Introduction: The Evolution of Coffee Capsule Production

Over the past ten years, single – serve coffee pods really changed how people everywhere drink coffee – making it easier, more reliable, yet still high-end. It seems simple, yet crafting each capsule involves complex manufacturing – a real effort to lock in flavor and scent. Producers need to grasp the specifics of different brands – Nespresso, Dolce Gusto, Lavazza, Tchibo, for instance – so they can deliver consistent quality alongside global regulations.

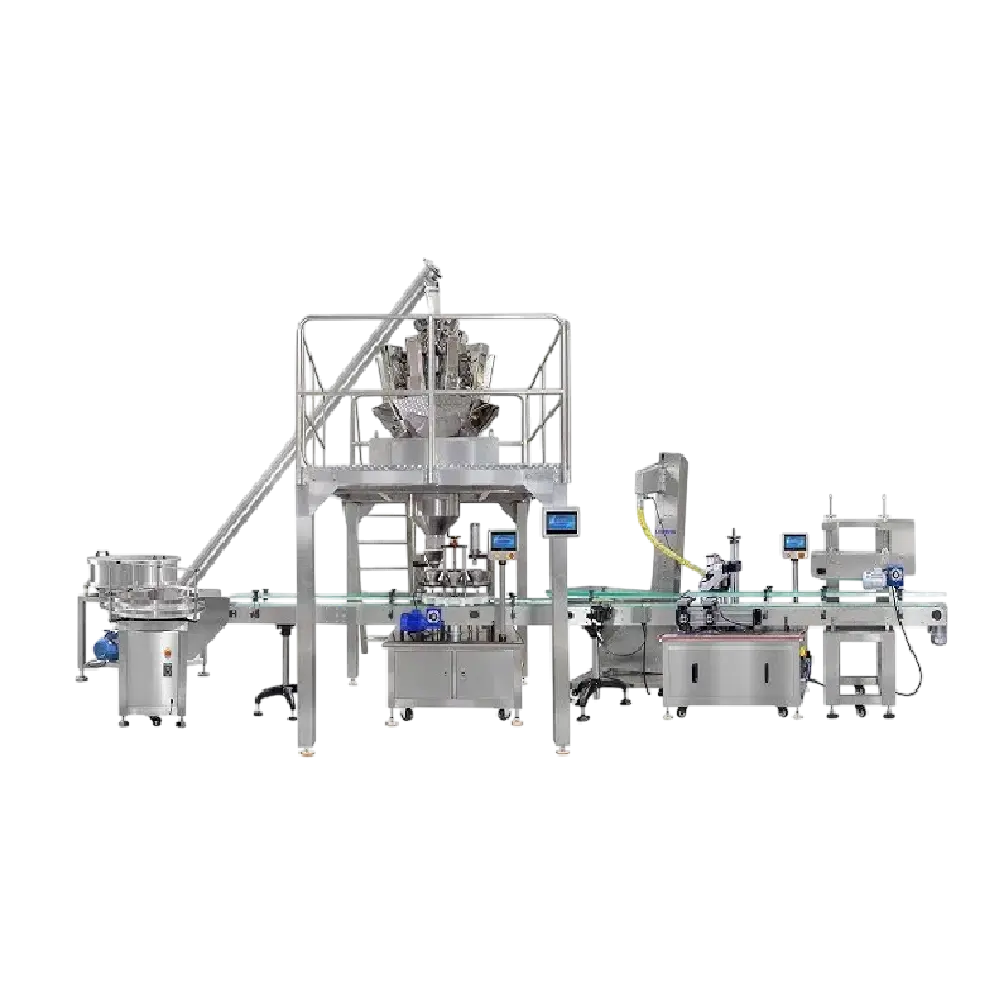

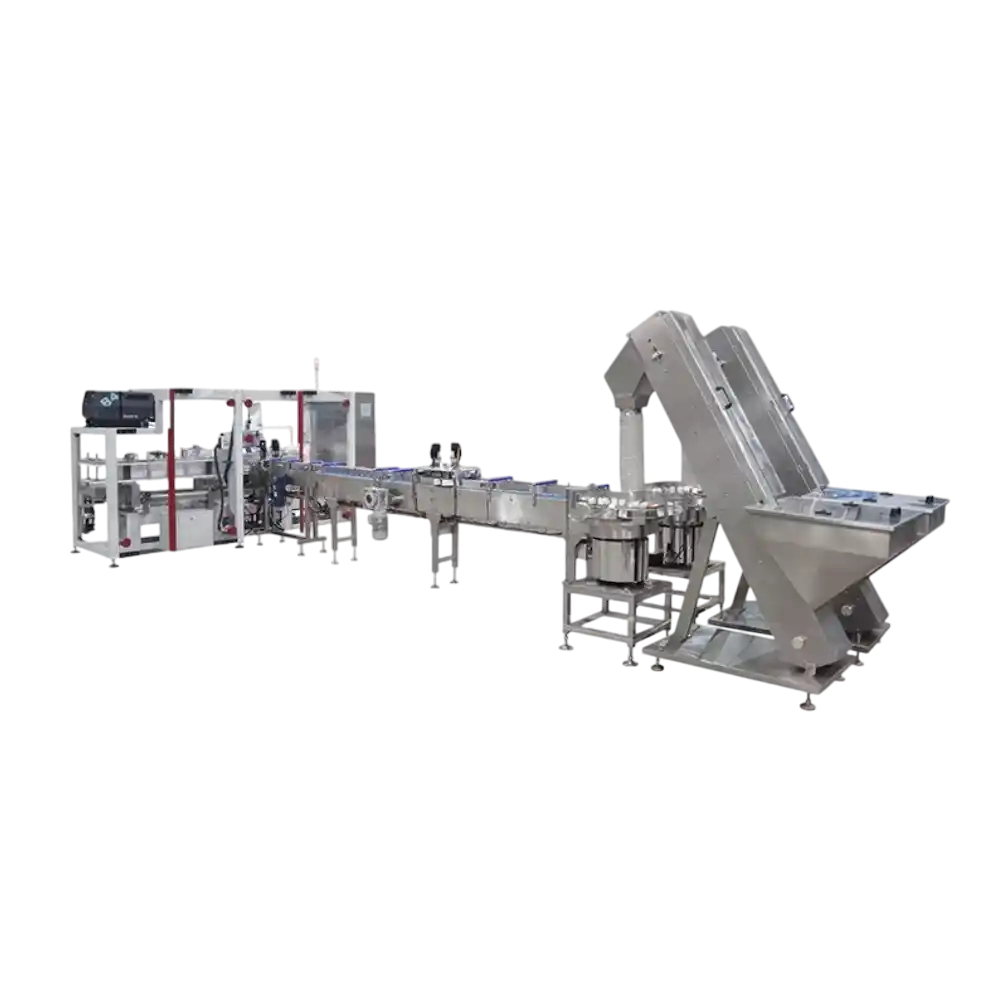

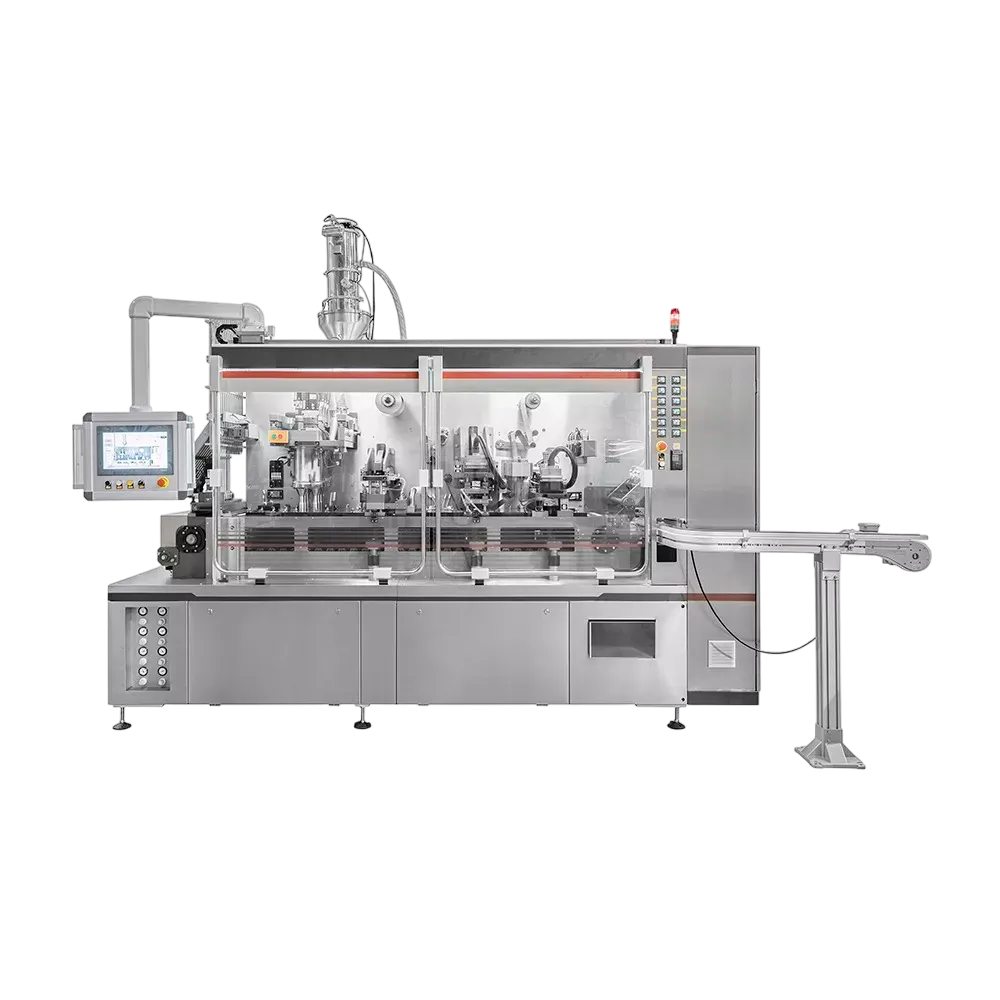

If your business churns out heaps of coffee capsules, the filling machine truly matters. It dictates how precisely each one fills, whether it seals properly, also how fresh the coffee stays. Several makers compete, yet DragonTechMac machines consistently set the standard – they help companies deliver capsules customers demand.

1. Understanding Coffee Capsule Systems

Coffee makers using single servings come in many forms – each needing a unique capsule shape, size, alongside how tightly it’s sealed. Whether it’s Nespresso’s small aluminum containers or bigger Dolce Gusto plastic pods, companies have to adjust equipment so everything works just right.

1.1 Nespresso Coffee Capsules

Across the globe, people favor Nespresso capsules. They’re small, look good with their sleek metal shells, keep coffee fresh because they seal well – a nice mix of how things appear alongside how effectively they work. Making lots of them calls for specialized machines that fill each one accurately, holding to very strict standards.

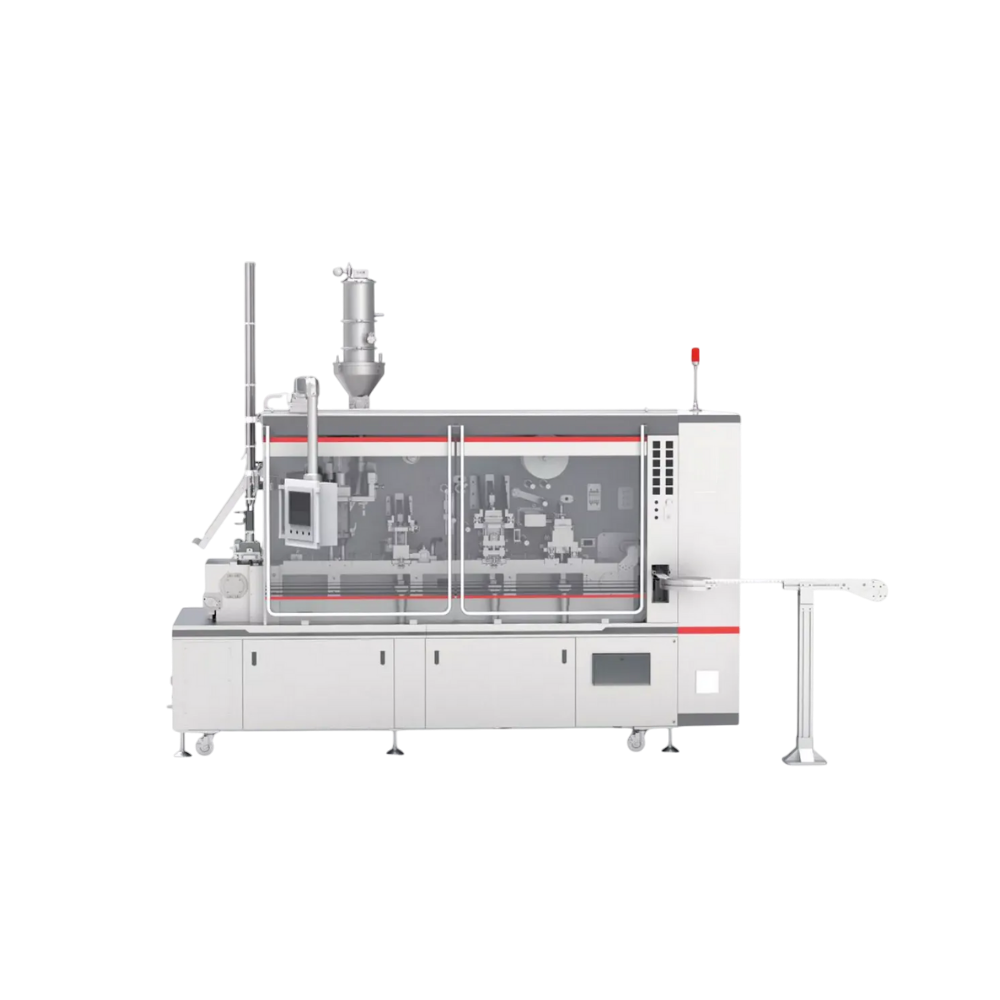

Getting the coffee grounds just right – usually around 5.5 to 6 grams – is tricky, especially when you also need a steady grind alongside firm, even pressing. Small changes really throw off how well the coffee brews. DragonTechMac built a Nespresso capsule filler that delivers spot-on results each time. It fills capsules uniformly, seals them airtight, then prepares them for nitrogen – this keeps the coffee fresh.

DragonTechMac machines lock in coffee’s scent alongside its taste. They do this via careful automation coupled with air removal – keeping oxygen away. Consequently, each pod tastes consistent, regardless if they make a few or many.

1.2 Dolce Gusto Coffee Capsules

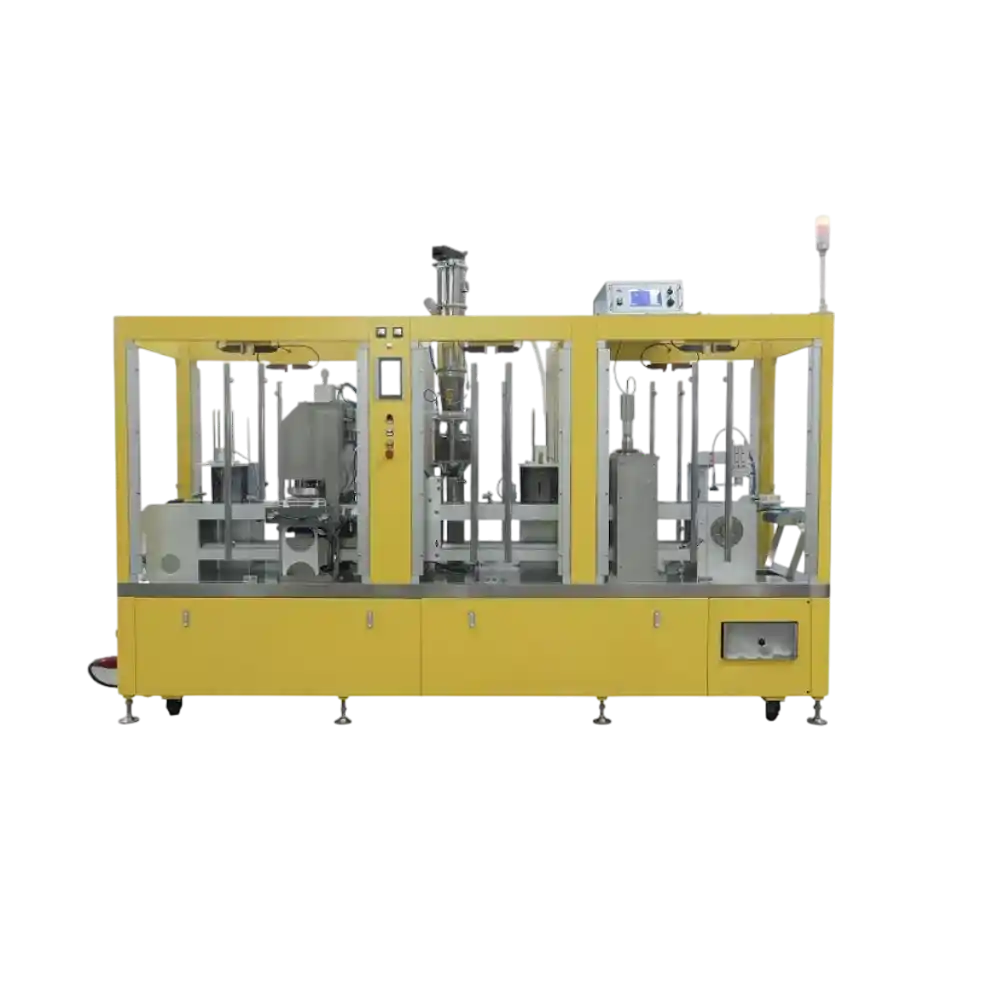

Unlike Nespresso pods, Dolce Gusto capsules usually come in plastic – they’re bigger too. Because they hold more, these capsules work well with milk drinks or even hot cocoa. So, if a factory wants to make different kinds of beverages, a Dolce Gusto capsule filling machine is a smart addition.

To get just the right amount of coffee into those Dolce Gusto pods – whether it’s powdery stuff or bigger bits – the filling has to be spot on. Mess up the fill, or don’t seal them well enough, and you risk spills, weak coffee, or weird tastes. That’s where DragonTechMac comes in; their machine carefully measures each pod while also controlling the heat when it seals, consistently delivering quality.

To help products stay fresher longer, DragonTechMac equipment uses nitrogen plus special packaging layers. Together, these block out air and dampness – so coffee remains flavorful right up to when someone enjoys it. Moreover, the adaptable build lets manufacturers easily switch between diverse capsule types or dimensions, meaning less downtime during changeovers.

1.3 Lavazza Coffee Capsules

Lavazza excels at espresso, offering capsules meant to capture genuine Italian coffee enjoyment. These pods demand exact sizing, proper brewing force, alongside airtight seals – all vital for preserving Lavazza’s rich taste and signature foam. Companies using these capsules rely on specialized machinery crafted to fit their shape also work well with particular packaging.

The DragonTechMac machine fills Lavazza coffee pods using clever sealers alongside heaters you can tweak, making airtight closures on either aluminum or plastic. Getting these settings right protects freshness during transport and storage. Also, its system carefully measures coffee grounds so each pod brews a great shot.

If you run a factory making coffee pods – the kind like Lavazza uses – keeping things running smoothly is vital. DragonTechMac machinery boosts how much you can produce, also minimizes interruptions. Built to last with self-checking features, these machines handle round-the-clock work without issue.

1.4 Tchibo Coffee Capsules

Tchibo capsules stand out thanks to how they look – also how coffee brews inside them. They’re usually crafted from polypropylene, featuring an airtight top that demands careful attention when filled then closed. Consequently, machines built to fill these capsules need real finesse, adapting readily with precise management.

To tackle tricky coffee capsules, DragonTechMac built a machine boasting carefully made parts alongside flexible fillers. It consistently delivers equal amounts of coffee while securely closing each capsule – all without breaking them. A quick nitrogen burst then removes oxygen, keeping the coffee fresh longer.

With a growing focus on protecting our planet, DragonTechMac now helps make capsules that are kinder to the environment. They build machines tailored to work with materials which break down naturally – so companies can comply with upcoming rules while still delivering top-notch products.

2. The Role of Coffee Capsule Filling Machines in Quality Control

2.1 The Importance of Filling Accuracy

For a coffee company to thrive, its flavor must always be reliable. Large manufacturers simply can’t tolerate changes in how their coffee tastes, smells, or brews. That’s where DragonTechMac comes in – their capsule fillers use precise mechanisms alongside automatic weighing to ensure each dose is spot on.

We weigh each gram of coffee carefully so every single capsule brews the same way. Because of this consistency, people come to rely on our product – a big deal when lots of choices are available.

2.2 The Sealing Process: Protecting Freshness and Flavor

Once filled, keeping things sealed is key to maintaining freshness. A poor seal lets in air alongside water, causing flavors to go off. DragonTechMac uses both heat and sonic welding on every machine – whether it’s making Nespresso capsules or Tchibo ones.

Consistent heat alongside firm pressing secures the film onto the capsule edge. Simultaneously, a nitrogen rinse establishes an internal environment within each capsule – sealing scent and keeping contents fresh over time.

2.3 Hygienic Design and Material Handling

Workplaces needing strict cleanliness – think factories – demand top-notch safety. DragonTechMac equipment uses stainless steel suitable for food preparation, built with parts easily taken apart to clean. Its design, featuring sleek forms alongside automated washing features, cuts down on buildup while meeting global rules like those set by CE and ISO.

3. DragonTechMac: Engineering Precision for Coffee Capsule Production

3.1 Why DragonTechMac Machines Stand Out

DragonTechMac now means dependable, inventive solutions for packaging worldwide. Each machine they build – whether it fills Nespresso, Dolce Gusto, Lavazza, or Tchibo capsules – is born from extensive study alongside major coffee companies.

DragonTechMac builds machines with careful crafting, adaptable parts, so they are simple to use. From small runs of ten thousand daily to large ones hitting one hundred thousand, these machines keep things running smoothly while still delivering top-notch capsules.

3.2 Integrated Automation and Control Systems

To make capsules today, things need to run themselves intelligently. DragonTechMac links computer controls alongside simple touch screens so people overseeing the process can follow everything – weighing ingredients, closing them up, then getting ready to ship. Sensors immediately flag any problems, cutting down on scrap plus machine stops.

Manufacturers utilize data logs to understand how things are running, monitor what’s being made, moreover keep detailed records of each product group. Consequently, this automated system guarantees adherence to strict global quality controls.

3.3 Adaptability for Multi-Capsule Production Lines

DragonTechMac really shines because it’s built to be flexible. Manufacturers making different kinds of coffee pods – like those for Nespresso or Dolce Gusto – can shift production without a major overhaul. They simply swap out tools, tweak how much coffee goes in each pod, then adjust the sealer; this means quick adjustments and very little downtime.

Because it bends easily, production can shift with what buyers want – or the market does – keeping expenses down while boosting profits.

4. The Connection Between Machine Quality and Coffee Quality

Good beans go dull when packed wrong. Keeping that rich taste isn’t simply about where coffee comes from; it’s also about careful handling – filling, then sealing. Things like dampness, air pressure, heat, alongside how long each step takes, all play a role.

4.1 Protecting Aroma Through Precision Sealing

DragonTechMac devices employ nitrogen to displace oxygen within capsules prior to sealing. Consequently, flavor stays put – oxidation, typically responsible for staleness, doesn’t happen. Therefore, coffee retains its scent alongside richness over extended periods, delivering a consistently vibrant cup to those who drink it.

4.2 Maintaining Coffee Density and Extraction Performance

How well your coffee brews hinges on evenly spread grounds within the capsule. DragonTechMac machines manage both how much goes in alongside how tightly it’s packed. Consequently, water moves through consistently when you brew, yielding better crema then a more reliable taste.

4.3 Efficient Packaging for Extended Shelf Life

Once sealed, capsules go into secure packaging for extra safety. DragonTechMac provides systems connecting sealing directly to packing – less touching means fewer chances for things to go wrong.

5. Sustainability and the Future of Coffee Capsule Production

Coffee folks are really focused on being greener these days. With more people paying attention, companies need to find ways to help the planet. DragonTechMac pitches in by building equipment that works seamlessly alongside capsules made from stuff you can recycle, let decompose naturally, or even toss on the compost heap.

5.1 Eco-Friendly Capsule Materials

Soon, coffee pods will use more materials from plants instead of plastic – also less aluminum. The people at DragonTechMac collaborate with those who make the materials so Nespresso, Dolce Gusto, Lavazza, and Tchibo pod machines can work with them while still keeping a tight seal.

5.2 Energy-Efficient Machine Design

Saving energy affects your wallet – also, the planet. DragonTechMac builds heaters that don’t waste electricity; they turn on only when needed, yet still work wonderfully.

5.3 Reducing Waste in Production Lines

DragonTechMac spots flaws automatically, adjusting things to cut down on wasted materials and products. It guarantees every capsule is spot-on, so factories streamline operations – boosting profits while being kinder to the planet.

6. Choosing the Right Machine for Your Business

Figuring out which coffee capsule machine suits you hinges on how much you want to make, what kind of capsules you use, also where you plan to sell. Here’s what matters most:

6.1 Production Capacity

DragonTechMac builds machines for any size operation – whether you’re starting small or running a huge factory. They handle capsules for brands like Nespresso, Dolce Gusto, Lavazza, also Tchibo, adapting alongside your company’s expansion.

6.2 Capsule Compatibility

To work right, the machine needs to handle your capsule – whether it’s plastic, aluminum, or breaks down naturally – as well as the covering used to seal it, like foil, a mix of materials, or paper. DragonTechMac builds tools specifically for each capsule shape so everything fits smoothly into how you already make things.

6.3 After-Sales Support and Global Service

DragonTechMac doesn’t just build things; they stand behind them. Should something go wrong, expect readily available replacement components, help from a distance, alongside a worldwide team geared toward swift solutions – keeping interruptions brief while output remains high.

Conclusion: Precision, Quality, and Trust in Every Capsule

To thrive, a company making coffee capsules needs to skillfully blend tech expertise, careful execution, alongside unwavering quality. Regardless if they craft capsules for brands like Nespresso, Dolce Gusto, Lavazza, or Tchibo, choosing a dependable filling machine isn’t merely about operations; it shapes their entire business approach.

Worldwide, companies making coffee for factories rely on DragonTechMac. Their machines fill, seal, then package coffee capsules so each one stays fresh – delivering a great taste to people who brew at home.

DragonTechMac helps factories keep pace with today’s expectations – good products, streamlined work, responsible practices – through clever ideas, solid construction, alongside designs built around what people actually need. When crafting coffee capsules, exactness is key; DragonTechMac doesn’t flinch.