| Parameter | Typical Value |

| Production Speed | 50–60 capsules per minute (≈ 3,000 capsules/hr) |

| Filling Weight | 5.0 – 5.5 g |

| Filling Accuracy | ±0.2 g (averaged over large batches) |

| Power Supply | 3‑phase 380 V / or single phase AC 220 V, 50/60 Hz, ~3.5 kW |

| Compressed Air Pressure | 0.6 – 0.8 MPa |

| Air Consumption | ~0.6 m³ per minute |

| Machine Weight | ~500 kg |

| Dimensions | ~680 mm × 680 mm × 1,687 mm (HxWxD) |

| Material – contact parts | SUS304 stainless steel |

| Manufacturing Standards | CE, SGS, ISO 9001 |

| Sealing Material | Foil or sealing film (roll-fed) |

| Feeding Method | Vacuum (for powder feed) |

| Mold Changeover | Quick-switch mold sets |

| Efficiency Feature | ~30% foil saving in the sealing process |

Introduction

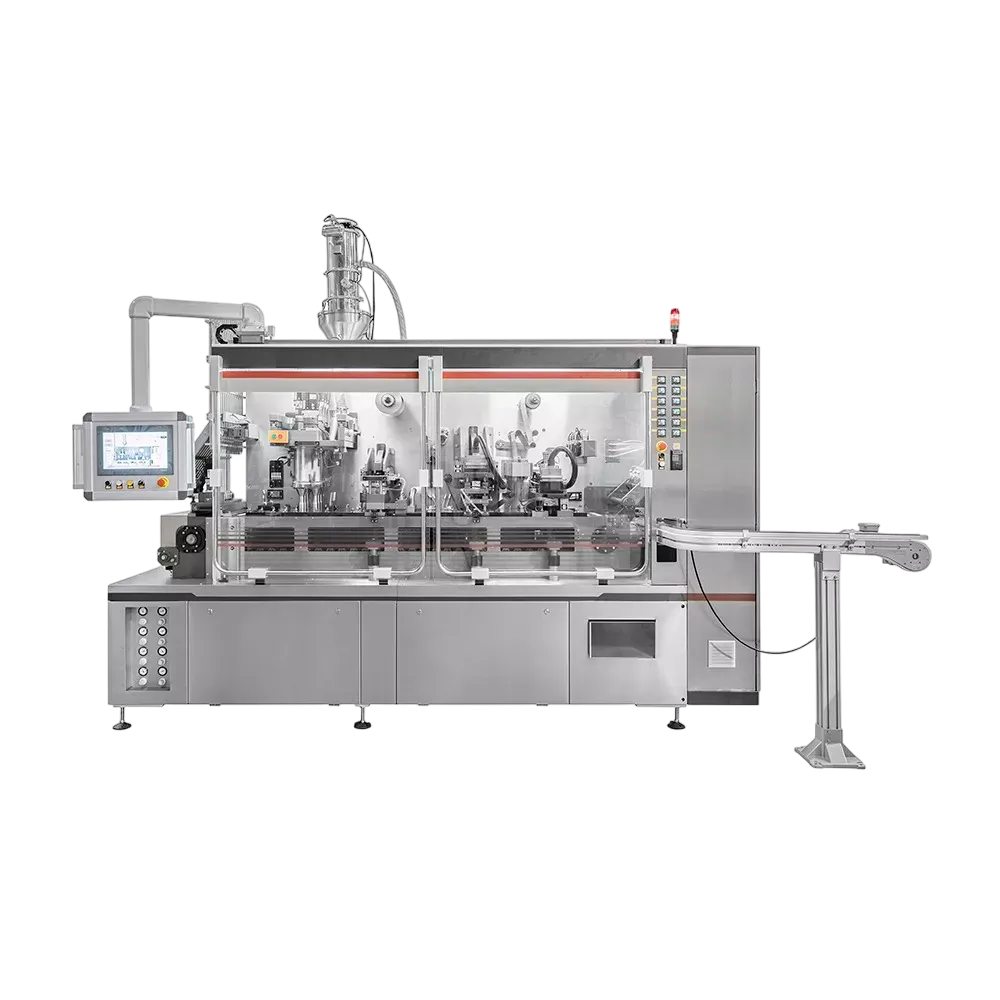

In the evolving world of specialty coffee, premium on-demand capsule production is no longer reserved for giant manufacturers. Smaller roasters, boutique brands, and entrepreneurial startups now have access to compact, high-efficiency systems that allow them to package coffee pods in-house. Among these, the modern coffee capsule filling machine stands out as a pivotal tool — enabling private-label capsule creation, small-batch experimentation, and robust product consistency.

A well-engineered coffee capsule filling machine ensures precision dosing, airtight sealing, optional nitrogen flushing, and reliable throughput — all in a compact footprint. For operations that want to maintain freshness, maximize yield, and assure repeatable quality, such machines are essential.

In this article, we will explore, in depth:

Core functional modules and subsystems of a coffee capsule filling machine

Key technical specifications often expected

Advantages and business use-cases

Design and engineering considerations

Best practices in operation, cleaning, maintenance, and quality control

Compatibility and consumables (capsule shells, sealing foils, etc.)

Environmental and sustainability aspects

Troubleshooting common issues

Tips for scaling and upgrading

Throughout, I will consistently use the target phrase “coffee capsule filling machine” to emphasize the core concept, while offering a richly detailed narrative that is SEO-friendly, readable, and useful for potential buyers, engineers, or coffee professionals.

Overview and Functionality

What Is a Coffee Capsule Filling Machine?

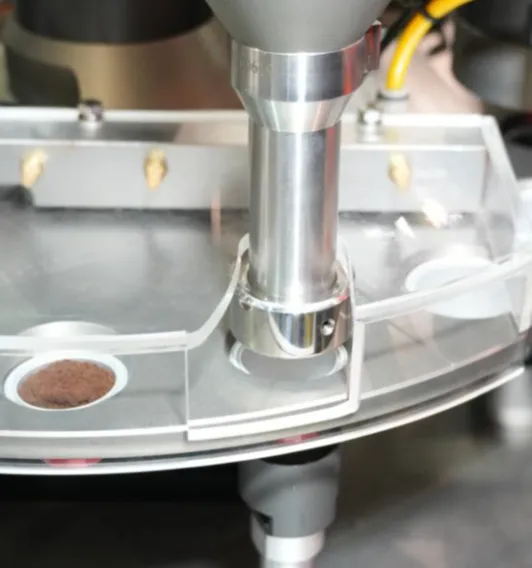

A coffee capsule filling machine is an automated system designed to take empty capsule shells (e.g. for Nespresso-style pods or similar formats), fill them with a precise dose of ground coffee (or other powdered contents), optionally flush or purge with inert gas (e.g. nitrogen), and then reliably seal the capsule with a foil or laminated lid. The result is a hermetically sealed, shelf-stable coffee pod ready for retail sale or internal use.

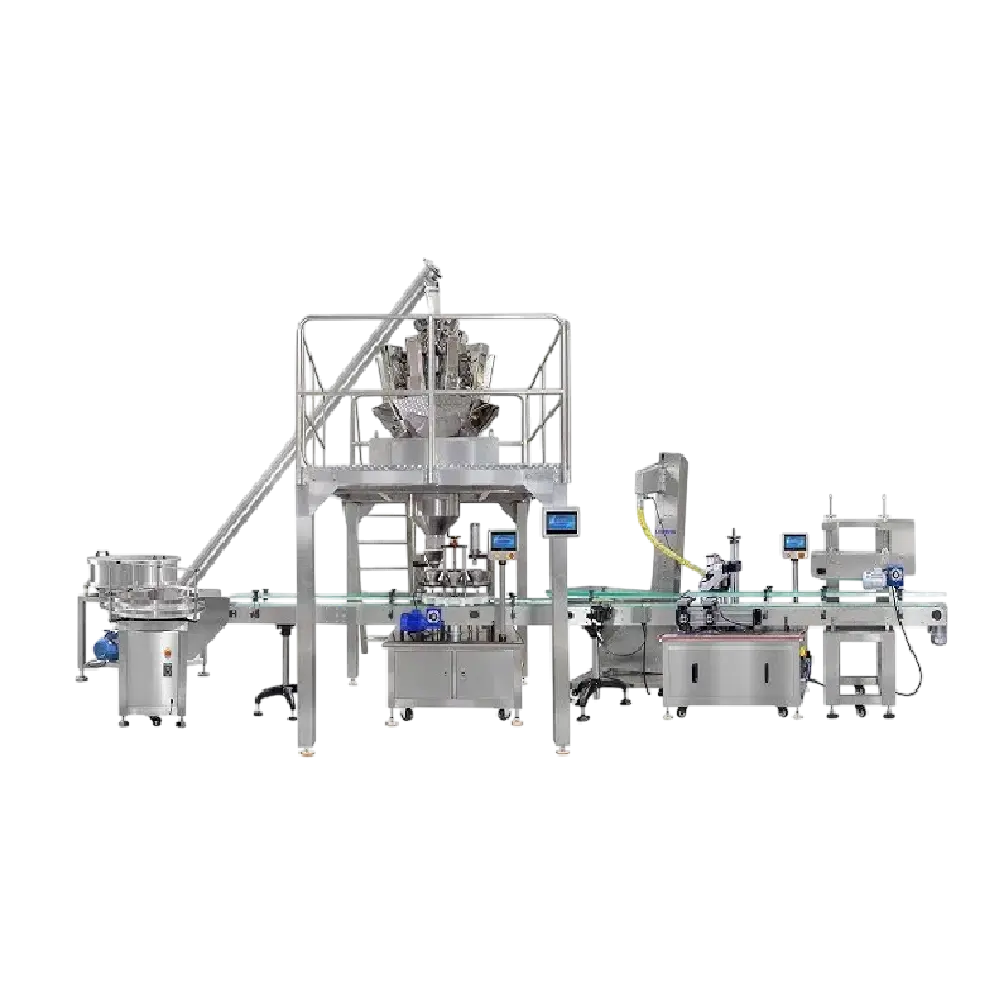

The machine integrates several modules that work in concert:

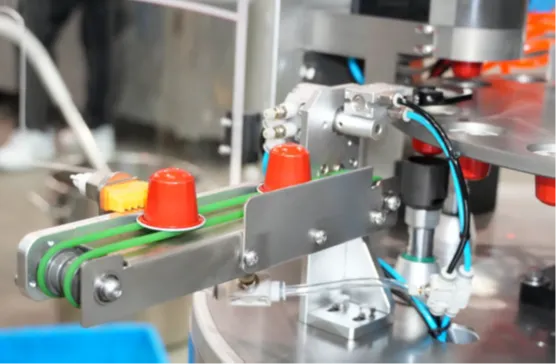

Capsule feeding / handling – presenting empty capsules into the process line

Powder feeding & metering – delivering a consistent dose of coffee powder into each capsule

Gas flushing (optional) – replacing or displacing oxygen inside the capsule to improve shelf life

Sealing module – applying and heat-sealing the foil lid

Conveyor / output – moving sealed capsules to a collection bin or downstream packaging

Control system / user interface – monitoring parameters, alarms, and machine status

Well-designed machines balance throughput, precision, maintainability, and footprint.

Typical Applications

Some of the common scenarios where a coffee capsule filling machine is deployed include:

Specialty coffee roasters wanting to launch their own capsule line

Private-label capsule brands producing small- to medium-scale runs

R&D and pilot lines testing blends, roast levels, or capsule formats

Contract packaging houses offering turnkey capsule filling services

Quality assurance / sample labs that need consistent capsule production internally

Because of evolving consumer demand for capsule-format coffee, the ability to bring capsule filling in-house provides strategic flexibility and control over branding, flavor, shelf life, and margins.

Key Technical Specifications & Performance Metrics

When evaluating a coffee capsule filling machine, the following technical parameters and metrics are crucial. (These are drawn and extended from the specification source you provided, adapted generically.)

| Spec Category | Typical Value / Range | Notes & Importance |

|---|---|---|

| Throughput / Capacity | ~ 50–60 capsules per minute (≈ 3,000 pods/hour) | A benchmark for small-scale machines. Some may reach higher. |

| Filling accuracy / tolerance | ±0.2 g (averaged over large sample) | High precision ensures consistent taste and avoids over / underfilling. |

| Filling weight (dose) | ~ 5.0–5.5 g (per capsule) | Common dose range; adjustable for lighter/heavier pods. |

| Feeding / metering method | Vacuum feeder + servo motor–driven auger screw | Provides stable and accurate powder flow. |

| Materials in contact | Food-grade stainless steel (SUS304), plus aluminum, plastic parts | Ensures hygiene and durability. |

| Power / electrical | Three-phase 380 V / or AC 220 V single-phase, ~ 3.5 kW | Ensure proper electrical infrastructure. |

| Compressed air | 0.6–0.8 MPa | Needed for pneumatic operations (ejectors, lids, etc.). |

| Air consumption | ~ 0.6 m³/min | For sustained throughput. |

| Machine weight | ~ 500 kg | Substantial but manageable for a factory floor. |

| Machine footprint / dimensions | ~ 680 × 680 × 1,687 mm | Compact design under 1 m² footprint. |

| Sealing foil saving | ~ 30% reduction possible | Some machines optimize foil usage. |

| Mold changeover | Quick change features | For switching capsule types or formats. |

| Standards / certifications | CE, ISO 9001, SGS | Demonstrates compliance with quality and safety norms. |

These parameters form a baseline reference for what to expect in a modern mid-volume machine. A well-engineered coffee capsule filling machine will deliver consistent performance across these metrics while allowing flexibility, ease of operation, and minimal downtime.

Advantages & Benefits of Adopting a Coffee Capsule Filling Machine

Consistency & Quality Control

One of the primary benefits is repeatable precision. Manual or semi-manual capsule filling systems often suffer from variation in dose, inconsistent packing, and sealing defects. A full automated coffee capsule filling machine minimizes those errors, ensuring that each pod meets predetermined standards of weight, seal integrity, and freshness.

Freshness and Shelf Life Enhancement

The integration of a nitrogen flushing or inert-gas purging module is central to preserving the aromatic compounds of coffee. Removing or displacing oxygen before sealing helps reduce oxidation, maintaining flavor, aroma, and overall product stability over extended shelf life.

Efficiency & Labor Savings

A single machine can often replace multiple manual operators. When throughput is in the thousands of pods per hour, the labor savings become significant. By automating feeding, dosing, and sealing, staff can be redeployed to quality control, maintenance, or scaling tasks.

Compact Footprint & Scalability

Modern machines designed to occupy less than 1 m² enable capsule production in small production spaces or existing roastery floors without major reconfiguration. As demand grows, adding parallel machines or upgrading to multi-lane systems is straightforward.

Flexibility & Private Label Capability

By having control over capsule production, a business can experiment with blends, roast levels, packaging formats, and branding. This agility allows differentiation in a competitive market. The ability to produce small or medium runs is also attractive for pilot launches or seasonal variants.

Raw Material Efficiency

Better control over dose accuracy and foil sealing leads to reduced scrap, lower material waste, and more efficient foil use (some designs claim up to 30% foil savings). This contributes to lower per-unit costs.

Brand Value & Market Positioning

Producing your own capsules gives you full control of brand identity, labeling, freshness messaging, and supply chain integrity. Consumers often respond favorably to brands that can tout direct-to-capsule freshness and vertical integration.

Design & Engineering Considerations

Designing or selecting a robust coffee capsule filling machine entails careful attention to mechanical, pneumatic, material, control, and maintainability aspects. Below are key considerations.

1. Powder Handling & Dosing

Vacuum or negative-pressure feeding is often used to draw coffee powder into a buffer hopper or vibrating channel, reducing segregation and bridging.

The use of a servo-driven auger screw enables variable speed, precise control and rapid adjustment for different dosing weights.

The system should guard against clogging, caking, or static charge buildup, which can disrupt consistent feeding.

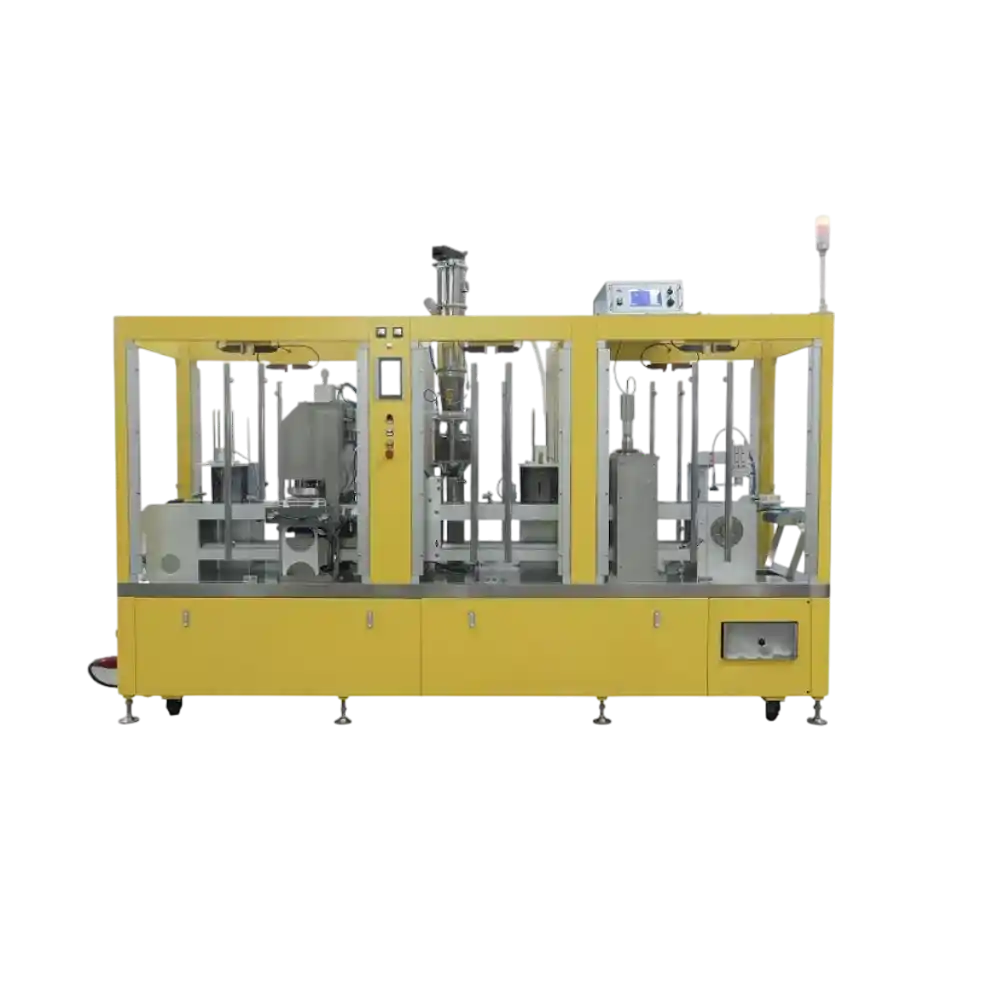

2. Capsule Shell Handling

The mechanical path must ensure correct orientation, positioning, and retention of capsule shells without damage.

Ejectors or blowers may reject incorrectly seated capsules or defective shells.

Compatibility with multiple capsule formats (different diameters, heights, shell materials) can be a design advantage, often enabled via modular or swappable tooling.

3. Gas Purging / Nitrogen Flushing

The design must achieve effective displacement of oxygen, ideally targeting <1% residual O₂ inside capsule.

Gas nozzles must reach within the capsule without interfering with powder deposition.

Flow control, pressure stability, and synchronization with capsule movement are critical.

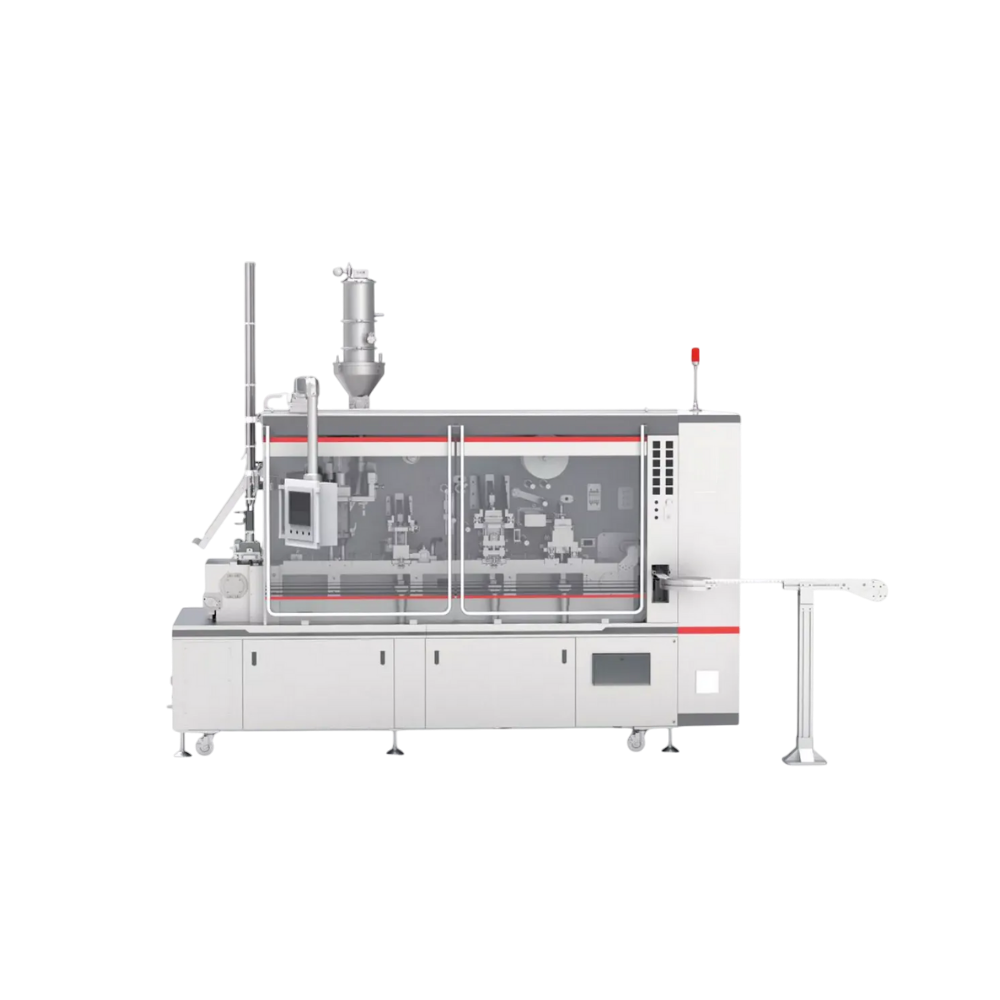

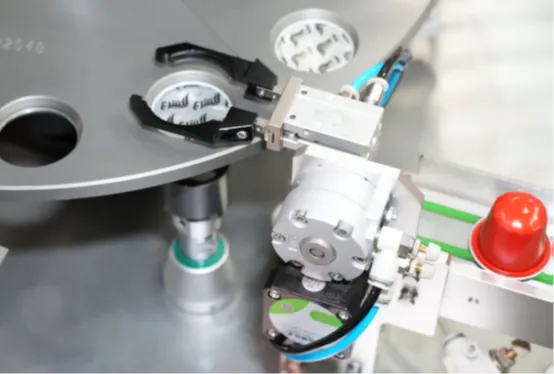

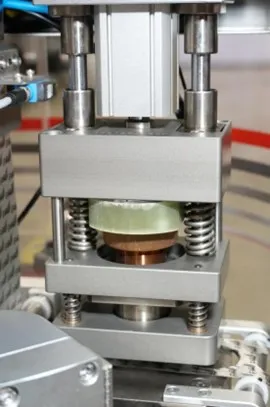

4. Heat Sealing Module & Foil Handling

Sealing must be uniform, free of wrinkles or leakage, and retain mechanical integrity (foil adhesion) for shelf durability.

Foil roll unwinding, tensioning, die alignment, and foil transfer must be precise and easy to adjust.

Quick mold or die changeover is valuable for multi-format operations.

Energy efficiency and cooling for sealing parts help maintain consistent heat profiles.

5. Mechanical Structure & Frame

Food-contact surfaces should be stainless steel (e.g. SUS304) and meet hygiene and cleaning standards.

The overall frame must resist vibration, be rigid, and allow easy access for maintenance.

Guards, covers, and safety interlocks are essential for operator safety.

6. Control System & User Interface

A robust PLC (programmable logic controller) drives synchronization of feeders, conveyors, motors, sensors, and alarms.

A human-machine interface (HMI) displays status, allows recipe selection, and error handling.

Logging of production data, weight readings, reject rates, and alarms helps quality assurance.

Sensors (optical, proximity, load cells) guarantee alignment, detect jams, and trigger stoppages.

7. Maintenance, Cleaning & Changeover

Tool-less or quick-release parts help facilitate fast cleaning or conversion.

Accessible modules reduce downtime.

CIP (clean-in-place) or dry-cleaning paths reduce labor intensity.

Spare parts (seals, O-rings, belts) should be easily spares-supplied.

8. Safety, Certification & Compliance

Guarding, emergency-stop, interlock systems, and safety shields conform to applicable machinery safety standards.

Certifications such as CE, ISO 9001, and third-party inspection (SGS) reinforce reliability and compliance.

Electrical wiring, grounding, and motor protections must meet local industrial codes.

Best Practices for Operation & Quality Assurance

1. Prestart Checks & Setup

Verify power, air pressure, and gas supply (nitrogen, if used) are at required levels.

Confirm that the hopper is clean and filled with degassed, properly sieved coffee.

Load the foil roll (sealing foil) and set correct tension, alignment, and registration marks.

Adjust dosing recipe for the current capsule format and coffee blend.

Run a few test capsules in purge or dry-run mode (no filling) to validate shell movement and sealing.

2. Calibration & Weighing

Use a precision balance to sample 20–50 capsules periodically.

Calculate average weight and standard deviation; ensure tolerance (e.g. ±0.2 g) is met.

Adjust the servo feed speed or auger calibration as needed.

Monitor reject rate and seal integrity.

3. Monitoring & Quality Inspection

Visual inspection of sealed capsules for wrinkling, leakage, or foil delamination.

Periodic oxygen content checks using a headspace analyzer (if gas flushing is used).

Check for coffee fines or dust around the sealing edge (which may compromise foil adhesion).

Measure moisture content in the coffee before filling to prevent humidity-induced issues.

Maintain logs of machine uptime, rejects, maintenance events.

4. Cleaning & Sanitation

Schedule daily, weekly, or monthly cleaning depending on production.

Disassemble and clean powder paths, hopper, auger, nozzles, and sealing surfaces.

Use food-grade cleaning agents and ensure thorough drying before restarting.

Always perform a short warm-up run with no coffee (or inert filler) to purge cleaning residues.

5. Preventive Maintenance

Check belts, couplings, bearings, and motors regularly.

Inspect pneumatic cylinders, seals, and filters.

Replace worn parts proactively (e.g. O-rings, sealing dies, nozzle tips).

Update firmware or PLC logic if manufacturer issues enhancements.

Keep a spare parts kit on hand to minimize downtime.

6. Troubleshooting Common Issues

Underfill or overfill → adjust servo dosing or calibrate auger feed.

Foil seal failure / leakage → check foil alignment, heat profile, cleanliness of sealing surfaces.

Jamming or capsule misfeeds → inspect capsule path, remove debris or defective shells.

Excess gas consumption or poor flushing → verify gas pressure, nozzle alignment, leakages.

High reject rate → analyze roots (dosing variation, shell defects, foil defects) via QC logs.

Consumables & Compatibility

A coffee capsule filling machine must interface with several consumables and materials. Ensuring compatibility is key to long-term operation.

Capsule Shells / Pods

Empty capsules (shells) may be aluminum, plastic, compostable, or biodegradable materials.

Dimensional tolerance (diameter, wall height, rim thickness) must match the tooling.

Shells must be clean, free of burrs, and compatible with the sealing material.

Material selection (e.g. PBT, PP, or biodegradable polymers) influences sealing characteristics and shelf behavior.

Sealing Foil / Lids

Sealing foil can be aluminum, laminate, or composite films.

Foil must be formable, sealable (heat seal compatible), and robust enough to protect from moisture and oxygen ingress.

Foil roll width, thickness, and tensile properties should be compatible with the machine’s sealing die.

Some machines allow foil saving features (e.g. ~30% less foil waste) by reducing unnecessary margins.

Gases (Nitrogen or Inert Gas)

Food-grade nitrogen (or argon or CO₂ blends) is used for flushing.

Purity, pressure, flow regulation, and dew point must meet operational standards.

Proper piping, valves, regulators, and flow controllers are required.

Leak-tight connections prevent overconsumption.

Filters, Sieves, and Pre-Processing

Coffee powder may need sieving or degassing before feeding to reduce fines or static.

Filters on vacuum lines help prevent contamination.

Air filters and driers protect pneumatic components from moisture or debris.

Spare Parts & Wear Items

Sealing dies, O-rings, nozzles, belts, bearings, and couplings are commonly replaced.

Having a consumables kit ensures minimal downtime.

Matching spare tooling for alternative capsule formats supports flexibility.

Environmental & Sustainability Aspects

In a world ever more conscious of sustainability, the design and operation of a capsule filling line have environmental implications. Forward-looking operators and brands should consider:

Biodegradable / Compostable Capsules

Using biodegradable or compostable capsule shells (e.g. PLA, PHA blends) aligns with ecological goals.

Sealing processes may need adjustment (lower temperatures or modified adhesives) to accommodate these materials.

Proper certification (e.g. OK compost, ASTM D6400) enhances brand credibility.

Foil Reduction & Material Efficiency

Machines that reduce foil waste (via tighter margins or foil-saving algorithms) cut material usage and cost.

Reclaimed foil scrap may be recycled if uncontaminated.

Optimizing dose accuracy reduces coffee waste, which has downstream environmental impact.

Energy Efficiency

Efficient heating elements, insulation, and power management reduce energy consumption.

Use of standby modes or sleep states when idle saves electricity.

Good mechanical design reduces friction and motor load.

Gas Usage Optimization

Efficient sealing and gas purging strategies minimize inert gas consumption.

Use of proper regulators, flow control, and leak-tight plumbing reduce waste.

Inert gas recovery or recycling may be explored in larger scale operations.

Lifecycle & Upgradability

Machines built modularly and serviceably tend to have longer useful life.

Upgradable modules (e.g. additional lanes, updated control boards) reduce need for full replacement.

Responsible disposal or refurbishment at end-of-life aligns with circular economy principles.

Use Cases & Business Scenarios

Small Roaster Launching a Capsule Line

A specialty roaster producing thousands of bags per week may wish to pilot a capsule line without outsourcing. By installing a compact coffee capsule filling machine, they can test market reaction, tweak blends, adjust roast profiles, and establish branding — all under controlled conditions. If demand rises, they can scale by replication.

Private Label / White-Label Capsule Production

A contract filler can purchase one or more machines to offer turnkey capsule filling services for multiple brand clients. With accurate dosing, traceability, and flexible format switching, they can serve premium coffee brands and small entrants alike.

R&D or Pilot Testing

In a product development lab, trialing new blends, roast levels, or specialty ingredients (e.g. micro-lot coffee, flavored inclusions) requires reliable small-batch capsule production. A compact coffee capsule filling machine enables this without committing to large-scale lines.

Seasonal or Limited-Edition Capsule Runs

Coffee brands may want to produce limited edition or seasonal capsule batches (holiday blend, single-origin experiments). The flexibility of having an in-house filling machine allows lean runs without overcommitting capacity.

Quality Assurance & Benchmarking

Even larger capsule manufacturers may install a smaller machine in QA or R&D to cross-check production consistency, test new foils or shell materials, or validate roast-to-capsule outcomes.

Architecture & Workflow: Step-by-Step Process

Let’s walk through a typical operational workflow inside the machine to see how the modules cooperate.

Loading Empty Capsules

The operator loads a hopper or vibratory feeder with empty capsule shells. The handling system orients and positions them into the feed path.Capsule Transfer & Positioning

A conveyor or linear shuttle carries individual capsules to the filling station. Position sensors or mechanical guides ensure accurate alignment.Powder Feeding & Dosing

Coffee powder, held in a supply hopper, is fed (via vacuum or vibratory means) to a buffer. From there, a servo-driven auger delivers the precise dose into the capsule through a dosing nozzle or funnel.Gas Flushing (Optional)

While the capsule sits in the filling station or just after it, nitrogen (or inert gas) is flowed into the interior to displace oxygen. The purge must be synchronized not to disturb the powder bed.Foil Application & Sealing

Pre-cut or roll-fed foil is aligned over the capsule mouth. A heating/sealing platen presses and bonds the foil to the capsule, forming a hermetic seal.Cooling / Dwell Time

After heat sealing, the capsule may be held briefly or cooled to allow the bond to stabilize. Some machines integrate chill or natural cooling.Ejection / Output

The sealed capsule is released from the mold and carried downstream via conveyor or chute to a collection bin or packaging line.Inspection & Rejection

Sensors or manual check stations inspect for defects. Defective capsules (e.g. seal failures, underfill) are ejected to a reject bin.Data Logging & Feedback

The machine logs production count, rejection rate, weight deviations, and status. Operators monitor via HMI and adjust as needed.Recipe Changeover / Format Switching

If switching capsule formats or recipes, modules such as molds, sealing dies, and dosing settings are changed. Quick-change tooling minimizes downtime.

Practical Tips & Recommendations

Start with the right capsule format: Choose a capsule shell that is widely accepted, well-characterized, and compatible with your sealing foil and coffee chemistry.

Control environmental parameters: Temperature and relative humidity in the production room influence coffee behavior, static, powder flow, and sealing.

Degas coffee properly: After roasting, coffee emits CO₂. Adequate degassing time before filling reduces interference with sealing and pressure inside the capsule.

Test small runs: Before full-scale production, run test batches to validate dose settings, gas purge parameters, foil adhesion, and shelf stability.

Maintain consistent powder properties: Use sieving, deagglomeration, and blending tools to deliver uniform particle size and moisture content.

Balance gas flow and purge time: Overpurging wastes nitrogen and may disturb powder; underpurging risk oxidation.

Monitor and tune servo parameters: Slight adjustments to auger acceleration, deceleration, and dwell times can optimize flow stability.

Plan for spare tooling: Keep extra molds, sealing dies, and nozzles on hand so format changes are not held up by tooling issues.

Train personnel: Operators should understand mechanical, pneumatic, and control aspects of the system, enabling faster troubleshooting.

Implement regular audits and preventive maintenance: Scheduled checks prevent surprises and maintain uptime.

Challenges & Mitigation Strategies

While a coffee capsule filling machine brings many benefits, it also has potential challenges. Below are common ones and mitigation ideas.

| Challenge | Potential Impact | Mitigation Strategy |

|---|---|---|

| Inconsistent powder flow (bridging, clogging) | Fill variation, stoppages | Vibratory aids, anti-static measures, proper hopper design |

| Foil seal failures or leaks | Product returns, shelf-life issues | Clean sealing surfaces, optimize temperature, reject inspection |

| High scrap or rejects | Material cost, lower yield | Tight QC, frequent calibration, proper operator training |

| Gas leakage or overuse | Running cost, waste | Leak testing, efficient regulators, proper piping |

| Format changeover delays | Downtime, labor cost | Quick-change tooling, layout planning |

| Component wear or breakdowns | Unplanned downtime | Preventive maintenance, spare parts program |

| Environmental sensitivity | Variation in humidity or temperature | Climate control in facility, preconditioning of materials |

| Scaling beyond single-lane | Throughput limitations | Plan modular scaling, multi-lane upgrade path |

With careful planning, many of these challenges can be anticipated and mitigated early.

Future Trends & Innovation Directions

Looking ahead, the domain of capsule filling machines is evolving. Some anticipated and emerging trends include:

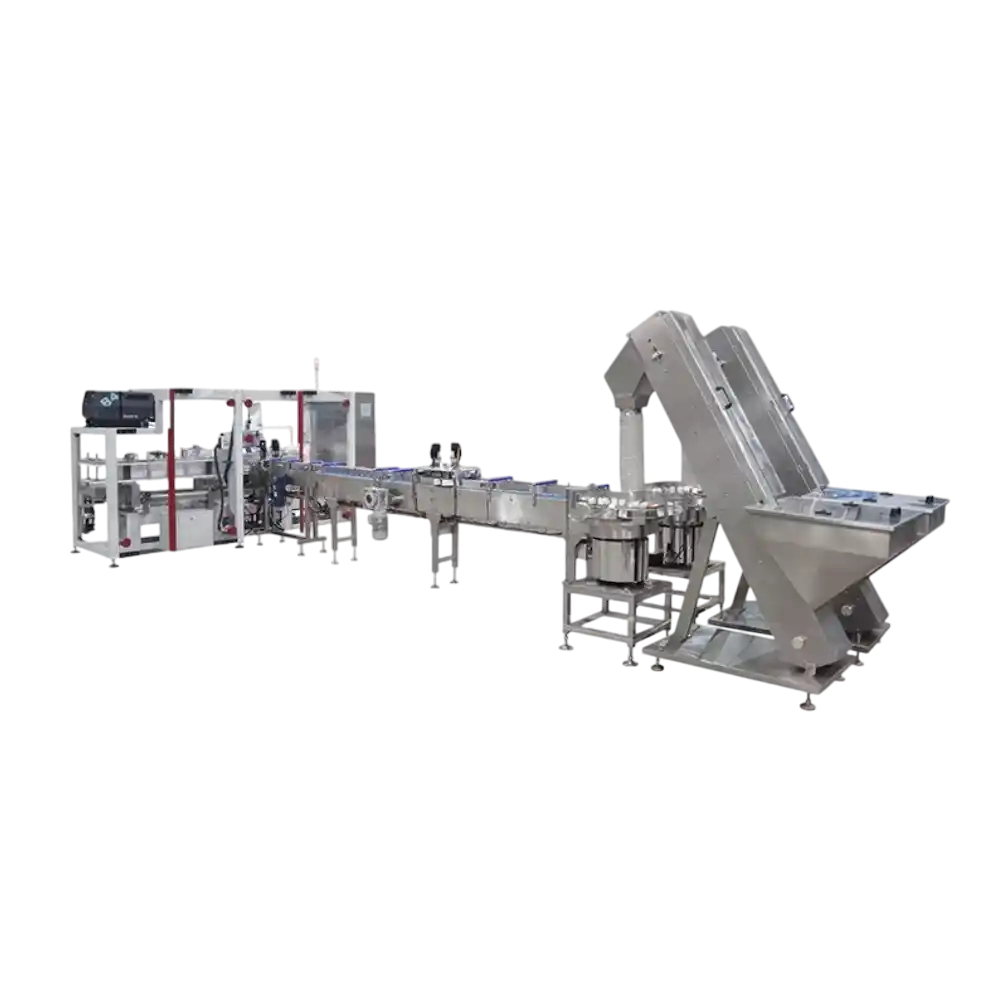

Multi-lane, high-throughput machines: For brands scaling to tens of thousands per hour, multi-lane systems (e.g. 3-lane, 6-lane) offer arithmetic scaling.

Smart, predictive maintenance: Integration of sensors, IoT, and predictive analytics to monitor wear, vibration, and performance.

Adaptive dosing: Real-time feedback loops adjusting servo dosing in response to weight drift or environmental changes.

Minimal-foil / sustainable sealing materials: Use of thinner films, biodegradable foils, or alternative sealing technologies to reduce material usage.

Alternative capsule formats: Adapting machines for compostable, bio-based shells or non-traditional shapes.

Integrated downstream packaging: Seamless coupling of capsule filling lines into boxing, shrink-wrapping, or palletization modules.

Modular upgrade paths: Designing filling machines that can be upgraded to multi-lane or higher speed without full replacement.

Energy recovery and efficiency: Heat reuse, gas recapture, and more efficient sealing systems.

Zero-waste designs: Closed-loop systems for dust, coffee fines, and foil waste.

Brands and engineers that keep an eye on these innovations can future-proof their capsule production operations.

Advanced Process Optimization

1. Powder Flow Dynamics

Achieving stable powder flow remains one of the most technical challenges in capsule filling. Ground coffee behaves as a semi-cohesive granular material—its flow properties depend on roast degree, oil content, grind size, and humidity. A coffee capsule filling machine that can handle diverse blends must have adaptable mechanisms.

Advanced designs often integrate vibration-assisted hoppers, fluidization aids, or coaxial augers that maintain uniform density of powder. These reduce “rat-holing” and “bridging,” where powder sticks to hopper walls and disrupts feed consistency.

Another crucial component is hopper geometry. A conical or steeper hopper angle ensures gravity-assisted flow, and a properly designed agitator prevents compaction at the auger inlet. Servo-controlled augers can vary rotational speed and acceleration curve to compensate for powder compaction changes between roast levels.

2. Adaptive Control Systems

Modern PLCs and motion controllers enable closed-loop feedback: weight sensors at capsule exit points provide real-time data to adjust auger rotation or dosing duration dynamically. This adaptive dosing maintains consistent weight even as environmental factors fluctuate.

Advanced software may log every cycle’s data for traceability—useful in quality audits and compliance documentation. Operators can visualize trends in weight deviation, reject rates, or gas pressure stability through dashboards.

3. Nitrogen Efficiency and Gas Flow Control

Nitrogen flushing improves shelf life but can also become costly. Optimizing flow rate and purge timing can save substantial operational expenses. Smart valves and proportional regulators linked to machine PLCs adjust gas flow precisely during capsule residence time.

Innovations such as micro-flush nozzles, turbulent flow diffusers, or gas recovery loops help reduce nitrogen use by up to 40%. Efficient systems deliver inert gas only when the capsule is under the nozzle, not continuously.

4. Seal Integrity and Quality Validation

Sealing consistency determines consumer experience and shelf life. Excess heat can cause delamination or melting, while insufficient heat yields leaks. Temperature mapping across the sealing die surface ensures even thermal distribution.

Some advanced coffee capsule filling machines include vision inspection cameras that check every capsule’s seal quality, detecting wrinkles, voids, or misaligned foils. These automatic rejection systems raise reliability and minimize manual inspection.

Additionally, periodic burst testing—pressurizing sealed capsules until failure—quantifies seal strength, helping adjust pressure and dwell time for optimal results.

5. Data Logging and Predictive Analytics

Integration of IoT sensors enables predictive maintenance. By collecting vibration, current draw, and cycle timing data, the system can alert operators before mechanical parts wear out. This minimizes unplanned downtime and supports continuous production.

Data analytics can correlate environmental parameters (temperature, humidity) with filling accuracy or reject rate, helping refine process windows. Over time, this knowledge base improves both machine performance and coffee quality consistency.

Integration With Upstream and Downstream Systems

1. Roasting, Grinding, and Degassing Coordination

A coffee capsule filling machine operates downstream of roasting and grinding. The coordination between these stages is critical. Roasted beans emit CO₂; if filled too early, gas expansion can rupture capsule seals. Therefore, the degassing time must be balanced — typically 24 to 72 hours depending on roast profile.

Integrating the filling schedule with roasting logs ensures that only fully degassed batches enter the hopper. Some facilities implement silo-based degassing with nitrogen blankets, feeding directly to the filling line.

Grind size also matters. Espresso grind, typically 250–350 µm, provides correct extraction in capsules. However, too fine a grind leads to poor flow and compaction; too coarse reduces taste intensity. Adjusting the grinder and validating particle distribution ensures compatibility with the dosing auger.

2. Upstream Feeding Automation

For higher throughput, automatic conveying from the grinder or storage silo to the capsule filler eliminates manual intervention. Systems using vacuum transfer lines, metal detectors, and inline sieves ensure purity and prevent foreign matter contamination.

3. Downstream Packaging Systems

Once capsules are sealed, they often move directly to secondary packaging:

Counting and sorting systems group capsules by fixed quantity.

Automatic cartoning lines insert capsules into branded boxes.

Shrink-wrapping and labeling systems apply barcodes and freshness dates.

Carton sealing and palletizing prepare finished goods for shipment.

The coffee capsule filling machine’s discharge conveyor should synchronize seamlessly with these downstream systems. Communication via Ethernet/IP or Modbus between controllers allows line-wide coordination and fault recovery.

4. Nitrogen-Integrated Conveyance

For premium capsule brands, even the transfer from filler to packaging is done in a low-oxygen atmosphere. Nitrogen-filled tunnels or enclosed conveyors preserve oxygen levels below 2%, maintaining ultimate freshness until final sealing of retail cartons.

5. Enterprise Resource Planning (ERP) Connectivity

Larger operations integrate machine data into ERP or MES (Manufacturing Execution Systems) for traceability. Each batch’s parameters—blend, roast date, fill weight, operator ID, and lot number—are logged automatically. This integration simplifies audits, recalls, and inventory control.

Economic and Financial Considerations

1. Investment and Return on Investment (ROI)

While the initial investment in a coffee capsule filling machine can be significant, payback often occurs within months if production volume is steady. Let’s consider simplified calculations:

Machine cost: $20,000–$60,000 for a single-lane unit

Throughput: ~3,000 capsules/hour

Operating 8 hours/day: 24,000 capsules/day

Gross margin per capsule: $0.10

Daily gross margin: $2,400

Payback time: 25 working days (~1 month)

This is a simplistic example, but it illustrates how capsule filling can quickly become profitable once volume stabilizes.

2. Operating Costs

Key cost components include:

Electricity and compressed air

Nitrogen gas consumption

Capsule shells and foils

Coffee raw material

Labor and maintenance

Nitrogen and foil optimization can reduce consumable costs by 10–20%. Regular maintenance prevents expensive downtime.

3. Labor Efficiency

One trained operator can manage one or two machines, performing loading, inspection, and packaging tasks. Compared to manual filling and sealing, automation can cut labor hours by 70–80%.

4. Flexibility vs. Capital Cost

Compact single-lane machines cost less and allow rapid product changes. Multi-lane machines achieve higher throughput but require higher investment and more complex setup. Businesses should evaluate their expected production scale before deciding.

5. Space and Infrastructure

The small footprint (~1 m²) means low facility requirements. Nevertheless, ensuring stable electricity, compressed air, and humidity control adds minor capital costs. Many small roasters adapt existing spaces without new construction.

Regulatory and Food Safety Compliance

1. Hygiene and Materials

Because the product is food-grade, compliance with standards like FDA (for U.S.), EU Regulation 1935/2004, or local equivalents is essential. All contact surfaces in a coffee capsule filling machine must be stainless steel or food-safe plastics.

Regular cleaning protocols and verification of non-toxic lubricants, seals, and adhesives are mandatory.

2. Hazard Analysis and Critical Control Points (HACCP)

Facilities operating capsule lines should maintain a HACCP plan identifying potential contamination points—coffee powder, capsule shells, sealing foils, and gas lines. Preventive controls and sanitation schedules reduce risks.

3. Traceability and Batch Coding

Each batch must be traceable to raw materials and machine settings. Integrating inkjet or laser coding to print date, lot number, or origin code on the foil enhances traceability and consumer trust.

4. Nitrogen and Compressed Air Quality

Gases in contact with coffee must meet EIGA or ISO 8573 standards for food use. Filtration, dryness, and purity checks should be routine.

5. Operator Safety

Machines should feature safety interlocks, guards, and emergency stops. Training in lockout-tagout (LOTO) procedures ensures maintenance safety. CE-marked machines already comply with mechanical and electrical safety norms.

Real-World Case Scenarios

Case 1: Boutique Roaster Expanding to Capsules

A boutique coffee roaster producing 200 kg of beans per week decided to enter the capsule market. By acquiring a compact coffee capsule filling machine, they could produce 3,000 capsules per hour. They branded their capsules under a new name, targeting local offices and e-commerce customers. Within three months, capsule sales equaled their bagged coffee sales.

Key outcomes:

Reduced dependence on external co-packers

Improved freshness due to on-site filling

Achieved full ROI in 10 weeks

Case 2: Contract Packaging Service Provider

A packaging service invested in two filling machines and offered small-batch capsule filling for other roasters. They could run different blends daily thanks to quick-change molds. Their business model was “fill and seal as a service,” handling 50,000 capsules per day for multiple clients.

Benefits:

Low overhead compared to large automated factories

High flexibility

Strong client retention due to fast turnaround

Case 3: R&D Lab Testing Sustainable Capsules

An R&D department of a coffee chain used a capsule filling machine to test biodegradable PLA capsules. Adjustments in sealing temperature and dwell time were necessary, but successful sealing without deformation proved feasible. The machine’s modular mold allowed swapping between aluminum and PLA capsules quickly.

Results:

Verified seal compatibility for compostable materials

Enabled pilot runs before full-scale launch

Supported sustainability research

Case 4: Large-Scale Producer Using Multi-Lane Upgrade

A large manufacturer running six single-lane units transitioned to a custom-built multi-lane coffee capsule filling machine. Output rose from 18,000 to 60,000 capsules per hour. PLC synchronization allowed centralized monitoring of all lanes, dramatically improving efficiency.

Practical Engineering Deep Dive

Thermal Analysis of Sealing

Heat transfer from the sealing head to the foil must reach a specific threshold (usually around 180–220 °C) for aluminum-laminate foils. Uniform heat distribution avoids localized overheating. Some machines use PID-controlled cartridge heaters embedded in the sealing plate to maintain precise temperature.

Vibration and Damping

Because powder filling relies on mechanical movement, vibration damping in the base frame is critical. Over-vibration causes dosing errors. Proper leveling, base anchoring, and isolation pads enhance accuracy and longevity.

Pneumatic Control Logic

Pneumatics operate capsule ejection, foil cutting, and pick-and-place arms. Stable pressure and filtered air ensure smooth motion. A pressure regulator with fine adjustment (0.6–0.8 MPa) balances force and cycle speed. Solenoid valves controlled by PLC outputs coordinate timing.

Electrical & Motion Synchronization

Servo drives control the auger screw and sometimes the sealing head motion. Encoders provide position feedback. Synchronization between auger rotation and capsule dwell time prevents spillage. Cable routing, shielding, and grounding are critical to avoid electromagnetic interference that could disturb sensors.

Preventive Maintenance Schedules

| Component | Frequency | Action |

|---|---|---|

| Auger screw & hopper | Daily | Clean, inspect for buildup |

| Sealing die | Daily | Wipe with food-safe cloth |

| Belts & couplings | Weekly | Check tension and wear |

| Air filters | Monthly | Replace if pressure drop >10% |

| PLC / electrical | Quarterly | Backup programs, inspect wiring |

| Bearings & motors | Annually | Lubricate, check vibration |

Following such schedules prolongs life and keeps consistent performance.

Quality Metrics and Statistical Process Control (SPC)

Implementing SPC provides real-time assurance of capsule consistency.

Key metrics:

Net weight per capsule (mean and standard deviation)

Oxygen residual (%)

Seal strength (N)

Reject ratio (%)

Foil alignment error (mm)

Control charts can visualize these parameters, allowing quick detection of drift. For example, if standard deviation of fill weight exceeds 0.2 g, corrective action is triggered.

Energy Optimization and Noise Reduction

Modern designs incorporate inverter-driven motors and standby power modes. A properly tuned coffee capsule filling machine consumes only about 2.5–3.5 kW, significantly less than older pneumatic-heavy designs. Noise levels can be kept below 75 dB(A) with insulated covers and smooth pneumatics.

For operators working long hours, reduced noise improves comfort and compliance with occupational safety regulations.

Supply Chain and Spare Parts Management

Having a structured supply chain for spare parts ensures business continuity. Recommended inventory:

Sealing foils for at least one month of production

Capsule shells from at least two suppliers to mitigate stock risk

Spare auger assemblies, belts, sensors

Calibrated scales for weight validation

Vendor qualification and periodic audits guarantee that consumables remain food-grade and dimensionally accurate.

Environmental Impact & Lifecycle Analysis

An often-overlooked area is the total environmental footprint. Lifecycle analysis (LCA) considers energy use, raw material sourcing, waste management, and end-of-life disposal.

Energy Use

Per thousand capsules, typical energy consumption ranges from 1.5 to 2 kWh. Optimizing cycle speed, insulation, and heater efficiency can lower this by 10–15%.

Waste Stream

Foil waste: can be recycled if collected cleanly.

Coffee dust: organic waste suitable for composting.

Defective capsules: can be separated and ground coffee reclaimed before recycling shells.

Carbon Footprint Reduction Strategies

Use renewable electricity where available.

Implement energy recovery from sealing heat.

Partner with capsule material suppliers using recycled or bio-based plastics.

Adopt lighter foil gauges without compromising seal integrity.

Future Opportunities: Automation and AI

AI-Driven Quality Control

Computer vision combined with AI algorithms can detect defects more accurately than manual inspection. Systems trained on image datasets learn to identify subtle foil wrinkles or fill anomalies, increasing quality without adding labor.

Predictive Maintenance with Machine Learning

Using sensors and cloud analytics, the machine can predict bearing wear or auger misalignment before failure. This approach shifts maintenance from reactive to proactive.

Robotics Integration

Collaborative robots (cobots) can handle capsule loading, carton packing, and pallet stacking. Their integration with the coffee capsule filling machine boosts automation without large infrastructure changes.

Smart Production Dashboards

Cloud-connected dashboards allow remote monitoring: managers can view production statistics, OEE (Overall Equipment Effectiveness), and alerts in real time from any device.

Sustainability Data Tracking

IoT integration can track nitrogen consumption, power use, and foil waste, calculating sustainability KPIs automatically for ESG reporting.

Extended Applications Beyond Coffee

While designed for coffee, the same technology can handle various powdered or granular products:

Tea or herbal blends (ground, instant, or powder)

Hot chocolate or cocoa powders

Functional supplements (vitamins, collagen, adaptogens)

Instant drink mixes

Milk powder or flavored creamers

This versatility broadens potential revenue streams. By changing recipes and possibly adjusting sealing profiles, one machine can support multiple product lines.

Training and Human Factors

Operator Skill Development

Although automation reduces manual labor, human expertise remains vital. Operators must understand:

Parameter adjustments (dosing, sealing temp)

Basic troubleshooting and calibration

Cleaning and sanitation protocols

Data recording and quality documentation

Training programs or certification help standardize competence across shifts.

Ergonomic Design

Well-designed HMIs with intuitive menus, color-coded alerts, and adjustable screen height improve operator comfort. Easy-reach access to hoppers and foil rolls reduces strain injuries.

Documentation and SOPs

Standard Operating Procedures (SOPs) must be clear, covering start-up, shutdown, cleaning, and maintenance. Illustrated guides help non-native speakers or new hires learn quickly.

Comparative Overview: Manual vs. Semi-Automatic vs. Automatic

| Parameter | Manual Filling | Semi-Automatic | Fully Automatic |

|---|---|---|---|

| Output | 200–500 caps/h | 1,000–2,000 caps/h | 3,000–10,000 caps/h |

| Consistency | Low | Medium | High |

| Labor requirement | 2–4 operators | 1–2 operators | 1 operator |

| Accuracy | ±1 g | ±0.5 g | ±0.2 g |

| Investment | Low | Medium | Higher |

| ROI time | Long | Moderate | Short |

| Best for | Startups | Small roasters | Professional brands |

This comparison clarifies why the fully automatic coffee capsule filling machine represents the professional standard.

Comprehensive Final Overview

The coffee capsule market continues to grow globally as consumers demand convenience without sacrificing quality. In this ecosystem, the coffee capsule filling machine is not just an industrial device—it is the bridge between craftsmanship and scalability.

Through precision engineering, advanced control systems, and modular design, these machines empower small and large producers alike to maintain aroma integrity, deliver consistency, and build brands that stand for freshness and innovation.

The decision to invest in such technology brings multiple benefits:

Autonomy – control your production schedule and quality.

Efficiency – save on outsourcing and logistics.

Scalability – expand production easily as sales grow.

Innovation – experiment with blends, origins, and sustainable materials.

Sustainability – reduce waste, optimize energy, and adopt eco-friendly capsules.

With careful operation, training, and preventive maintenance, a coffee capsule filling machine can run for years with minimal downtime, generating consistent output and solid returns.

In the next decade, advancements in sensors, AI, and sustainability will further elevate these systems—bringing smarter, greener, and more efficient solutions for coffee producers worldwide. Whether you are a craft roaster or an industrial supplier, mastering capsule production through a well-designed filling machine is the key to thriving in the modern single-serve coffee era.