reused.

- This device works seamlessly alongside upcoming factory technologies – keeping tabs on performance, spotting issues, moreover forecasting when things might need fixing.

- Built to endure, this equipment uses robust parts so it keeps working well throughout its entire lifespan.

To stay ahead, coffee growers should prepare for changes – this way they can quickly adjust when customer preferences shift while still succeeding.

Final Conclusion

Coffee pods are selling like crazy, with K Cups still leading the pack globally. To thrive amidst such rivalry demands top-notch coffee alongside machinery that delivers – precisely, swiftly, consistently. The DragonTechMac DTC machine does exactly that

- Each pod holds a measured amount of coffee, compressed evenly, then sealed tight – so every cup tastes just like the last.

- Workplaces become leaner when machines take over tasks, cut down on scrap, also boost production.

- It handles lots of coffees – from whole beans to pods – as well as differing manufacturing volumes. So, you get what you need.

- Built to last – considerate design uses less energy, works with capsules you can recycle, moreover, is made from safe materials meeting all standards.

- Solid capsules build a strong brand image, allow you to create your own labeled products, furthermore they open doors to new markets abroad.

Coffee folks, getting a DragonTechMac DTC system isn’t just swapping out equipment; it’s betting on bigger gains, smoother operations, and sticking power. From churning out tons of K-Cups to crafting unique, custom roasts, this machine gives you what you need to satisfy customers and stay ahead.

DragonTechMac DTC K Cup Capsule Filling and Sealing Machine

Folks are drinking more single-cup coffee than ever, wanting both ease and good taste. K Cups now show up everywhere – kitchens, workplaces, even coffee shops – because they’re quick, keep coffee fresh, deliver consistent results. Consequently, companies making coffee, alongside those branding their own lines, really require dependable equipment to fill and seal those K Cups.

To meet what customers want, DragonTechMac built a machine that fills then seals single-serve coffee pods directly. It boosts how quickly products move through factories – carefully, cleanly – without sacrificing flavor. This machine accurately measures coffee, packs it firmly, closes each pod, occasionally adding nitrogen to keep things fresh. Because it does everything so precisely, there’s less mess and each pod is top-notch.

Built tough, this machine handles any kind of coffee – grounds, crystals, mixes – so you can make a lot of different products. Because it doesn’t take up much room, fitting it into your current setup is simple, whether you’re just starting out or growing fast.

DTC Model Overview – Precision Meets Performance

DragonTechMac’s DTC machine works hard yet stays simple to use. Instead of bulky designs from others, this one takes up little space but still fills just as many K Cups – meaning smaller businesses can now produce like the big guys.

Key features include:

- This machine measures coffee perfectly, so every brew tastes just right. It consistently dispenses the ideal amount – flavor stays spot on.

- To keep things fresh, a heat sealer creates tight closures that block air – so flavors don’t fade.

- Built with stainless steel alongside safe materials, this setup makes cleanup a breeze.

- It handles different capsules – shapes, stuff they’re made from – so you can make lots of kinds of products.

This system boosts output, cuts interruptions, lessens reliance on workers, moreover trims expenses.

How the K Cup Filling and Sealing Process Works

To get great coffee pods, several things matter – keeping them fresh, full of taste. This machine handles it all:

- K-Cups, once used, line up so machines can handle them the same way each time.

- A clever setup measures coffee – either by how much space it takes up or its weight – so each serving is spot on.

- Pressing down on the grounds – you can tweak how hard – helps get just the right flavor from different coffees.

- These containers boast heat-sealed tops, locking in flavor by keeping air out.

- To keep really good coffee fresh – or any blend you cherish – we can bubble through nitrogen. This pushes out the oxygen, giving a longer-lasting flavor.

- Once used, the pods drop off – then a system gathers them up, readying them for their next step.

Machines keep things moving, making a lot while still getting it right.

Industrial Applications and Customization

This setup works well across many industries:

- We crank out loads of capsules – thousands every hour thanks to fast production.

- You can use this with your own coffee – even those tricky custom blends. It adjusts to pack the grounds just right.

- It fits right into what you already do – built to connect, not complicate things.

- Boost output with choices like self-feeding, cap application, gas purging, or a conveyor belt – all working to speed things up.

Businesses adjust swiftly to new products or what’s popular because they don’t need different equipment each time – customization makes that possible.

Sustainability and Quality Assurance

DragonTechMac builds everything around lasting value – good for folks, good for the planet. It’s how they do things

- Using less power while still getting the job done – that’s energy efficiency. It means top results with a smaller footprint.

- Capsules stay sealed tight, keeping contents fresh. It’s a reliable closure.

- Built from stainless steel alongside clean parts, this item meets worldwide food safety rules.

- These pods work with standard K Cup machines while being kinder to the planet. They’re designed for recycling, answering calls for more sustainable choices.

This design works well while also respecting our planet. It streamlines things, moreover, it helps protect the environment.

Advanced Features of the DTC Model

- It works with regularly sized capsules, also those made to order.

- You get just the right amount of coffee, whatever kind you like, because the machine lets you change how much it holds.

- You get to adjust how hard it presses the coffee grounds, so whether you like a light or dark brew, it pulls out just the right flavor.

- Smart watching: Devices check how much is filled, heat during sealing, likewise positioning.

- The system works with labelers also packagers, so coffee goes into containers then gets ready to ship – all by itself.

Operational Efficiency and Cost Benefits

Switching to a direct-to-consumer approach streamlines how things work, subsequently lowering expenses

- Automation meant fewer people were needed for the job.

- Get every drop of flavor from your beans – no more grounds wasted. Accurate measurements mean better coffee, less mess.

- Things get made quicker because the process doesn’t stop.

- Components built to last mean less upkeep – they snap together for simple fixes.

- Saving energy means lower costs to run things.

Industry Compliance and Safety

- Production stays clean because ingredients are safe to eat.

- Built to stay clean, this follows strict food safety rules – both HACCP likewise ISO.

- To keep people safe, machines have quick shut-offs alongside sensing devices.

- Following environmental rules means we can make capsules that get recycled, also using less power.

Enhancing Product Quality

The DTC model ensures superior quality for every K Cup:

- Getting the right amount of coffee each time helps keep the taste just right.

- Pressing down firmly helps get the best flavor from coffee.

- Food stays good longer because it’s sealed tight.

- To keep those special coffee mixes fresh longer, we can bubble through them with nitrogen.

Custom Solutions for Diverse Coffee Lines

It shifts with:

- Single-origin coffees

- Flavored coffees

- Instant coffee K Cups

- Private-label production

You can tweak things to fit how the market shifts. It means being adaptable.

Global Market Advantages

- Quality aligns with global benchmarks.

- You can tailor it to what people like nearby – it adjusts easily.

- Production can grow alongside your business – whether you’re small scale or operating on a large level.

- A uniform look across all locations builds a stronger global brand.

Marketing Advantages and Competitive Edge

- Reliable products foster faith, thereby securing customer commitment.

- We build what you need – several products, even those bearing your brand.

- Being kind to the planet boosts how people see your company.

- Markets shift fast, so businesses must adjust swiftly.

- The brand grows because every capsule delivers consistent quality. Or, put another way – reliable capsules fuel growth.