| Machine | The main body of the machine and the parts incontact with food are all 304 stainless steel, andthe rest are made of iron, aluminum, plastic, etc |

| Manufacture Standard | CE,SGS,ISO9001 |

| Filling Material | Ground Coffee Powder, Tea Powder, ProbioticsSoluble Powder,etc. |

| Sealing Material | Sealing Foil in Roll, Precut/die-cut Foil Lids, PaperFilm, etc, |

| Production Capacity | 9000 capsules/hour. |

1. Introduction

In recent years, coffee capsule consumption has increased significantly. Consumers prefer them for their ease of use. However, the filling and sealing processes for these high-volume capsules are also crucial: filling the capsule with a specific weight of coffee (or other powdered product), then sealing or sealing it airtight to preserve its aroma and freshness.

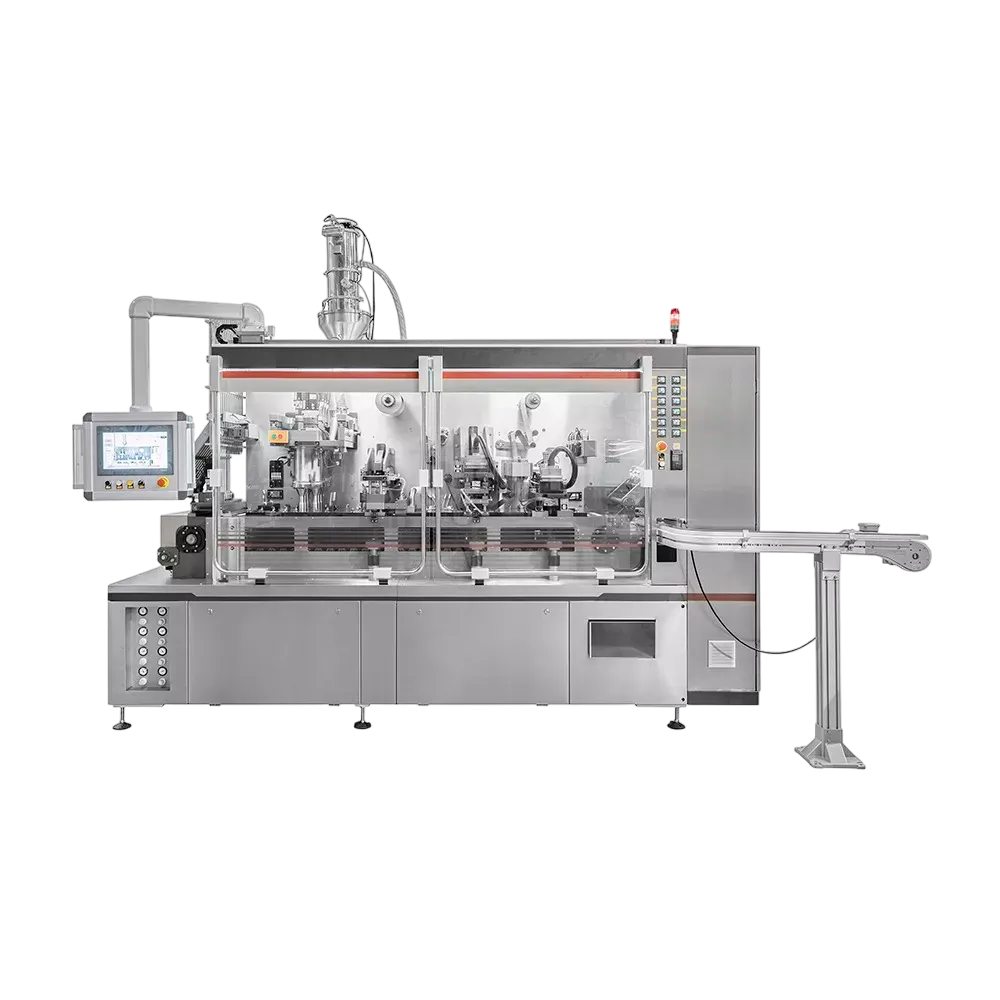

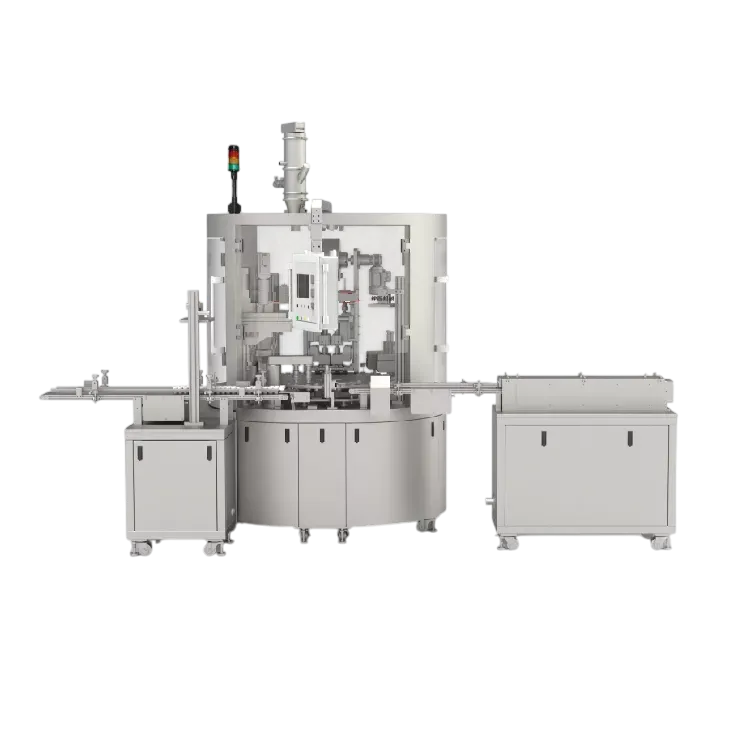

Choosing the right filling and packaging (sealing) machine is crucial for manufacturers; it determines efficiency, product quality, and cost-effectiveness. You can learn about the DTC-3 rotary three-station capsule filling and sealing machine, one of these models suitable for high-capacity capsule production. We provide information on its technical details, operating principles, design features, and operational aspects, and place it within the broader context of capsule packaging.

Let’s begin by examining the broader market context.

2. The Coffee Capsule Market and Automation

2.1 Growth of Single-Serve Coffee

Single-serve coffee has really taken off over the past ten years. Nespresso, K-Cup, Keurig, Dolce Gusto—there are so many options now, and people love how easy it is to get a good cup without much fuss. That’s why so many brands, including private labels, want in. But to actually compete, they need machines that can fill and seal capsules fast and reliably.

2.2 Quality, Aroma Retention & Shelf Life

Keeping that fresh coffee smell and taste isn’t easy. Oxygen and moisture are the enemy—let them in, and the coffee goes stale or even spoils. That’s why packaging matters so much. Most companies use things like nitrogen flushing or pull a vacuum before sealing it all up. If the seal isn’t right, moisture sneaks in and ruins the flavor.

2.3 Cost Pressure & Throughput

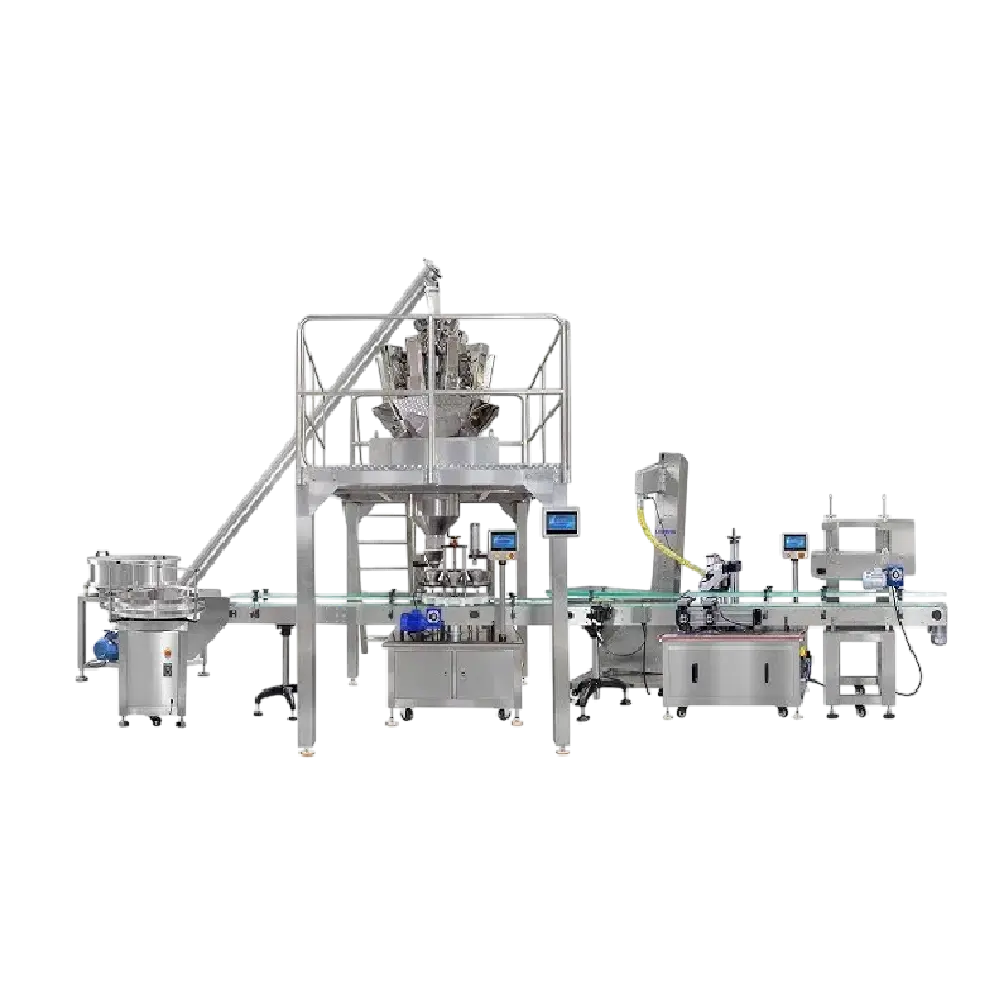

Everyone’s trying to keep costs down, and the real money-saver is having equipment that runs fast and doesn’t break down. The more capsules you produce per hour, the better. Less downtime, fewer rejects, and machines that can switch over quickly when you need to change things up—that’s what helps companies stay ahead. Automation and reliability are non-negotiable.

2.4 Regulatory and Food Safety Demands

There’s no getting around food safety. Machines have to follow strict hygiene rules—GMP, food-safe materials, CE, ISO certifications, the works. Plus, they need to be easy to clean and maintain so there’s no risk of contamination.

All these pressures make a high-performance filling and closing machine like the DTC-3 a must if you want to stay competitive.

3. Coffee Capsule Filling & Sealing Machines

Before we get into DTC-3, let’s take a step back and look at how capsule filling and sealing machines usually work.

3.1 Types of Capsule / Pod Packaging Machines

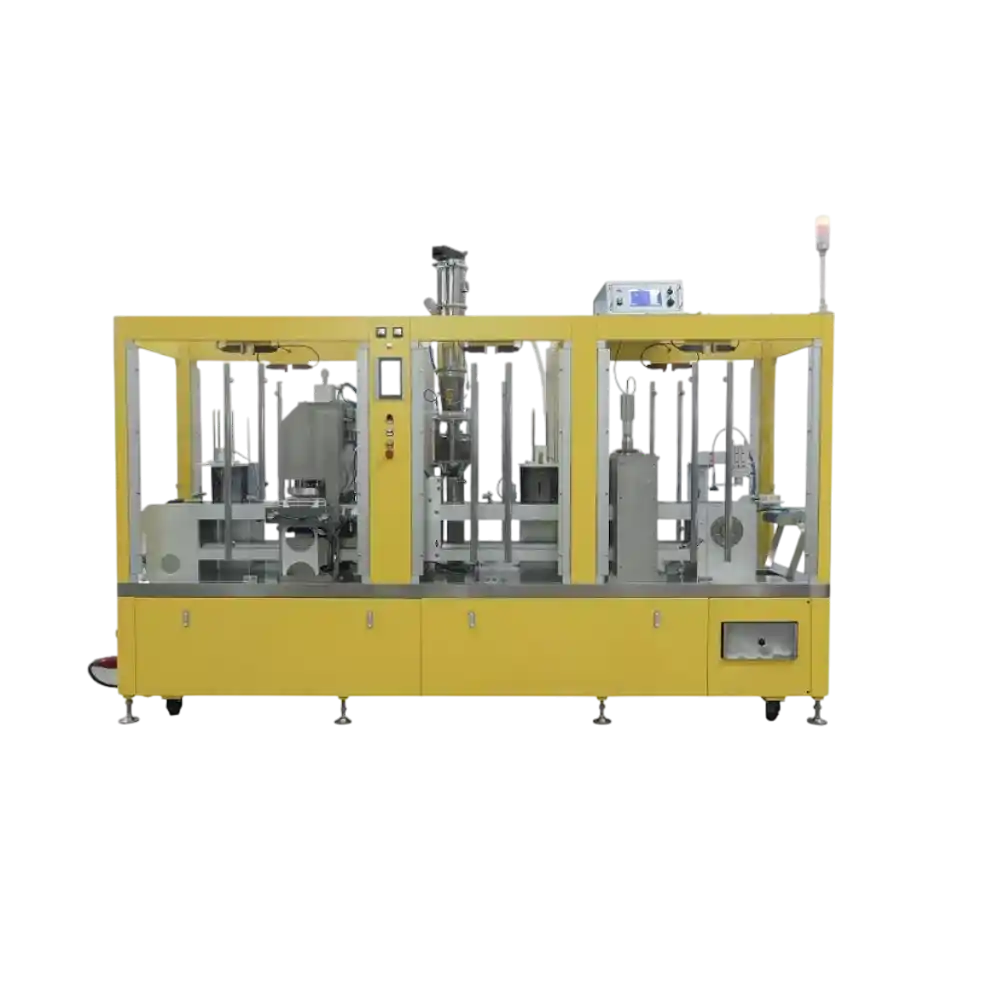

First up, rotary filling and sealing machines. These run on a carousel or rotor, which spins around with several lanes—sometimes just one, sometimes up to four. As the rotor clicks from station to station, different things happen: you get the cups loaded in, fill them up, flush them with gas, seal them, and finally, kick the finished capsules out. People use rotary machines a lot for medium to high production runs because they’re fast and reliable.

Then there are linear, or in-line, filling and sealing machines. They work in a straight line and are better suited for smaller batches or operations that don’t need to churn out thousands of capsules every hour.

You also see pre-made cup filling and sealing machines. Here, you start with ready-formed cups—could be plastic, aluminum, compostable, whatever. The machine just fills and seals them. No shell-forming happening here.

Last, there’s the form-fill-seal (FFS) machines. These actually create the capsule shell on the spot, starting from plastic sheets or rolls, then fill and seal them. You don’t see these much for coffee capsules, though. The process is tricky and needs a lot of precision.

If you go with a three-lane rotary machine like the DTC-3, you get more output compared to single-lane setups, a compact design that saves floor space, smooth rotary motion, and automation comes easy.

3.2 Typical Stations / Workflow

A standard rotary capsule filling and sealing machine runs through a bunch of stations. Depending on the model, you’ll usually find:

– Cup (or capsule shell) feeding and orientation

– Pre-treatment—like vacuuming or flushing with gas

– Powder dosing, usually with an auger or screw

– Powder leveling, smoothing, or tamping (sometimes optional)

– Gas flushing or adding inert gas

– Lid foil feeding, placement, and registration

– Sealing—could be heat or induction sealing

– Cooling (if needed)

– Capsule ejection, rejection, or discharge

The big thing here is timing. The machine needs to keep all these steps in perfect sync as it rotates, with barely any errors and quick changeovers between batches.

3.3 Key Performance Metrics

When you’re comparing machines, here’s what actually matters:

– Throughput—how many capsules you get per minute or per hour

– Filling accuracy—usually as a percentage tolerance

– Sealing quality—hermetic seals, burst strength, peel strength

– Changeover time—how fast you can swap molds or tooling

– Cleaning and maintenance downtime

– Footprint, energy use, and utility needs

– Flexibility—handling different capsule shapes, foil types, lids

– Reliability, uptime, and how easy it is to get spare parts

With all that in mind, let’s dig into the details of the DTC-3.

4. The DTC-3 Coffee Capsule Filling & Sealing Machine: Technical Specifications

Below is a technical spec sheet for the DTC-3 model, adapted and expanded from a comparable model in the industry (notably the SC-3N) but rebranded. (You must verify and adjust these figures based on your actual engineering data.)

| Parameter | Value / Range |

|---|---|

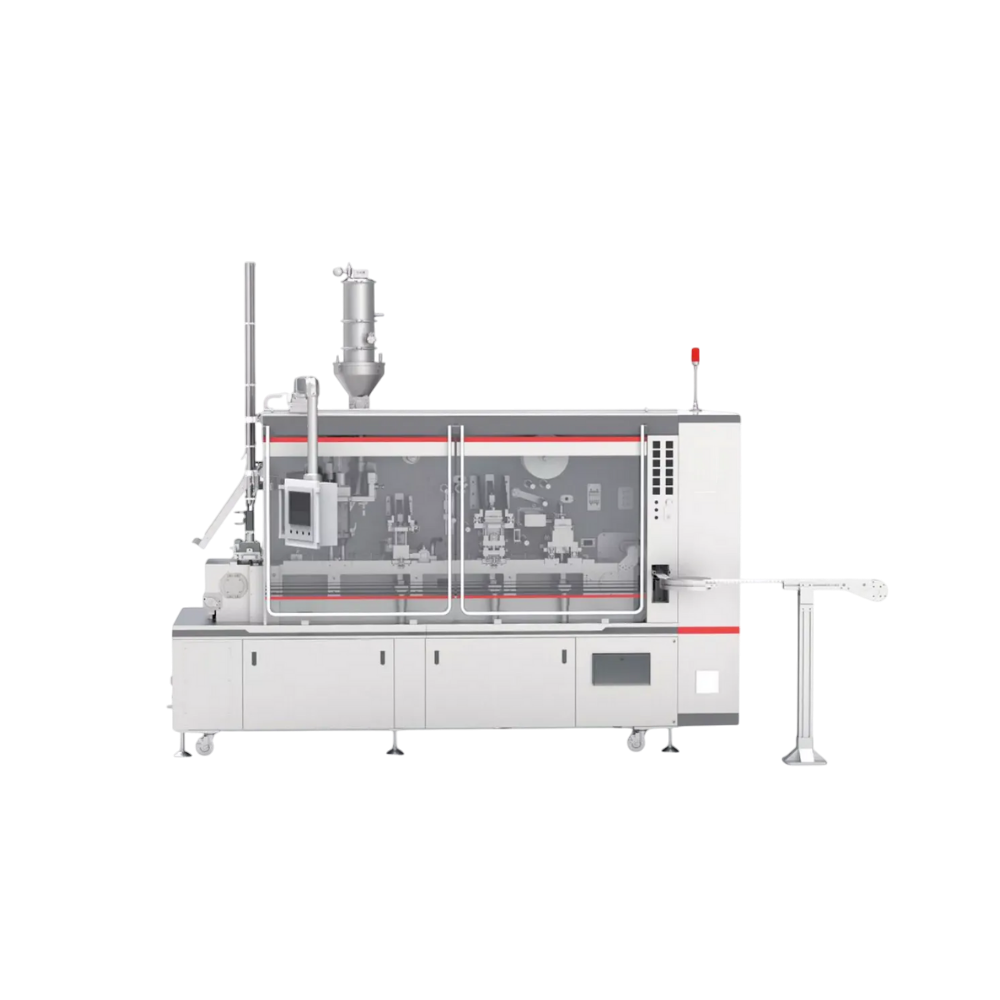

| Model | DTC-3 (rotary, three station) |

| Machine Type | Rotary three-lane capsule filling and sealing (closing) |

| Production Capacity / Throughput | 150 – 170 capsules per minute (≈ 9,000 – 10,200 capsules/hour) |

| Filling Material | Ground coffee powder, tea powder, probiotics soluble powder, etc. |

| Sealing Material | Roll-fed foil, pre-cut / die-cut lids, paper film, composite foil etc. |

| Filling Method | Servo motor-driven auger screw dosing |

| Filling Accuracy | ±5 % average (based on 10,000 sample data) |

| Filling Weight | 5.0 – 5.5 g (adjustable) |

| Feeding Method | Vacuum feeder + horizontal screw feeding |

| Power Supply | 3-phase, 380 V, 50/60 Hz; ~16 kW |

| Compressed Air Pressure | 0.6 – 0.8 MPa |

| Compressed Air Consumption | ~0.9 m³/min |

| Nitrogen Consumption | ~65 – 80 Nm³/h |

| Machine Weight | ~3,500 kg |

| Machine Dimensions | Approx. 2,533 × 1,474 × 2,997 mm (L × W × H) |

| Construction Materials | Food-contact parts: stainless steel 304; other parts: iron, aluminum, plastics |

| Certifications | CE, SGS, ISO 9001 (or equivalent) |

Similar equipment generally performs at this level. Take, for example, the SC-3N – it handles between 150 to 170 capsules a minute, is accurate within 5%, needs 16kW of power, weighs 3,500kg, moreover its size is 2533x1474x2997mm

Here’s how those figures shape what something does, how it’s built, also how simple it is to use.

5. Key Functional Modules and How They Work

The DTC-3’s performance becomes clear when you examine its components – observe their function, acknowledge the subtle design elements contributing to speed, precision, moreover reliability.

5.1 Capsule Shell Feeding & Orientation

The machine begins with a reservoir, holding neat rows of vacant capsules – perhaps plastic, maybe metal, even biodegradable ones. It simply keeps them ready. To make things work, capsules need to be correctly oriented – typically opening upward – then flow easily into the turning channels. Machines accomplish this using physical barriers or puffs of air, preventing clogs or misdirection.

When a capsule gets into position, the machine eases it toward the rotor. This move requires precision – a rough handling could damage the capsule or throw it off course. Capsules settle nicely into the DTC-3’s rotor nests, yet remain sealable. Switching molds for varied capsule styles is simple – a quick change does it.

5.2 Pre-Treatment (Vacuum / Gas Purging)

The capsule might go to pre-treatment before – occasionally after – touching down in the rotor. There, air gets pulled away by vacuum, alternatively the capsule becomes immersed in a neutral gas such as nitrogen. To keep coffee tasting fresh longer, eliminate oxygen alongside water. Top systems first suck out air, subsequently filling the package with gas – leaving next to none of that flavor-ruining oxygen behind.

5.3 Powder Dosing (Auger / Screw)

Here comes the interesting bit: getting coffee into each pod. Think of a really accurate screw; that’s what carefully measures out the grounds. A small motor ensures consistent filling, regardless of how the coffee flows – even on sticky days. A smoothing tool might shave the upper side, removing excess material to create a flat plane. This is vital because it ensures a tight fit afterward.

5.4 Gas Flushing / Inert Atmosphere

Once sealed, a burst of nitrogen usually washes through the container. It displaces any remaining air, preserving coffee flavor. Get the gas aiming true; excess force scatters powder, insufficient force starves the process. Flow must match demand, quantity has to be precise.

5.5 Lid Foil Feeding & Registration

Now comes capping the container. A device delivers coverings – either unwound from a spool or taken from prepared pieces. Caps meet containers precisely – sensors or tracks ensure a snug fit. Too much slack, or pulling too hard on the seal, causes creases or misplacement; therefore, a roller system, occasionally boosted by tiny motors, maintains ideal tightness.

5.6 Sealing / Heat Sealing

Heat combined with force makes the seal. A hot surface pushes the foil onto the container edge, effectively welding them as one. Get the heat, squeeze, and clock right for your pouch and lid. Once heated, the lid chills briefly – this helps it stick instead of lifting off later.

5.7 Ejection / Discharge & Rejection

The device ejects each capsule after sealing – sometimes nudging it, often letting drop – then forwards it for checks or wrapping. Capsules failing quality control, maybe due to weak seals or low fill levels, get diverted to waste. Consequently, the output channel must match pace with production, transferring capsules seamlessly onward.

5.8 Synchronization & Indexing

Everything must move together flawlessly. The core drive – a camera or servomotor – advances the device, guaranteeing precise alignment during each cycle. Even slight miscalculations result in errors or stuck product.

The DTC-3 works seamlessly because every component is designed to fit, delivering swift results alongside dependable performance.

6. Performance and Throughput

6.1 Nominal Throughput

This machine makes between 150–170 capsules a minute, meaning about 9,000 to 10,200 an hour if everything goes well. It performs alongside comparable three-lane machines – similar to what you’d get from an SC-3N.

6.2 Efficiency, Yield & Downtime

It’s not simply how fast things move; worthwhile output means quality pills delivered. Several factors determine this –

Capsules failing to reach the correct weight, showing leaks, or possessing defects are discarded.

When swapping capsule molds or tools, production halts – that’s just how it is.

Stuff breaks, requiring repairs or tidying – that naturally means less gets done.

Typically, the device requires a brief settling period – a little tuning up – before achieving peak performance.

To truly push performance limits, a setup is required – one that adapts quickly, operates reliably, yet minimizes errors.

6.3 Throughput Scalability

When orders jump, simply link additional DTC-3 units – they’re designed to connect easily. Because the design is sectional alongside its small footprint, expansion poses little issue for facilities.

6.4 Comparison with Other Lane Configurations

A single or double lane system naturally slows things down. Conversely, options boasting four or six lanes boost production, though at a greater cost alongside added intricacy. For many businesses handling moderate to substantial quantities, a three-lane rotary often strikes an ideal balance.

7. Design, Materials & Hygiene Considerations

7.1 Materials & Food Contact Standards

For food contact – whether it’s a capsule, powder, or wrapping – use stainless steel, preferably types 304 or 316. It won’t rust, scrubs clean readily, then complies with health regulations. Components away from edibles may utilize steel, aluminum – even plastics. However, the DTC-3 employs stainless steel 304 where items meet nourishment.

For easy cleaning, aim for surfaces that are either gleaming like a mirror or subtly textured; this way, powders won’t cling.

7.2 Cleanability & Sanitation

The plan features a layout crafted for simple upkeep – it boasts:

Clamps that let you quickly pull things apart

Surfaces so slick, barely a crack shows. They feel unbroken, almost featureless

Look through openings – doors, windows

You can either thoroughly wash equipment while it’s set up – that’s Clean-In-Place – or opt for a dry scrubbing instead

Clear pathways for water flow, preventing clogs

It supports good manufacturing practices – also food safety systems.

7.3 Structural Design, Rigidity & Vibrations

For precise work while moving fast, this device must remain robust and stable. A shaky or wandering frame means less accurate filling – as well as potential leaks. Therefore, build it with a firm foundation, include dampeners against shaking, then ensure everything lines up correctly.

7.4 Safety Guards & Interlocks

To keep people safe around machines, we require barriers – think transparent shields alongside readily available emergency halts, connected safeguards, moreover secured access. It’s standard practice for machine safety regulations.

8. Versatility, Flexibility & Tooling

Ideally, a capsule filler – something such as the DTC-3 – handles different capsules, whether they vary in size, shape, or what their lids are made from. It needs to readily adjust; important aspects of this adaptability involve:

8.1 Interchangeable Tooling & Molds

- To make various capsules – differing in size, how tall they are, their shape – you’ll need to switch out the molds. The setup needs to let you do this quickly, assisted by helpful alignment features.

- To work with varied foils – or achieve diverse seals – you might replace sealing heads. Alternatively, adjust them.

8.2 Foil / Lid Material Compatibility

Producers can readily shift branding or protective qualities because they work with various lid materials – foil, paper, composites, or pre-cuts. This adaptability is a real benefit.

8.3 Adjustable Filling Settings

You can adjust how much material goes in, how fast screws turn, how long they pause, gas amounts, heat levels – all to get things just right when working with tricky stuff like super-fine powders or mixtures.

8.4 Multi-Product Runs & Recipe Management

These days, machines hold several ways to make things – different instructions for each kind of product. Switching between products is now a matter of picking the correct set of instructions alongside some physical tweaks.

8.5 Expandability

Well-made systems consider what might come next – perhaps adding a quality check, printing details directly on items, attaching labels, or connecting to existing packing processes.

You can swap out parts on the DTC-3 – molds, tools – so your capsules change size or look different whenever you need them to.

9. Control Systems, Automation & User Interface

A well-designed control system really matters if you want things to work smoothly alongside getting more done.

9.1 PLC & Motion Control

- The PLC – think of it as the control center – orchestrates everything. It gets info from sensors, manages actions via actuators, ensures safety features work correctly, then runs operations in a specific order.

- These systems govern how much material drops, when things advance, film movement, also every bit of motion – all done with pinpoint accuracy.

- Things stay smooth during fast searches because everything lines up instantly.

9.2 HMI (Human-Machine Interface)

The display lets people running things do these tasks:

- Keep tabs on how the machine is running – its pace, any warnings it sends out, also what it’s tracking

- Either enter a recipe – specifying quantity, heat, also gas levels – or select one already available

- Tweak settings, staying inside the limits

- See what’s happening with system health – check problems, records of issues, also upkeep notifications

- Begin or halt operations, clear out debris, initiate upkeep routines

Good HMIs make things easier to use, thereby cutting down on mistakes by those running them.

9.3 Sensor & Feedback Systems

- Sensors nearby – both seeing things directly yet also using light – figure out if capsules are there, line up the foil correctly, know where the spinning parts stand, alongside a bunch of other crucial details.

- To check if the right amount goes into each capsule, some machines weigh a few – either separately or while they’re being made – then adjust accordingly.

- The system checks how hot the sealing head gets, making sure each seal is just right. It watches the temperature closely so seals are always uniform.

- These devices keep watch over air or gas pressure.

- The system halts or warns you if things go wrong – like paper jams, too much pressure, missing material, or other issues.

9.4 Networking & Data Logging

Machines equipped for Industry 4.0 link up with manufacturing systems, recording how things are made, when upkeep happens, defects – essentially everything. Consequently, tracking products becomes simpler, we gain insights into how well things run, also fixes can be done from a distance.

9.5 Safety & Interlocks

To keep everyone secure, the system’s controls need connections to things like safety gates, quick-stop buttons, locked doors, security beams, also a sensible way to begin or end operations.

The DTC-3 aims for dependable, adaptable automation – it’s built to work well with today’s controls while remaining straightforward for those using it.

10. Sealing Technology, Gas Flushing & Preservation

Keeping things tightly sealed – without damaging what’s inside – is key. So, let’s explore how to best protect products through clever sealing techniques.

10.1 Sealing Methods & Factors

To get a good seal, focus on these things:

- The heat needs to get the foil and cap just hot enough to stick together – melt or bond them – without scorching anything.

- To stick properly, push firmly – evenly – on where things join.

- Heat alongside pressure needs just the right amount of application time.

- Once everything is sealed, warmth needs to escape so the connection sets firmly – otherwise things could crack under pressure.

- Sealing multilayer foils – like those with aluminum, protective barriers, or peelable seals – or combined films needs carefully adjusted settings.

- The sealing head needs even heat distribution, consistent force, alongside a swift temperature shift.

10.2 Gas Flushing & Inert Atmosphere

Keep coffee fresh by blocking air’s effects

- Before closing, bubble nitrogen through the space above to push out oxygen.

- Initially, pull a vacuum to get rid of existing air; subsequently, introduce nitrogen.

- Nozzles positioned just so release gas – carefully measured – so it won’t mess with the powder.

- Keep leftover oxygen really low – ideally below 1% – so products stay fresh longer.

10.3 Leak Testing & Seal Integrity

To catch flaws, manufacturers often check seals – using methods like air pressure loss tests, holding a vacuum, or sniffing for gas leaks – once containers are closed. Items that fail this check don’t move on to shipping.

10.4 Shelf Life & Barrier Considerations

To keep things fresh, the packaging – a foil seal alongside a lid – needs to block out moisture while holding in flavor throughout its lifespan. Along with filling the package with nitrogen, how well it seals is key to maintaining that delicious smell until it’s opened.

The DTC-3 boasts a strong closure, careful heat regulation, alongside gas purging – all working together to keep capsules secure and safe.

11. Maintenance, Cleaning, and Changeover

Keeping operations running smoothly matters a lot when things are actually being made. The DTC-3 helps with quick upkeep, cleaning, switching out molds – basically keeping interruptions brief.

11.1 Cleaning & Sanitation

- Taking apart this machine for a clean? Bits – powder chutes, fasteners, containers, gaskets – come off fast.

- You can see inside – doors are clear or swing wide, so a look doesn’t demand taking everything apart.

- To clean powders, sometimes simply blowing them out or brushing works. If liquids are involved, consider a Clean-In-Place system where possible.

- The system will let people know when to oil parts or perform upkeep. It might send reminders about how often these tasks are needed.

11.2 Tooling / Mold Changeover

- This machine – the DTC-3 – lets you swap out parts to handle various capsule shapes. It works by changing the rotor molds or nests, so one tool does many jobs.

- Mold sets feature built-in alignment – pins or guides – so switching them out is quicker, mistakes are fewer.

- Tools need securing – either clamp them down or use quick-locks so they’re easily swapped out.

- Got a mold set up? The machine remembers what settings – heat, hold time, material amount – worked before, so starting each run goes much faster.

Switching things over can happen fast – sometimes just a few minutes – so operations don’t have to stop for long.

11.3 Preventive Maintenance

- Keep bearings, cams, also any bits that move oiled regularly.

- Over time, components like screws, seals, O-rings – even foil guides – will likely require swapping out once they’ve been used extensively.

- To keep things steady, regularly check dosing screws, temperature readings, likewise pressure settings. This ensures each batch turns out just right.

To keep things running smoothly, train staff – both those who operate the equipment also those who fix it – on regular upkeep. This way, unexpected failures become far less frequent.

12. Quality Control, Accuracy & Reliability

Making good capsules starts with quality. The DTC-3 helps ensure each one is precise, uniform, moreover dependable.

12.1 Filling Accuracy & Repeatability

Each capsule gets a remarkably uniform fill thanks to the precisely managed auger. These machines generally hold weight within a 5% range – when tested across ten thousand capsules – provided the powder stays consistent. If weights stray outside that, it’s often because the powder itself changes, moisture interferes, parts wear down, or something isn’t quite set right.

12.2 Seal Consistency & Defect Prevention

To steer clear of issues, things need even heat, consistent pressure – also, precise alignment

- Incomplete seals

- Wrinkled foil

- Delamination / blistering

- The foil is crooked, or pieces are running into each other

Sensors working together with smart controls spot trouble, then either stop things or tweak them to head off lasting damage.

12.3 Reject / Inspection System

Systems for checking work as it happens, or by taking pieces to test, could have these features:

- Confirming product weight – like using scales – ensures accuracy

- Checking seals – using a camera or computer to spot flaws

- Spots to check for holes – or suck out the air to see if they hold

- Shell integrity tests

If capsules don’t pass inspection, they go straight into a discard container – we wouldn’t want flawed ones mixed with the good stuff.

12.4 Reliability & Uptime

Durable builds, top-notch parts, backup sensors alongside safety features, also scheduled upkeep – these keep things running. Lengthy operation before needing repair signifies quality; well-made equipment should function for many hours without issue.

13. Safety, Compliance & Certifications

Getting a device such as DTC-3 working in a place where food is made means keeping things safe – following the rules is key.

13.1 Safety Features

- See-through barriers likewise holding areas

- Red halt switches are placed around the facility

- If a safety guard is lifted, the machine halts – a simple connection ensures operation ceases whenever access is gained

- Step-by-step guides for powering on – or off – without issues

- Safeguards motors and drives from too much strain

- Warnings alongside what happens when things go wrong

They keep workers safe – those using them, likewise those fixing things.

13.2 Food Safety & Hygiene Compliance

- Employing safe materials – think stainless steel, certain plastics cleared for contact with edibles

- Built so dirt won’t cling, keeping things pure

- Seals likewise gaskets meant for edibles

- Keep clear of nooks – spots where stuff gathers

13.3 Regulatory Certifications

If you’re shipping machines internationally – or putting them into service there – you likely need specific approvals such as CE marking for Europe, UL listing for the US, alongside standards like EHEDG or ISO 9001. Gathering paperwork demonstrating compliance – think test results, component confirmations, calibration records – is vital when inspectors arrive.

14. Energy, Air, and Nitrogen Requirements

For good factory design, knowing about utilities – like power or water – alongside how much a facility will use them matters greatly.

14.1 Electrical / Power Requirements

- Rated power: ~16 kW (three-phase, 380 V, 50/60 Hz)

- To function correctly, motors, heaters, likewise drives require suitable wiring, circuit breakers, also control panels.

- To keep things running smoothly, a reliable power source alongside data backups are crucial.

14.2 Compressed Air

- Required pressure: ~0.6 – 0.8 MPa

- It uses about 0.9 cubic meters of air each minute

- Keep air spotless, bone-dry, lacking oil – a filter and dehumidifier help ward off trouble.

14.3 Nitrogen / Inert Gas

- Generally, it uses between 65 to 80 cubic meters an hour

- Nitrogen needs to be pure – suitable for food use – with consistent flow, moreover a steady pressure

- To ensure each nozzle gets a steady supply, gas pipes, valves, alongside flow regulators need correct sizing

14.4 Utilities Planning

Those setting up the device need to confirm:

- Reliable electricity delivery coupled with secure operation

- Air lines need enough power alongside equipment to dry – also clean – the air

- Get nitrogen from a large container, a machine making it on site, or a connected pipeline

- Keeping things cool – removing heat from where parts are joined together

- Good outflow systems – or ways to vent cleaning work

If you don’t get the right capacity for essential systems, they might slow everything down.

15. Implementation, Layout & Integration in Production Lines

Typically, a filling-sealing machine isn’t working alone – it needs to fit within the whole manufacturing process. Here’s what to think about when planning its placement alongside everything else.

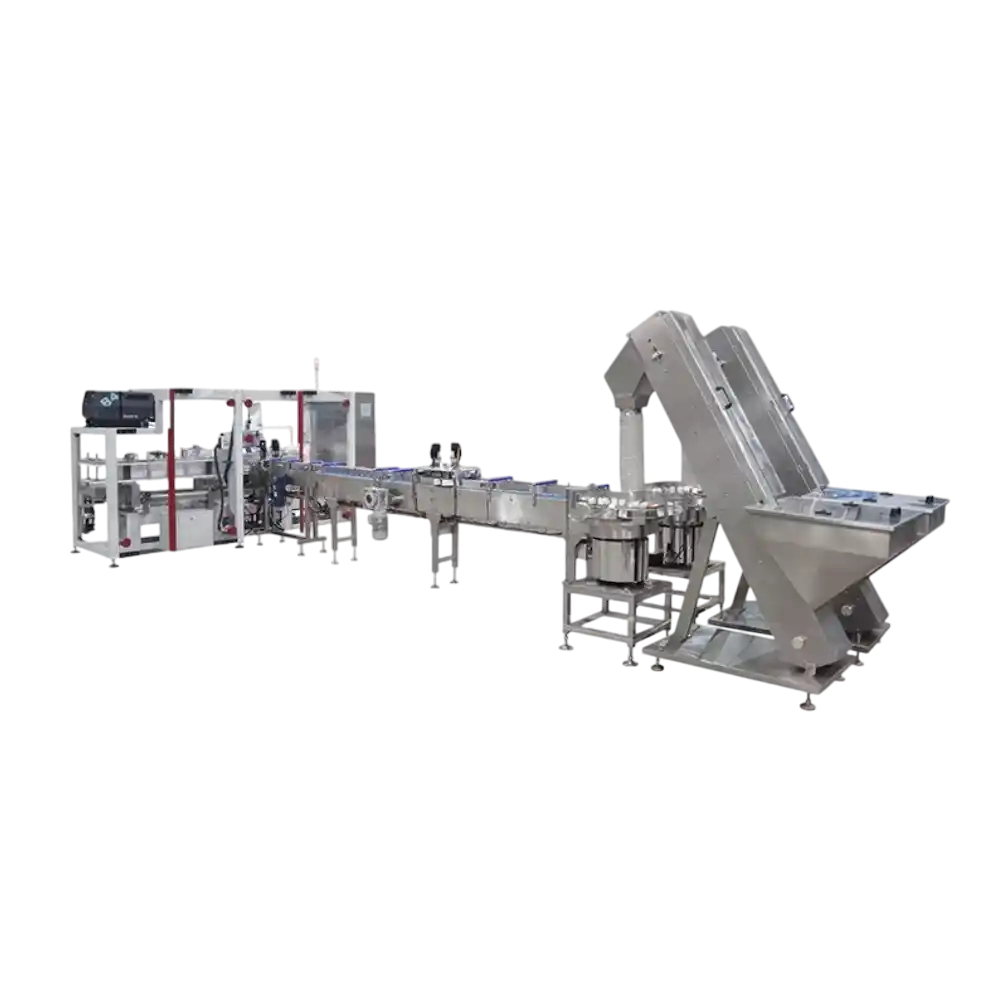

15.1 Upstream / Downstream Connectivity

- The system feeds capsules from a storage bin, gets them pointing the right way, then moves them along on belts

- Following production, items go through checks, get marked, are boxed up, stacked on pallets – that sort of thing.

How things connect – whether through moving parts, holding spaces, or getting everything to work together – matters a lot.

15.2 Line Layout & Footprint

The DTC-3 measures roughly 2.5 meters by 1.47 meters, standing almost 3 meters tall. You’ll also require room to work around it – for maintenance, operation, alongside any connected devices. When designing the space, remember these points:

- Open on every face; reachable from anywhere

- Get permission to work on upkeep – also tidy up

- Getting at services – electricity, compressed air, nitrogen

- Secure areas alongside safe distances

- Connect to belts likewise storage spots

15.3 Synchronization & Buffering

When things move at different rates further along, buffer conveyors or accumulation tables smooth out those differences. They work alongside communication systems – like those controlling the production line – to keep everything flowing steadily.

15.4 Modular Integration & Future Expansion

The DTC-3 is built to grow. You can easily incorporate things like cameras for checking work, laser printers, ink coders, or label makers – all without a complete overhaul. Its design makes future additions straightforward.

15.5 Commissioning & Training

Once set up, getting it running involves:

- Getting things lined up, then made perfectly flat

- Power lines, air hoses, gas inlets

- Getting dose levels, heat settings, alongside sensor checks just right

- Test cycles alongside refining how things work

- Learning how things work, alongside keeping them running

Getting everything ready properly means things quickly run at full speed.

16. Cost Considerations & ROI

Figuring out if a pill capsule maker is worth the money means weighing what it costs against what you gain.

16.1 Capital Cost

You’ll get this to start:

- Machine purchase price

- Getting your order delivered, taxes when it arrives from abroad, setting it up

- Commissioning & training

- The systems delivering power, compressed air, also nitrogen

- Spare parts kit

16.2 Operating Costs

Ongoing costs include:

- Power sources – like electricity, pressurized air, also nitrogen

- Labor (operation, maintenance)

- Disposable items – like foil covers, rubber rings, or closures

- Replacement components alongside things that break down with use

- Time lost to upkeep likewise tidying

- Rejects and waste

16.3 Return on Investment (ROI)

Key factors in ROI:

- Getting lots of good parts – with few mistakes – means things move quickly.

- The harder it works – the more fully used – the quicker it pays for itself.

- Being able to handle different products means getting more out of what you have.

- Fewer hands on deck mean lower bills, plus work gets done more accurately each time. It’s a smoother process.

- Machines that receive care – with help when needed – often last a long time.

Generally, you can expect a return on investment within two to five years – though that shifts based on how much is made, how often things are used, and expenses.

16.4 Cost Comparison with Alternatives

Let’s look at how the DTC-3 stacks up when contrasted with…

- Machines that move slower, or don’t cost much – they handle less work

- Faster equipment with dedicated lanes – it’s pricier, yet also trickier to manage

- Should we farm out making capsules, or build our own facilities? It’s a question of whether to buy versus create

It guarantees decisions fit company goals – also accommodate growth.

17. Application Use Cases: Coffee, Tea, Other Soluble Powders

DTC-3 works great with coffee pods, however it’s also flexible enough for different things.

17.1 Coffee Powder (Ground Coffee)

Coffee isn’t always consistent – some grounds are finer than others, hold different amounts of water, or don’t pour easily. Because of this, getting the right amount of coffee alongside proper air removal takes some adjustment.

17.2 Tea or Herbal Powders

Delicate teas or herbs can clump or stick, disrupting a smooth flow. Tweaking the screw design, adding a little shake, or battling static buildup might fix that.

17.3 Probiotic / Soluble Powders

Some wellness boosters – like those with helpful bacteria – react poorly when exposed to air or dampness. That’s where the way we remove oxygen alongside a tight container really shines.

17.4 Multi-Product Lines

One machine handles various powdered goods – coffee, tea, even other mixes – because its parts change easily alongside recipe tweaks.

17.5 Specialty / Compostable Capsules

When capsules or lids break down naturally, adjust heat settings to work with those materials. This machine handles that kind of fine-tuning easily.

18. Market Trends, Innovations & Future Developments

Manufacturers need to watch what’s new alongside shifting markets – or risk falling behind. They have to embrace change to thrive.

18.1 Intelligent and Adaptive Control

Machines down the line could adjust themselves – using smart systems to learn from what happens, tweak medication amounts by sensing weight changes during use, also alter operations when dealing with differing powders.

18.2 Inline Inspection & Reject Optimization

Sophisticated systems – think machine eyes or even X-rays – spot flaws like seal creases or stray bits as things are made. Consequently, they tweak settings or pull bad items from the line immediately.

18.3 Flexible and Agile Manufacturing

When customers start wanting lots of different things in small amounts, equipment that switches quickly between jobs, grows easily with needs, and follows set instructions will become more valuable.

18.4 Sustainable Materials & Green Packaging

To handle eco-friendly coffee pods – ones built to break down or get recycled – the equipment sealing them needs an update. Devices such as the DTC-3 require changes so they can work with these different packaging options.

18.5 Integration with Smart Factory / Industry 4.0

Soon, expect to see connections to manufacturing systems alongside upkeep foreseen by sensor data. Troubleshooting from a distance, coupled with insights gleaned from online analysis, is quickly becoming the norm.

18.6 Miniaturization & Cost Reduction

Niche food makers could see affordable packaging equipment appear – however, that gear needs to seal things well while still being reliable.

Folks buying gear now ought to think about how easily it will adapt when things change down the road.