Dolce Gusto Capsules: Innovation, Freshness, and the Art of Perfect Coffee Packaging

In today’s world of coffee innovation, Dolce Gusto capsules have become an icon of convenience, flavor consistency, and premium quality. Designed to deliver café-style beverages at home or in the office, these small but powerful capsules represent a revolution in how coffee lovers experience their daily brew. Behind the convenience of a single capsule lies a sophisticated process of precision engineering, airtight sealing, and advanced packaging technology. To maintain the aroma, taste, and freshness of each coffee variety, it is crucial that Dolce Gusto capsules are filled and sealed using high-quality machinery—an area in which DragonTechmac has earned its reputation as a trusted manufacturer and partner in the capsule coffee industry.

The Rise of Dolce Gusto Capsules

Dolce Gusto, a globally recognized brand of coffee capsules, was developed to meet the growing demand for fast, flavorful, and high-quality beverages. Unlike traditional brewing methods, which require ground coffee, filters, and precise water ratios, Dolce Gusto capsules make the process effortless. Each capsule is engineered to deliver a consistent taste, regardless of when or where it is brewed.

These capsules are not just containers; they are a fusion of coffee art and modern technology. Every detail—from the capsule’s shape to the material composition—serves a functional purpose: to preserve coffee’s volatile aromatic oils and delicate flavor compounds. The capsule acts as a barrier against light, air, and humidity, protecting the coffee inside from environmental degradation.

For coffee lovers, this means that each cup brewed from a Dolce Gusto capsule tastes as fresh as if the beans were ground moments before. But achieving this level of freshness and consistency is only possible through meticulous attention to the manufacturing and sealing process.

Why Capsule Quality Matters

A coffee capsule is more than packaging—it’s a miniature ecosystem that preserves the natural richness of coffee beans. Inside each Dolce Gusto capsule lies a carefully measured portion of coffee, perfectly roasted and ground to deliver the intended flavor profile. If the capsule fails to maintain airtight integrity, even slightly, the coffee can lose its freshness within days.

That’s why high-quality filling and sealing technology plays a central role in the Dolce Gusto ecosystem. The sealing process must create a perfect barrier that locks in flavor and blocks out oxygen. Only through precise machinery can this level of consistency be achieved.

Capsules that are improperly sealed may suffer from oxidation, leading to stale or flat-tasting coffee. Additionally, exposure to humidity can cause clumping or flavor loss. Every step, from grinding to sealing, must therefore be executed with precision.

Here, DragonTechmac stands out as one of the leading innovators in capsule filling and sealing technology. Their advanced equipment is designed to handle Dolce Gusto-compatible capsules with exceptional accuracy, ensuring every single capsule is filled to the correct weight, sealed at the correct pressure, and packaged in a way that guarantees long-term freshness.

The Science of Freshness in Dolce Gusto Capsules

Freshness is not an accident—it’s the result of science, technology, and precision engineering. Coffee beans, once ground, begin to release aromatic compounds almost immediately. These volatile oils are responsible for the rich aroma and flavor that make coffee so enjoyable.

In the Dolce Gusto capsule system, freshness is preserved through a combination of vacuum sealing and barrier materials. The capsule itself acts as a mini vault, locking in the aroma until the moment of brewing. However, to achieve this effect, the capsule must be sealed within milliseconds of filling. This rapid process prevents oxygen exposure, ensuring the natural flavor oils remain intact.

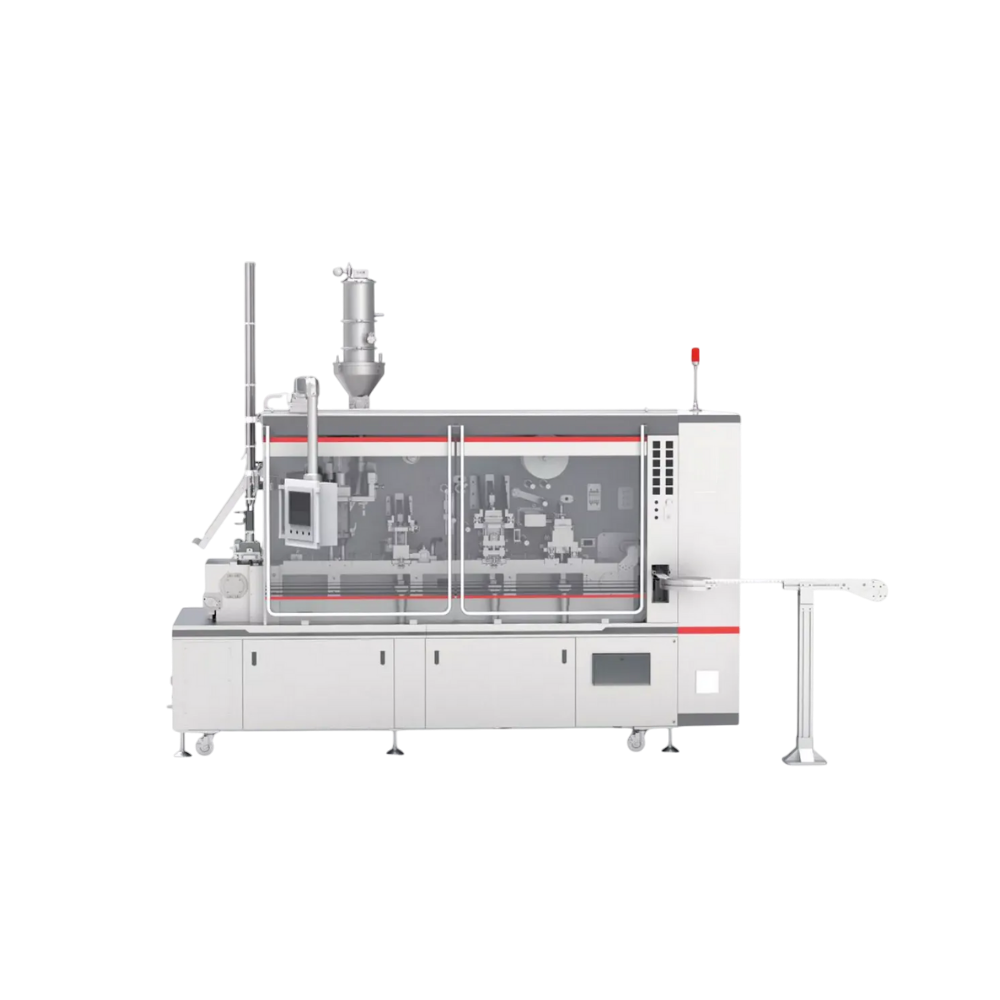

DragonTechmac’s filling and sealing machines are engineered specifically for this purpose. Using high-speed automation and intelligent control systems, their equipment ensures that every Dolce Gusto capsule is sealed under optimal conditions. The result is coffee that maintains its original aroma, taste, and crema quality for months after production.

By using precision sealing, coffee manufacturers can extend the shelf life of Dolce Gusto capsules while preserving the same fresh flavor as freshly roasted coffee.

DragonTechmac: Engineering Excellence in Capsule Production

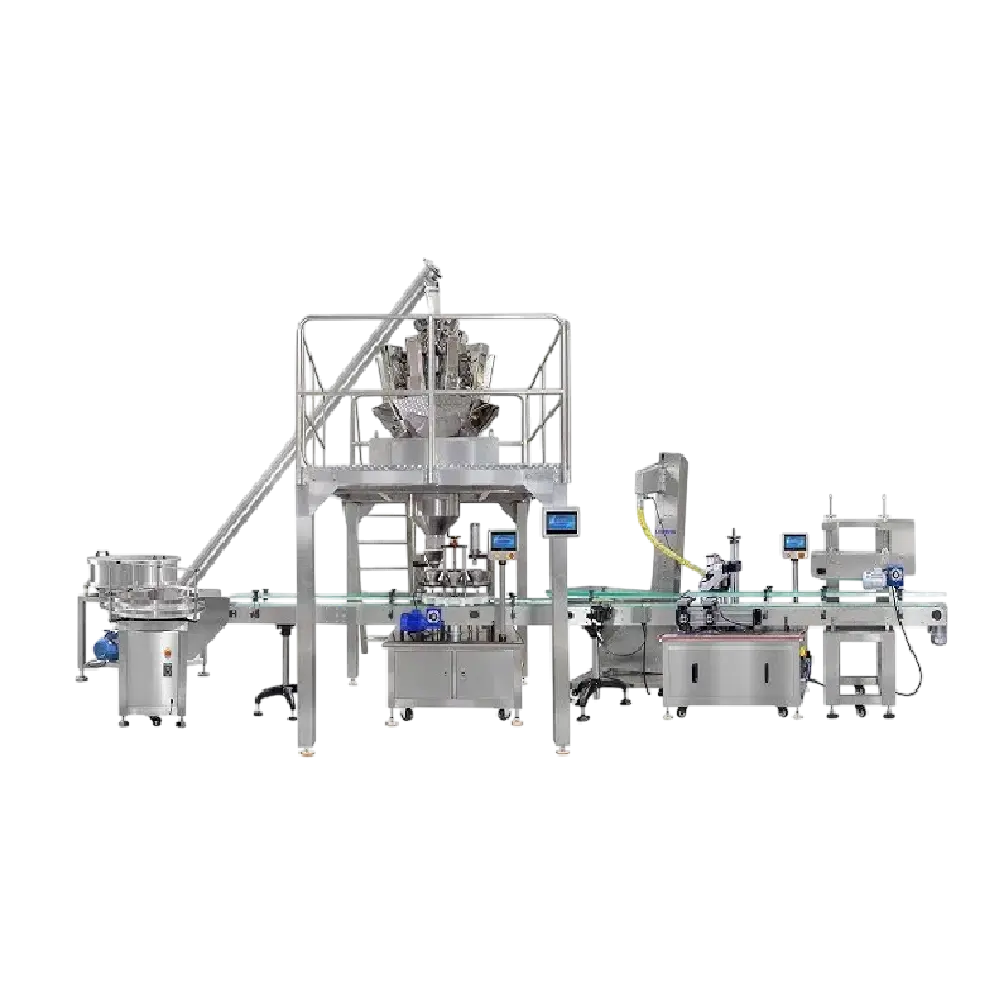

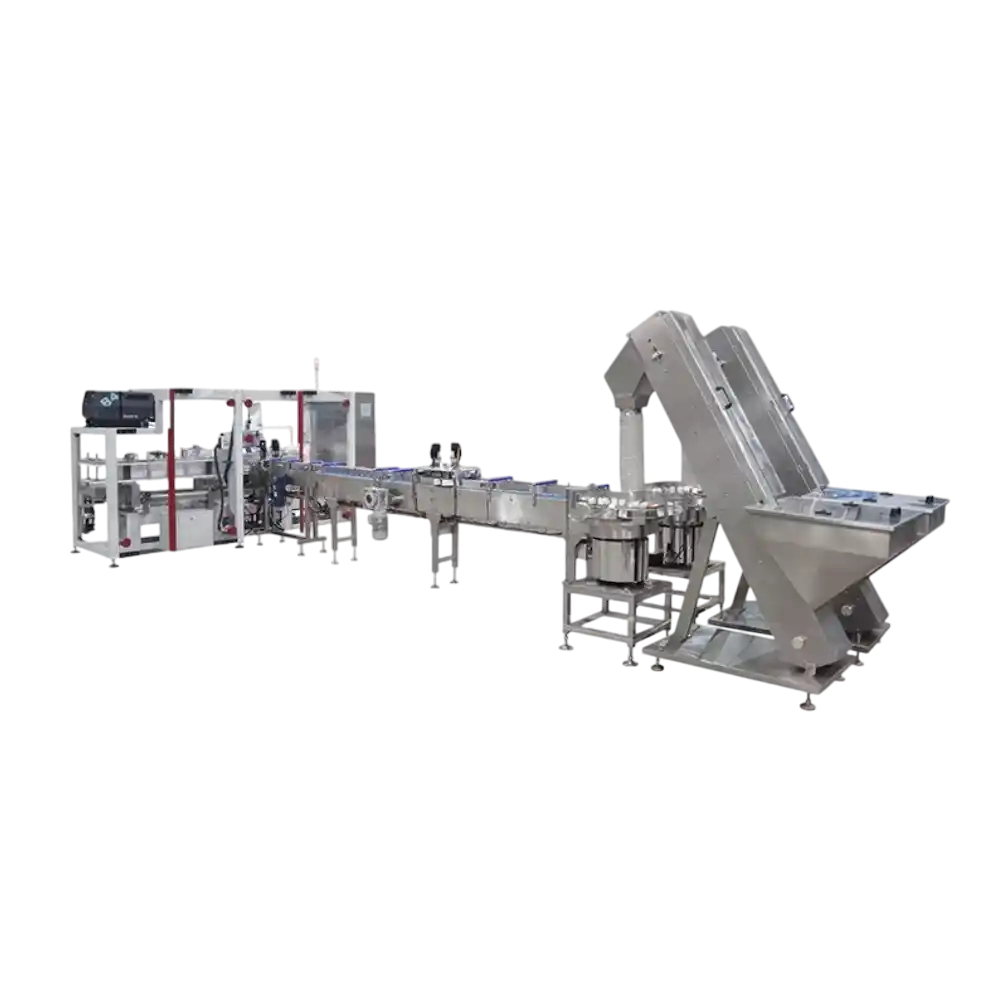

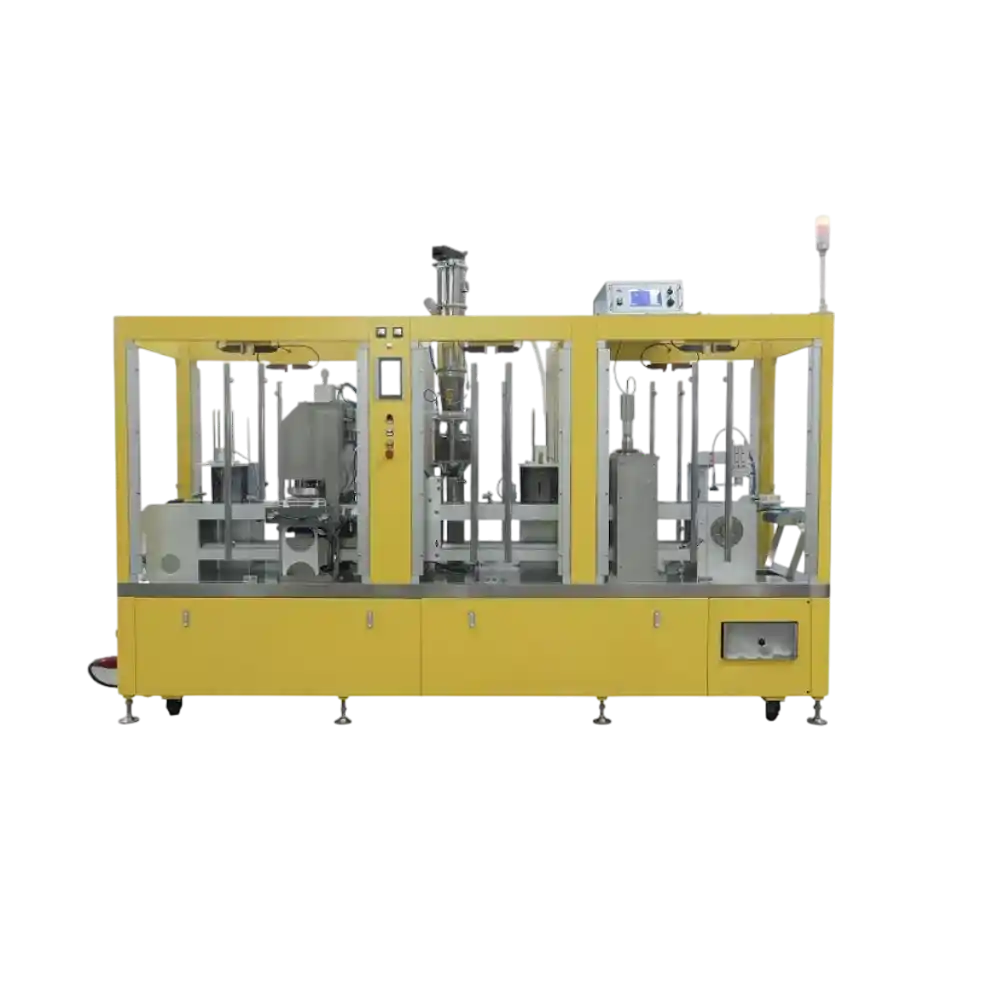

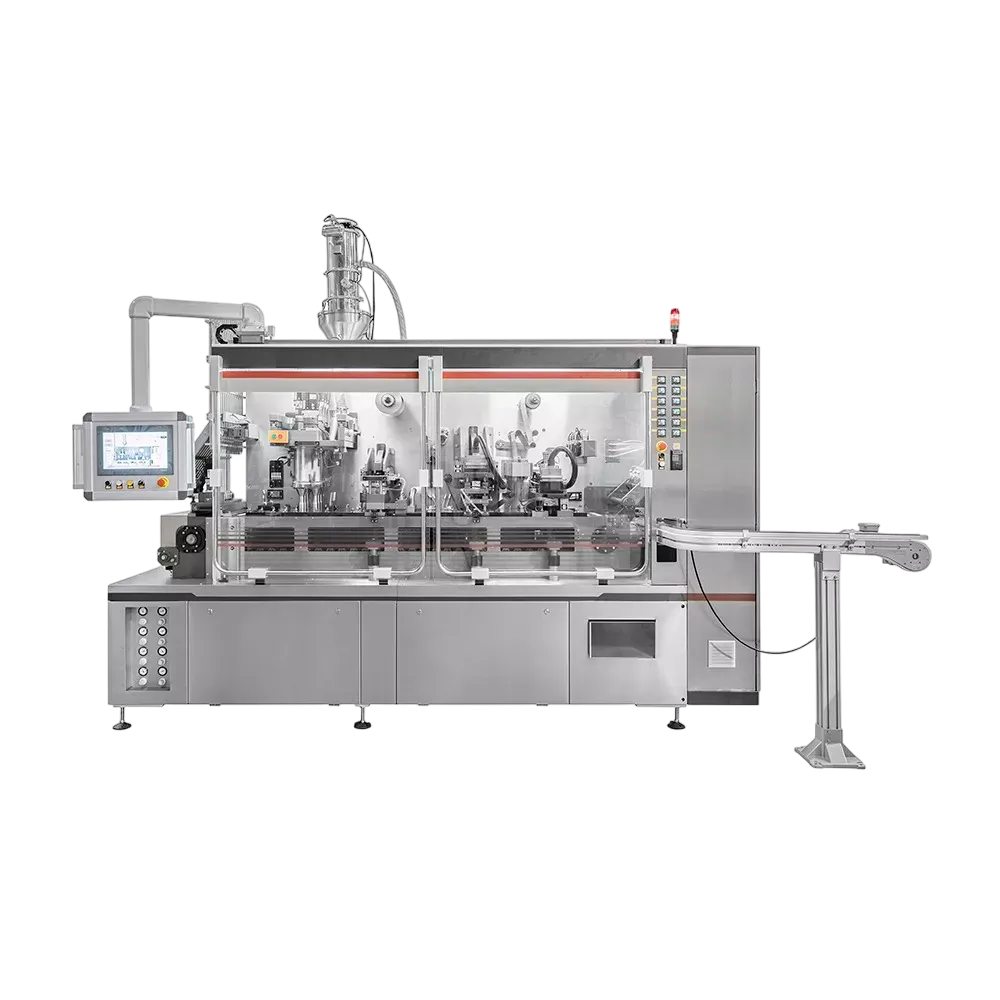

DragonTechmac has become synonymous with reliability and innovation in the capsule production industry. Specializing in Dolce Gusto-compatible capsule filling and sealing machines, the company provides cutting-edge solutions for coffee producers worldwide.

DragonTechmac’s machines are built for accuracy, efficiency, and durability. Each machine is designed to meet international food safety standards and deliver consistent performance even under high production volumes. With intelligent sensors and automated controls, DragonTechmac ensures that each capsule receives the precise amount of coffee required for perfect extraction.

What sets DragonTechmac apart is its commitment to sealing precision. The company’s machines use advanced heat-sealing technology to ensure that each Dolce Gusto capsule is hermetically sealed, maintaining its freshness and protecting it from air infiltration. This level of precision not only preserves flavor but also enhances consumer satisfaction by ensuring consistent brewing results.

Furthermore, DragonTechmac’s technology supports multiple capsule types, allowing coffee producers to adapt to various formats—such as Nespresso, K-Cup, Lavazza, and of course, Dolce Gusto—without compromising on quality.

The Role of Packaging in Maintaining Coffee Quality

While filling and sealing are critical, packaging also plays a vital role in the quality preservation of Dolce Gusto capsules. After sealing, the capsules must be packaged in materials that offer additional protection against moisture and temperature variations.

A high-quality packaging process involves using multilayer films, nitrogen flushing, and vacuum technology to ensure that no external factors affect the capsules. When combined with precise sealing, this process guarantees that coffee stays as aromatic and flavorful as the day it was encapsulated.

DragonTechmac’s automated packaging systems are designed to complement their capsule sealing machines. These integrated systems allow producers to manage the entire process—from filling to final packaging—under one unified operation, minimizing handling and maximizing product hygiene.

By maintaining full control over the production chain, coffee companies can ensure that their Dolce Gusto capsules reach consumers in perfect condition, delivering the ultimate coffee experience every time.

Consistency: The Key to Brand Trust

In the competitive world of coffee, consistency is everything. Customers who enjoy Dolce Gusto coffee expect the same rich taste with every cup. This level of reliability builds trust and brand loyalty. Achieving it, however, requires precise control over every detail of production.

Even small variations in filling volume or sealing pressure can affect the flavor, aroma, and extraction of the coffee. Therefore, manufacturers rely on advanced machines—like those developed by DragonTechmac—to ensure absolute uniformity.

DragonTechmac’s systems feature automated calibration and quality inspection tools that detect even the slightest deviations. This ensures that each Dolce Gusto capsule leaving the production line meets the same high standards of excellence.

With technology-driven consistency, coffee brands can maintain their reputation and stand out in a market where consumers value both taste and trust.

Sustainability and Modern Capsule Technology

The modern coffee industry is moving towards sustainable production practices, and Dolce Gusto capsules are no exception. Many coffee companies are now exploring recyclable materials, biodegradable plastics, and eco-friendly production methods.

DragonTechmac supports this shift by developing machinery that accommodates new capsule materials without compromising performance. Whether the capsules are made of aluminum, compostable PLA, or food-grade plastic, DragonTechmac’s filling and sealing machines are adaptable to meet the latest sustainability standards.

Sustainability is not only about materials—it also involves energy-efficient production. DragonTechmac’s systems are designed to minimize waste, reduce energy consumption, and optimize output. By integrating intelligent automation, manufacturers can achieve a smaller carbon footprint while maintaining product quality.

This alignment of environmental responsibility and technological advancement reflects the future of the Dolce Gusto capsule industry—one where great taste and sustainability go hand in hand.

The Importance of Choosing the Right Filling and Sealing Machine

For coffee producers, the choice of filling and sealing equipment is one of the most important decisions in capsule production. A reliable machine ensures not only high output but also product consistency, safety, and longevity.

DragonTechmac’s Dolce Gusto capsule machines are equipped with precision weighing systems, servo-driven filling mechanisms, and automatic sealing temperature control. This ensures each capsule is filled to the exact target weight, sealed perfectly, and delivered ready for packaging.

In an industry where small details define product quality, DragonTechmac offers unmatched reliability. The company’s engineers understand the delicate balance between speed, precision, and coffee preservation. That’s why their systems are used by professional coffee producers around the world who demand excellence in every capsule.

Delivering the Perfect Cup Every Time

The true success of Dolce Gusto capsules lies in the experience they create for the consumer. Every time a user inserts a capsule into the machine and presses the brew button, they expect perfection—aroma, crema, and flavor balance.

This seamless experience begins long before brewing; it starts on the production line, where high-quality machines like those from DragonTechmac ensure that each capsule is properly filled, sealed, and protected. When coffee is preserved at its peak freshness, the end result in the cup reflects it.

Each sip becomes a testament to advanced engineering, premium coffee sourcing, and attention to detail—a symphony of technology and taste.

Final Thoughts

Dolce Gusto capsules represent more than a convenient coffee solution—they symbolize the fusion of craftsmanship and technology. From the selection of premium beans to precision grinding, from meticulous filling to flawless sealing, every step defines the final taste.

To preserve the original quality of the coffee, a reliable sealing and packaging system is indispensable. Poor sealing can destroy months of careful sourcing and roasting, while superior sealing—like that provided by DragonTechmac’s advanced machinery—protects the essence of coffee for months, ensuring that consumers always enjoy the same rich, aromatic experience.

In a world where coffee quality defines brand reputation, investing in high-performance capsule technology is not just an operational choice—it’s a strategic necessity. Dolce Gusto capsules continue to lead the market because they combine flavor excellence with technological precision. And at the heart of that process are the machines that make it possible—machines that seal not just coffee, but quality, freshness, and customer satisfaction.