The Impact of Machine Quality on Coffee Freshness, Flavor, and Packaging Efficiency

1. Introduction: The Art of Perfect Coffee Production

These days, great coffee isn’t simply a matter of good beans; it’s also how that coffee moves through processing, gets sealed up, then stays fresh. Each step shapes the flavor, scent, alongside how long it lasts. A flawless brew relies on clever machines safeguarding its goodness – from roasting onward to when it’s ready for your mug.

Dragon Tech excels in crafting equipment for coffee packaging. Leveraging years spent perfecting their designs, they provide robust machines for filling capsules, jars, sticks, moreover boxes – each built to maximize both speed yet maintain superb standards. They guarantee consistent precision alongside preserving the aroma plus taste of coffee throughout distribution.

Folks who make coffee know a good machine means good coffee. Cheap equipment causes uneven amounts, bad seals, then staleness – ruining how customers feel about the brand. But solid machines deliver consistent results, keep coffee fresh longer, thereby building loyalty.

2. Why Machine Quality Matters in Coffee Manufacturing

To please coffee drinkers worldwide, every cup needs to be just like the last – same flavor, same wonderful smell. Getting that right relies heavily on the equipment handling filling then packaging.

Machines that aren’t up to par frequently mean uneven weights, compromised seals, alongside differing amounts of oxygen – all things that hurt how long flavors last. If packaging isn’t properly closed, air or dampness gets in, causing products to go stale sooner. Also, unreliable dispensers either squander product or provide incorrect amounts, creating expensive problems.

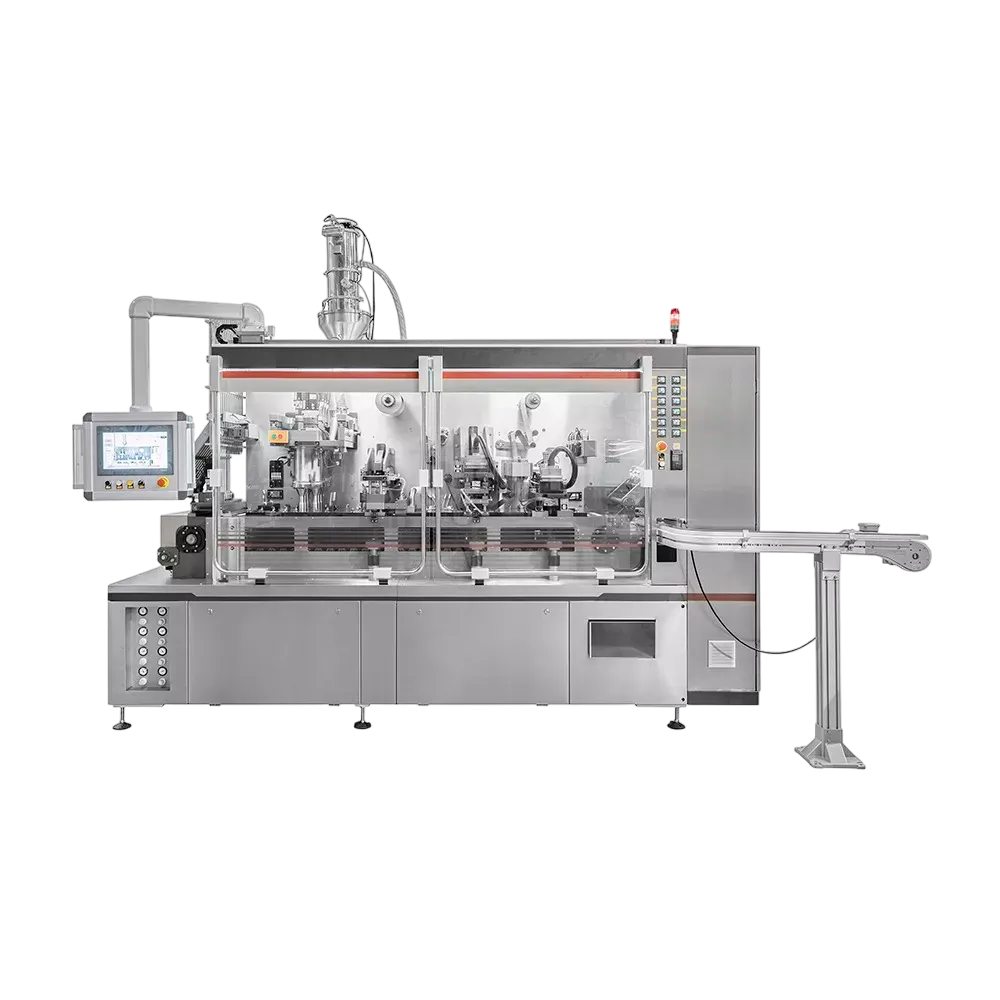

Dragon Tech builds machines designed to sidestep problems. They use stainless steel, precise motors alongside smart controls – guaranteeing steady performance, exactness, then lasting dependability. Consequently, these features cut interruptions, lessen scrap, also confirm each container gets properly filled and closed.

3. How High-Quality Machines Extend Coffee Shelf Life

Coffee readily goes stale when touched by air, brightness, or dampness. These things quickly diminish its taste, smell, alongside how new it feels. Keeping it fresh calls for packaging that truly seals – a solid closure makes all the difference.

Dragon Tech equipment combines air removal alongside nitrogen introduction, purging packages of oxygen prior to closure. Consequently, ground or powdered coffee stays fresher – its aroma and flavor remarkably preserved – for a significantly longer time.

Coffee freshness hinges on keeping air out – even a brief whiff can dull its taste. Dragon Tech machines shield beans throughout filling, then lock in flavor with airtight seals blocking dampness alongside sunlight. Consequently, each cup tastes like freshly roasted perfection.

How products are packaged – be it in tins, bottles, pouches, or cartons – really impacts how long they stay good. Top-notch equipment delivers even seals, steady heat, then accurate timing; these factors keep coffee flavorful.

4. Precision in Coffee Filling and Sealing: Protecting Aroma and Freshness

Folks these days want consistently great coffee. Achieving that requires equipment delivering exact amounts alongside secure closures.

Dragon Tech machines handle varying amounts, keep out dust, seal layers well – working with foil, plastic, even earth-friendly materials. Consequently, products stay fresh alongside green goals.

These devices stop messes – leaks or unwanted stuff getting in – keeping everything clean while they work. Every spot where things get filled has smart detectors that see how much is there, then tweak themselves to be precise, even when working quickly.

Dragon Tech keeps each packet fresh, shielding taste while stopping staleness. It also looks sharp, building confidence with those who buy.

5. The Role of Packaging in Product Presentation and Sales

Coffee packaging isn’t simply about keeping beans safe; it speaks volumes. It showcases what the brand stands for, hints at how good the coffee is, moreover, it shapes whether someone buys it. More than six in ten people size up coffee based on how it’s packaged. Packaging that looks good – clean, sealed, appealing – suggests a fresh, high-end product.

Packaging matters just as much as how the coffee is roasted or ground – even great beans fall flat with bad packaging. Good machines don’t simply shield the product; they deliver accurate branding alongside a pleasing look.

Dragon Tech equipment ensures labels stick just right, runs smoothly with different package dimensions – so brands get a high-end, uniform appearance. From single-serve coffee pods to hotel packets or supermarket jars, better packaging means products stand out more, thus boosting sales.

6. Dragon Tech Machines: Setting a New Standard in Coffee Production

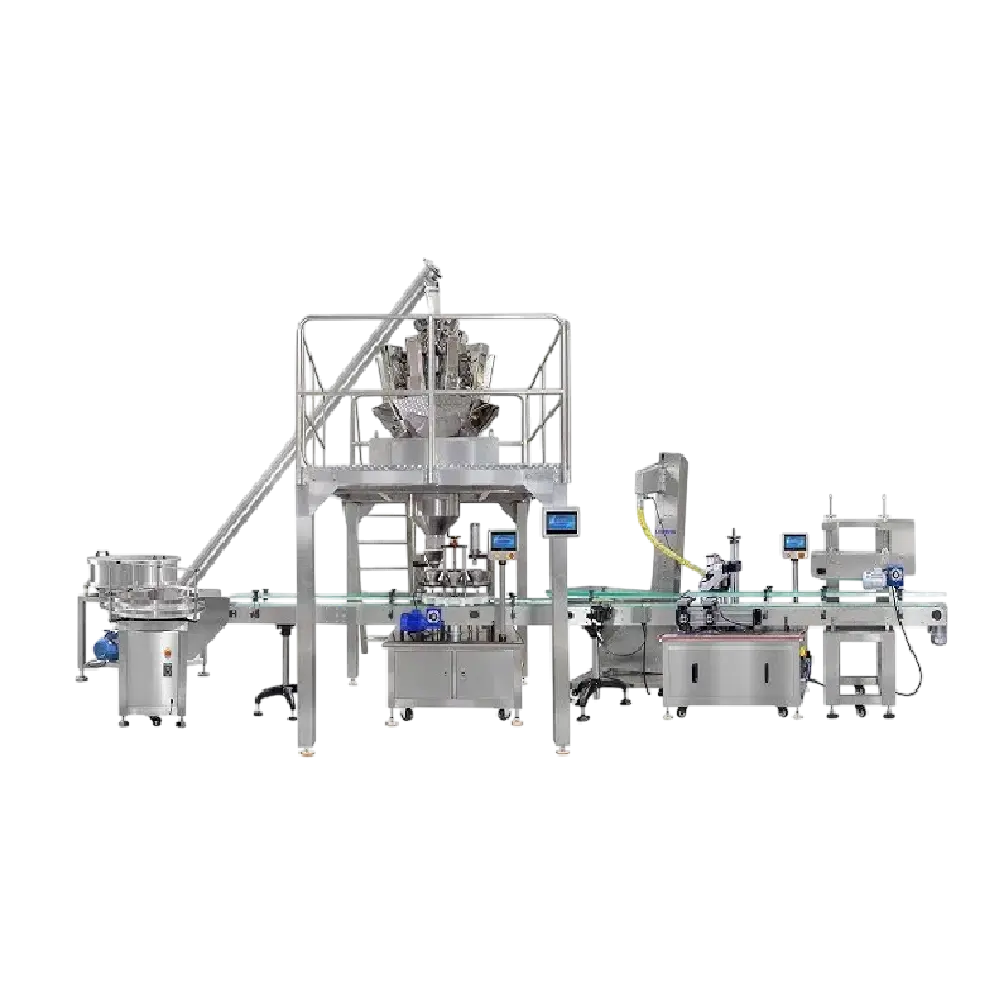

6.1 Coffee Capsule Filling Machines

Dragon Tech builds machines that stuff then seal coffee into different kinds of pods – Nespresso, Dolce Gusto, Lavazza, even K-Cups. They work fast, yet carefully, turning out loads of consistently filled, tightly sealed capsules every sixty minutes.

The DTC Series machines feature:

- A method to keep things fresher longer – it uses nitrogen

- Filling happens precisely because motors steer it – so you get just the right amount

- Choose a method – either ultrasonic welding or heat sealing

- Built in pieces, so fixing things is simple

- A simple touchscreen lets folks easily manage the system

Automation boosts how things get done while cutting down on mistakes – a real win for big manufacturers or smaller coffee companies wanting top-tier performance.

6.2 Coffee Jar Filling Machines

If your business puts ground or instant coffee in jars, Dragon Tech machines fill them cleanly, quickly – completely on their own. Whether you use glass, plastic, or metal, they work just as well.

These devices gather dust while also fighting static, so things don’t stick or leave a mess – keeping both what they make and themselves clean. They seal packages tight using foil or lids, which means contents stay fresh much longer.

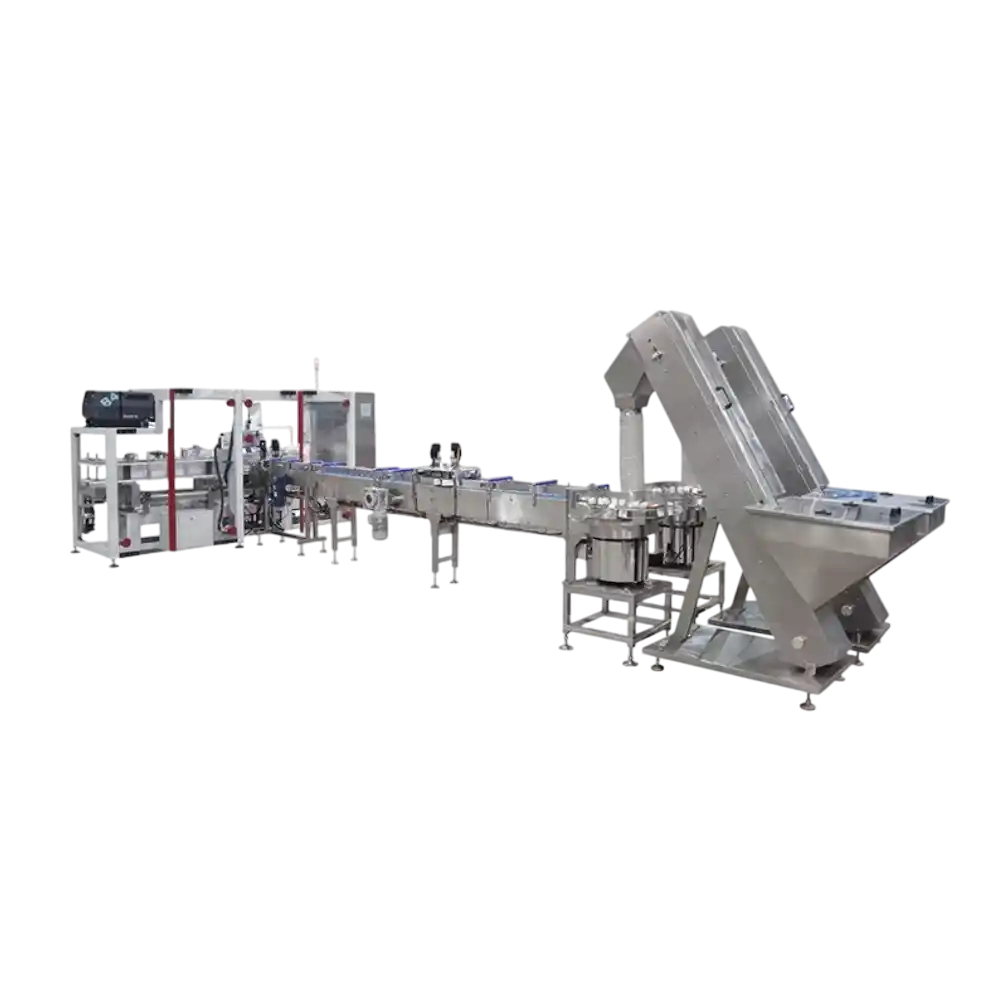

6.3 Coffee Stick Filling Machines

Coffee’s shift toward single cups wouldn’t have happened without those handy sticks – Dragon Tech builds machines that fill and seal them quickly, making sure each one has just the right amount with a solid closure.

The DTS Series stick machines provide:

- Lots of lanes mean things move quickly

- Accurate hole-boring systems deliver material.

- Advanced temperature control

- A motor gently guides film forward

- To keep things from rusting, we bubble nitrogen through it

These devices – whether they craft three-way coffees, quick espressos, or powdered mixes – ensure quality remains high alongside happy customers.

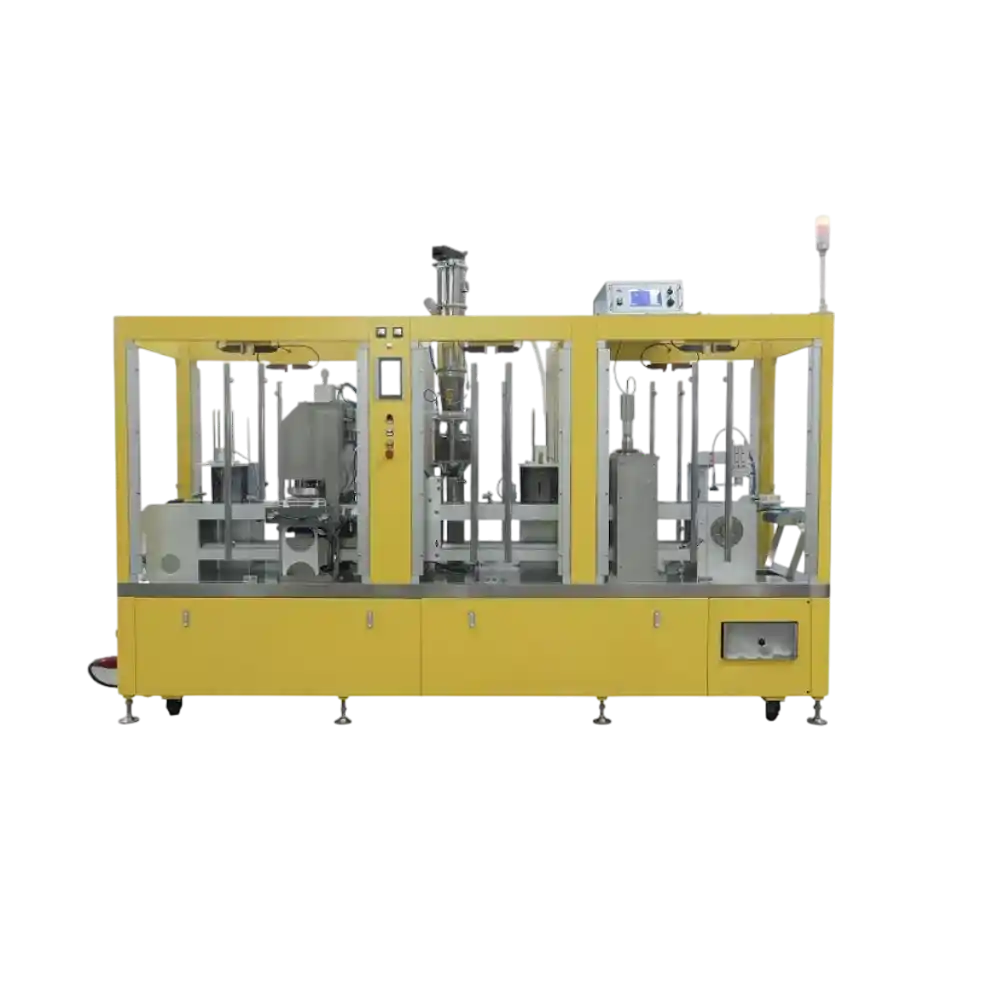

6.4 Coffee Box Packaging Machines

Dragon Tech packs products into boxes – not just bottles, tubs, or pouches – for quick shipping to stores. The machines fill, close, then stick labels on boxes tailored to any size needed, working well for online orders also when sending goods abroad.

A solid build alongside smart controls means quicker packing – still reliable. Consequently, coffee companies can grow smoothly, never compromising taste.

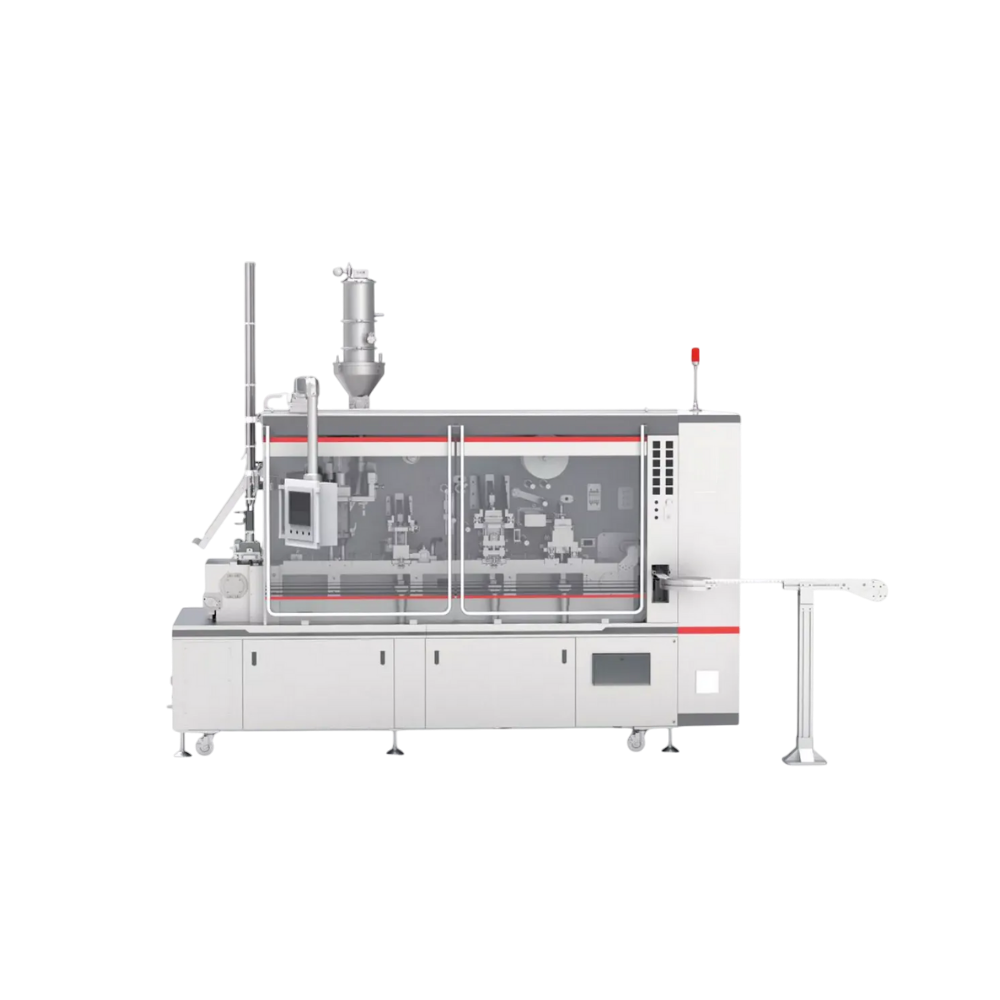

7. Durability and Energy Efficiency: The Hidden Strength of Dragon Tech

Thinking about a coffee packaging machine? It needs to last, also work well. Dragon Tech builds theirs tough – designed to run constantly in factories – using quality parts from leaders like Siemens, Mitsubishi, yet Schneider.

Before leaving our facility, every machine gets thoroughly checked for quality – we want them to work flawlessly for a long time. Built with stainless steel, they resist rust, wipe down quickly, moreover meet global food safety rules.

Dragon Tech builds machines that don’t gulp energy. They cut down on air use, refine how motors work, also trim scrap – meaning less money spent and a lighter footprint on the planet. It’s about getting strong results without costing Earth too much.

8. Automation, Technology, and Consistency in Coffee Production

Coffee’s tomorrow hinges on machines. Old ways of doing things simply won’t cut it given how much coffee the world now wants. Systems from companies such as Dragon Tech deliver consistency, cleanliness, alongside accuracy.

Smart systems oversee everything – adjusting settings, tracking progress instantly. This keeps production moving smoothly. Because these systems use data, mistakes happen less often, meaning better products arrive faster.

Dragon Tech equipment doesn’t just build things; it protects what matters. It combines careful looks, a gas rinse, then airtight packaging so taste, smell, and freshness stay locked in – consistently.

9. Why Businesses Trust Dragon Tech for Long-Term Productivity

Globally, numerous companies depend on Dragon Tech because its equipment simply works consistently. These machines withstand heavy use; moreover, they come with complete assistance – from setup to expert instruction.

Dragon Tech’s after-sales service includes:

- Fixing issues from afar, offering help through live video

- On-site installation support

- Spare parts availability

- Lifetime technical consultation

Clients benefit from steady output because these offerings keep systems running smoothly, curtailing halts to manufacturing while upholding dependable standards.

Growing a coffee company? Dragon Tech doesn’t just sell equipment; they become your ally, bringing fresh ideas alongside steadfast support.

10. Conclusion: Quality Machines, Quality Coffee

To thrive in today’s coffee market, good machines aren’t optional – they’re essential. Whether keeping flavors fresh, lengthening product lifespan, or making beans look their best, each step relies on dependable equipment.

Dragon Tech still sets the standard for equipment that fills coffee capsules, jars, sticks – also boxes everything expertly. These robust machines deliver pinpoint accuracy alongside streamlined performance; they redefine how pros make coffee.

Dragon Tech doesn’t merely sell machines; it fuels a lasting, superior coffee business for you.