| Parameter | Value |

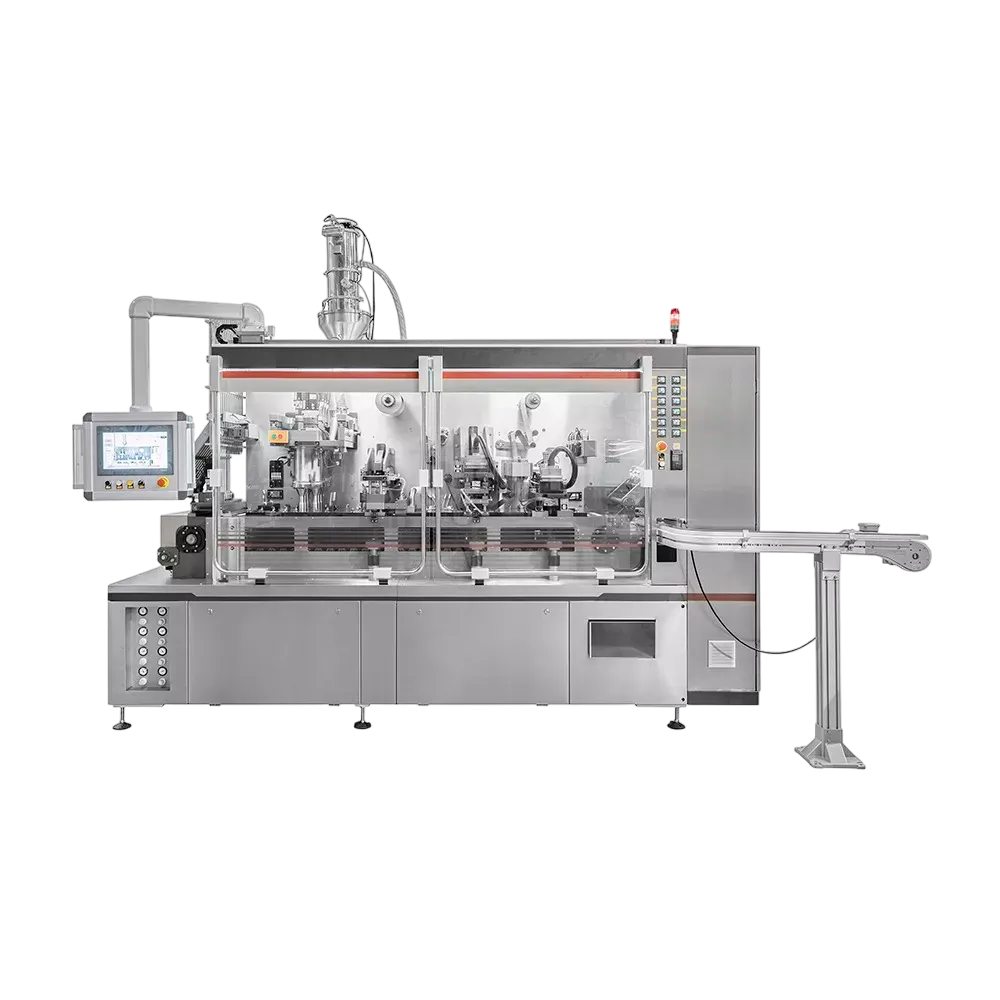

| Model | DTC2 two-lane coffee capsule filling & sealing machine |

| Applicable materials | Fresh ground coffee, instant coffee, tea powders, milk powders, other fine powders |

| Output | 90–100 capsules/min per lane (total ~6,000 capsules/hour) |

| Filling system | Auger filler driven by servo motor |

| Filling accuracy | ±0.15 g |

| Filling range | 0–20 g |

| Sealing method | Roll film cutting and heat sealing |

| Hopper capacity | 12 L |

| Power | 7.5 kW |

| Voltage | 3-phase, 220/380 V, 50/60 Hz |

| Compressed air consumption | ≥ 300 L/min |

| Compressed air supply requirement | Dry air ≥ 6 bar |

| Nitrogen usage | ≥ 200 L/min (optional, for inert sealing) |

| Machine weight | ~2,000 kg |

| Dimensions (L × W × H) | 5,500 × 2,010 × 2,700 mm |

| Certification | CE, ISO 9001, UL |

| Contact parts | Food-grade stainless steel (AISI 304) |

Revolutionizing Coffee Production: The Advantages, Applications, and Technical Insights of the DTC-2 Coffee Capsule Filling Machine

Introduction

Coffee shops need to be spot-on these days, so machines that deliver consistent quality become essential. Businesses aiming for growth without breaking the bank should consider smart equipment choices. Coffee capsule fillers are key to how we get our quick cups these days. The DTC-2 series stands out – it’s built for speed, works consistently, moreover adapts easily to different needs.

Ever wondered how those little coffee pods are made? This piece explores the machines that fill them – what makes them tick, where they’re used, plus exactly how they work. It also covers smart ways to run one, alongside a look at what’s coming next. Businesses aiming for top spot in coffee pod production often choose models like the DTC-2.

1. The Role of a Coffee Capsule Filling Machine in Modern Production

1.1 Transition from Traditional Packaging to Capsule Systems

These days, folks want great coffee that fits their busy lives. It’s a big change from how things were just twenty years ago. Now everyone wants those little coffee pods, so companies had to change how they do things. Instead of big bags of coffee, making these pods requires:

- Getting the amount just right – it keeps tastes steady while also managing expenses

- Keeps things clean to maintain flavor – also ensures a fresh experience

- Keeping contents fresh – a tight seal is key

- It handles a lot, growing easily when needed.

The key to this change? A machine expertly dispensing ground coffee – even tea or milk powder – into little pods, then closing them tight.

1.2 Why Select a Capsule Filling Machine Over Manual Methods?

Small batches? Handwork might do. However, once you need more than a little coffee – forget it. A proper capsule filler delivers:

- Machines consistently deliver the correct amount of medicine – give or take a tiny fraction of a gram. They’re remarkably precise.

- These days, equipment churns out a whole lot of capsules – we’re talking tens of thousands every sixty minutes.

- Automation cuts down on hand work while also lessening mistakes people make.

- Keeping things sanitary – built to be easily cleaned – lowers chances of unwanted germs.

- Machines often handle various capsule types, also switching between them isn’t difficult.

- These machines fit seamlessly into production lines – handling capsules, sealing them, boxing things up, even creating cartons.

Because of the benefits, a lot of modern coffee companies now use capsule filling machines – either on their own or built into existing systems – as key parts of how they make things.

2. DTC-2 Coffee Capsule Filling Machine: Key Features & Capabilities

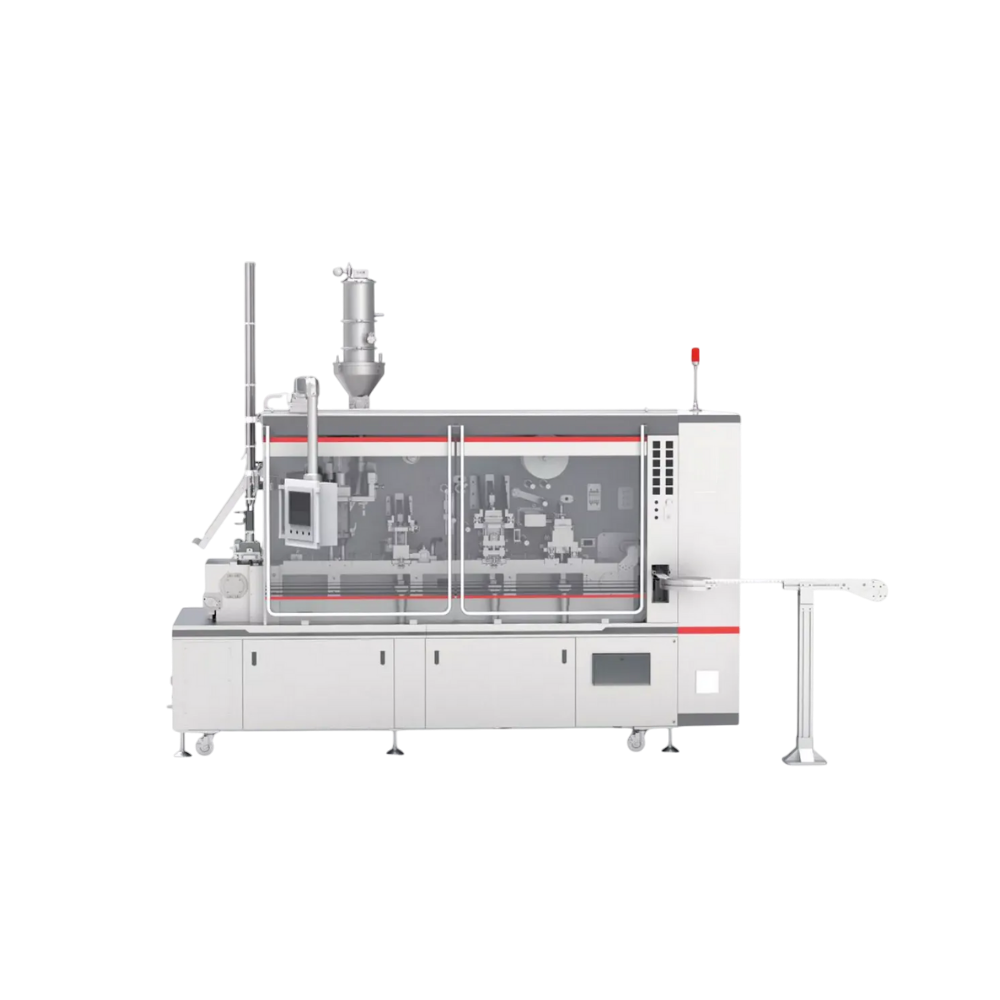

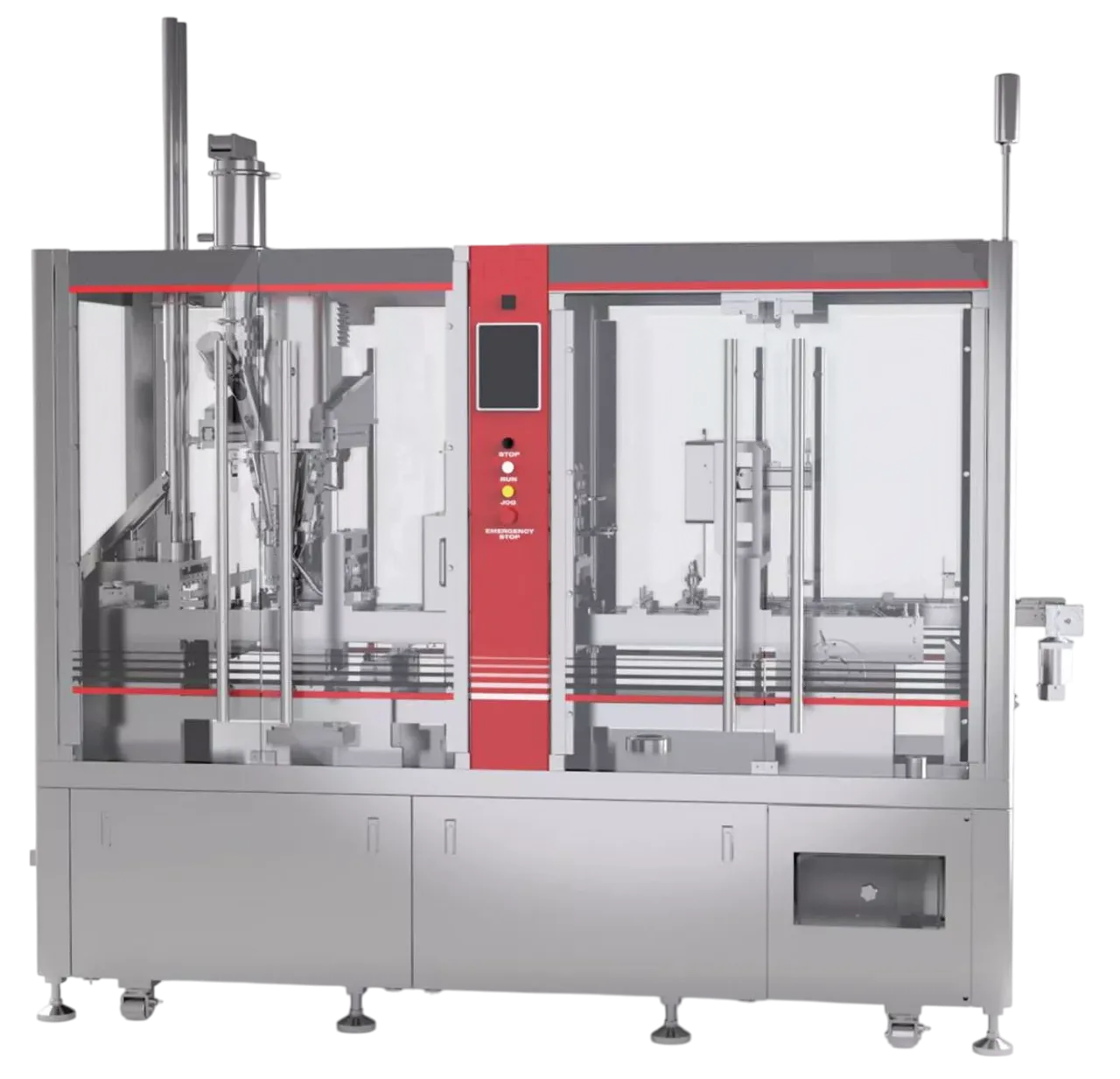

Here’s how the DTC-2 line – built using those specs – really shines when it comes to making capsules. It’s about what it does, alongside how it works.

2.1 Production Capacity and Speed

- The machine churns out roughly 6,000 capsules each hour – that works to about 90 to 100 capsules a minute.

- A sensible pace lets a typical factory keep making enough product to satisfy customers

- This machine handles enough volume for coffee companies growing beyond small batches – it’s built for those moving into larger production.

2.2 Filling Mechanism

- A servo motor powers the machine’s auger, dispensing product consistently. Because it monitors how much is released using a feedback loop, each dose remains remarkably accurate from start to finish.

- You can tweak it precisely, get consistent results each time, moreover, it works well with varying amounts – whether you need a tiny bit or up to twenty grams.

- The system consistently fills within 0.15 grams – a small margin vital to both keeping costs down also ensuring top quality.

2.3 Sealing Process

- A roll of foil or laminate feeds through, gets trimmed to fit, then seals shut around each capsule. It’s a neat system – less waste, simpler stocking.

- To keep its scent fresh, the package needs a tight seal – one that blocks air, keeps out dampness, moreover shields from anything spoiling it.

2.4 Material and Construction Standards

- The components touching coffee – grounds or pods – are built using a special stainless steel. It won’t rust, cleans easily, moreover meets health guidelines for food.

- This gear adheres to CE, ISO 9001, likewise UL guidelines – meaning it satisfies vital global benchmarks for both safety but also build quality.

2.5 Power & Utilities

- This equipment needs a hefty power supply – 7.5 kilowatts, running on three phases. It’s designed to work worldwide with either 220 or 380 volts at standard frequencies of 50 or 60 Hertz, which is what you’d expect in most factories.

- You’ll need an air supply delivering at least 300 liters per minute, with a pressure of 6 bar or higher – it must be dry, also filtered.

- Frequently, air powers capsules’ movements, operates mechanisms, or manages control systems via compressed gas.

- The machine uses at least 200 liters of nitrogen per minute when clearing out gases – a feature some models have to keep products fresh longer.

- The hopper holds 12 liters of powder. Consequently, that’s the amount you can use prior to needing a refresh.

2.6 Physical Dimensions & Weight

- It tips the scales around 2,000 kilograms – a testament to its solid construction. Think hefty frames, vibration control, moreover durable components.

- It measures 5.5 meters long, 2.01 meters wide, and 2.7 meters high. Because it’s so big, think about space needs for setup, getting to it, upkeep, also repairs.

2.7 Tolerance & Flexibility

- You can fill capsules with between zero and twenty grams. Consequently, this allows for diverse options – from tiny espresso shots to bigger coffee blends, even tea powders.

- This device handles various products – different coffee roasts, flavors, even decaf – because its settings change to work with each one.

2.8 Environmental and Operational Advantages

- Though substantial, the device is built to avoid excess – it uses materials wisely, creates little scrap, yet remains surprisingly contained.

- It works on autopilot, so less dust gets loose, things don’t mix when they shouldn’t, also you waste far fewer materials.

3. Manufacturing Workflow & Integration

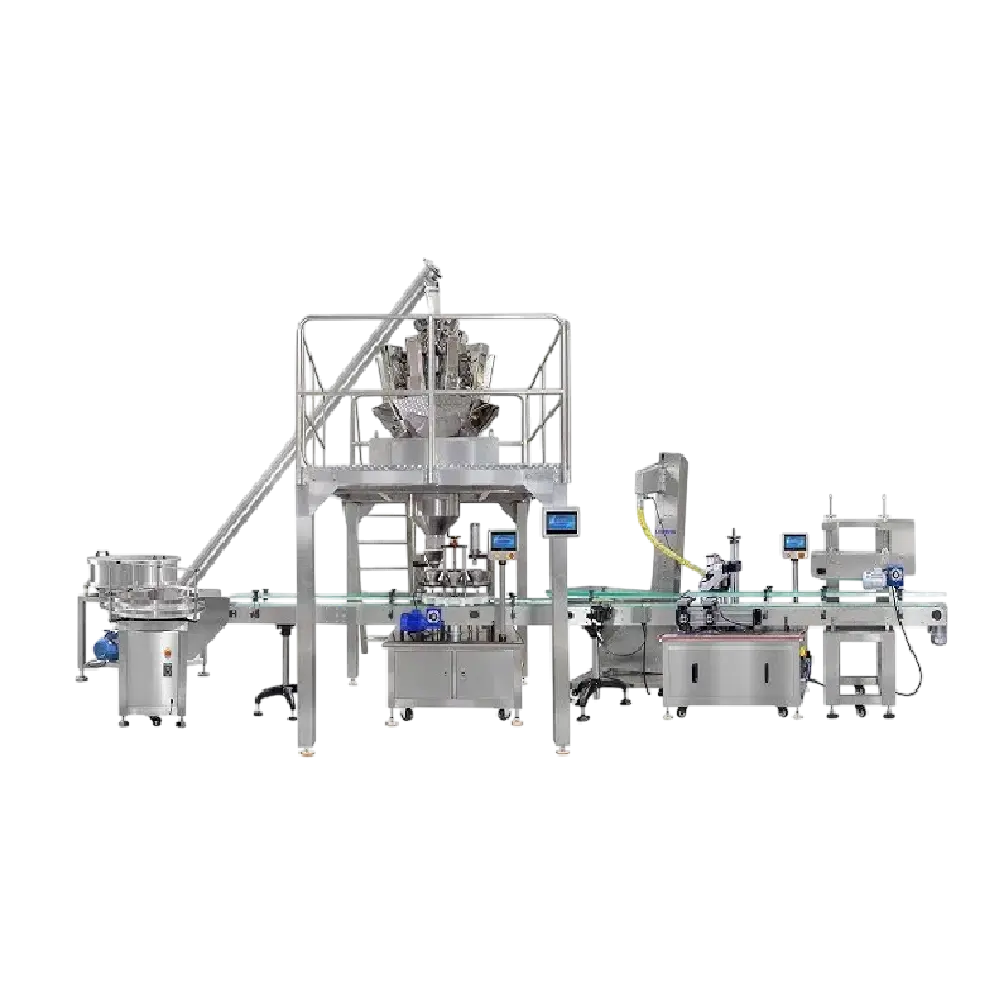

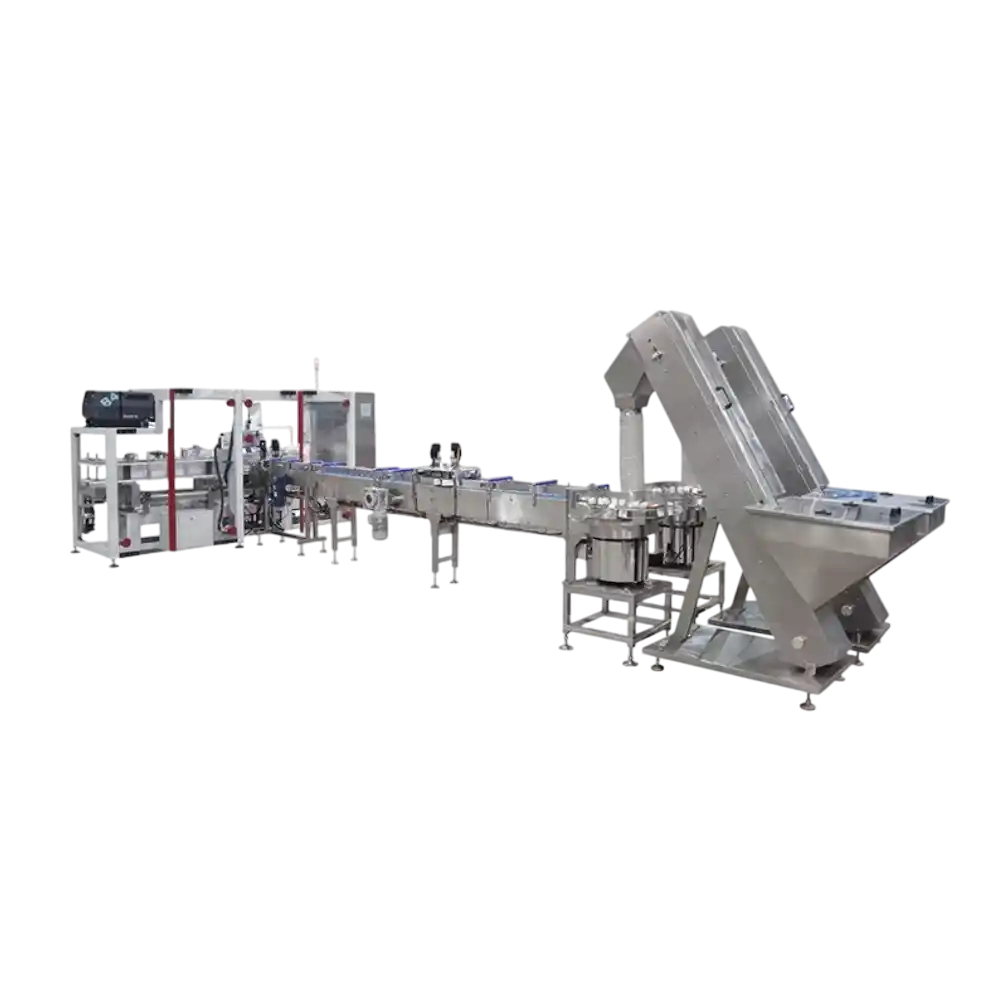

Typically, a powerful coffee capsule filler – consider the DTC-2 – isn’t a standalone piece of equipment. It usually works within a complete production system. Knowing its connection to what happens before also after filling proves vital.

3.1 Upstream Processes

- Capsule Feeding & Sorting

- Capsules need a steady flow into the machine – think rhythmic delivery. We get that using vibrating chutes, robotic arms carefully positioning each one, or rotating turntables.

- Capsule Orientation / Pre-conditioning

- To keep them fresh – or seal better – certain capsules need a little prep work beforehand, like removing air with a vacuum or flushing with nitrogen.

- Powder Pre-treatment / Blending

- To get a smooth, steady stream into the machine, the coffee – or whatever powder is used – needs to be thoroughly mixed, maybe even dried or sifted first.

- To keep things flowing smoothly into the filling process, a holding bin – or one that measures how much is fed – can be positioned beforehand.

3.2 Typical In-Line Steps (Around the Filling Machine)

- The device seizes capsules, then places each one neatly beneath where they get filled.

- A motorized screw carefully measures out each scoop of powder.

- To get a smooth surface, certain machines gently even out or compress the ground coffee before closing.

- A film roll gets put on, then warmth fuses it shut.

- Checks confirm proper cooling; also, they inspect seals for flaws.

- To cut down on leftover oxygen, an optional step introduces a harmless gas to sweep things clean.

- Once made, capsules move onto belts, into containers, or toward further packing.

3.3 Downstream Processes

- Dates, lot codes, likewise company logos can appear either printed on items or pressed into their surface.

- Capsule groups get boxed up by automatic cartoners.

- Items get a final touch – shrink-wrapped, boxed up, or stacked on pallets – before they ship.

If the DTC-2 breaks down, or even sputters, everything that follows gets held up – it’s vital it keeps running smoothly to maintain production.

4. Advantages & Commercial Benefits of the DTC-2 Coffee Capsule Filling Machine

When choosing equipment, people consider more than just what it can do; they weigh its long-term expenses, possible income gains, alongside whether it keeps things running smoothly.

4.1 High Throughput Without Compromising Quality

Running between ninety to one hundred capsules a minute keeps production steady enough for business – yet still gets the dosage right. This equilibrium matters when companies release several items or forecast yearly volumes.

4.2 Versatility Across formulations & SKUs

With a fill weight from zero to twenty grams, one machine handles everything – little espresso shots, longer lungos, spice-infused pods, or maybe even tea. It cuts down on needing lots of different equipment while letting companies switch production easily.

4.3 Consistent Dose Accuracy

Consistent fill weights – staying near the target, give or take a little – mean products taste right while keeping expenses down. Too little product? Customers notice. Too much? Profits shrink.

4.4 Modular Design, Maintenance & Cleaning

Built tough, this design simplifies upkeep – you get to vital pieces fast, meaning less lost time. Because its parts touching products are stainless steel, cleaning is simple, keeping things sanitary.

4.5 Integration Ready & Scalable

The DTC-2 works well within existing manufacturing systems thanks to its typical connections for both incoming materials also outgoing products. Consequently, expanding operations becomes straightforward – just incorporate more lines or equipment as needed.

4.6 Regulatory & Safety Compliance

Meeting CE, ISO 9001, or UL requirements smooths the way for use in places with strict rules – like Europe, North America, also elsewhere.

4.7 Extended Shelf Life Through Inert Gas Purging

It keeps things fresh by managing nitrogen use – sometimes including a gas flush to displace oxygen within containers, thereby safeguarding aromas longer.

5. Operational Best Practices & Optimization Tips

Getting a coffee capsule filler isn’t enough to win – you also need things running smoothly. Setting it up right, tweaking it just so, then keeping it in good shape matters most if you want top results. Here’s how we suggest doing that:

5.1 Site Preparation & Installation

- A solid, even floor is vital. The machine weighs around 2,000 kilograms, so the surface needs to handle that weight without wobbling.

- You’ll find everything needed here: three-phase electricity, a supply of dry compressed air, connections for inert gases, alongside reliable electrical grounding.

- Keep air moving, pull away dust: Less dust floating around where powders are handled means simpler upkeep, cleaner goods.

5.2 Calibration & Validation

- Double-check the servo-driven screw feed using sample runs alongside known standards; ensure it consistently dispenses material within a tight range – no more than plus or minus 0.15 grams.

- Regularly examine operations, noting any changes, so shifts become apparent.

- When making several products at once, double-check the dosage for each one prior to starting production.

5.3 Start-Up & Changeover Routines

- Let the machine ease into operation; initial runs without a load will help settle its warmth.

- When you shift to a new recipe, be sure to thoroughly clean everything first – hoppers, the auger, the works. This keeps things running smoothly.

- To speed things up, stick with established formulas for typical dosages.

5.4 Preventive Maintenance

- Frequently check over auger shafts, likewise examine bearings, seals, also servo feedback systems.

- Keep an eye on heaters likewise sealers – look for fading or shifting.

- Swap out parts that wear down – like seals, rings, or guide strips – on a regular schedule.

- Keep records of cleaning – trace everything back to guarantee safe food.

5.5 Quality Control & Inline Monitoring

- Look for missing product, too much, or unwanted stuff by adding a scale right after filling – or use an X-ray machine instead.

- Check packages are sealed correctly – a vacuum test is one way to do this.

- Track how much is made, when things break down, also what gets tossed, so we can constantly get better.

5.6 Continuous Training & Documentation

- Give staff handbooks detailing how to calibrate equipment, maintain cleanliness, then fix problems. Also offer instruction.

- Keep a record of how the device is set to cook, when it cleans itself, also any repairs or upkeep.

6. Potential Applications and Market Use Cases

6.1 Single-Origin Specialty Coffee Brands

Small-batch roasters aiming for peak taste rely on precise capsule machines – they deliver consistent portions while cutting down on grounds lost.

6.2 Contract Manufacturing & Private Labels

Companies making coffee for different brands can easily switch between products on a single DTC-2 machine, which gives them an advantage.

6.3 Startups & Pilot Programs

New coffee businesses experimenting with single-serve pods should start small – a machine such as the DTC-2 lets them gauge interest without a huge initial investment.

6.4 Tea, Supplement, & Powdered Drink Capsules

It doesn’t stop at coffee; this machine also handles tea, health shakes, even powdered drink mixes thanks to its adaptable design.

6.5 Research & Development Facilities

Labs might test fresh mixes alongside recipes using this device prior to large production runs.

7. Challenges & Considerations Before Deployment

Powerful tools come with their own set of headaches. Knowing what could go wrong helps things run more easily.

7.1 Capital Investment & ROI

Getting started requires a large upfront payment. Businesses need to predict how many capsules they’ll sell, improve profits, likewise estimate overall expenses if they want this investment to pay off.

7.2 Powder Flow Behavior

Good coffee presents a challenge – how easily it pours relies on how finely it’s ground, the air’s moisture, also how evenly sized the grains are. To get reliable results, manufacturers sometimes employ methods like drying with circulating air, or they mix in ingredients to prevent clumping.

7.3 Capsule Material Compatibility

Capsule shells – whether plastic, metal, or plant-based – sometimes need different heat, squeeze, or wrapping settings. Double-check they work well with the machine.

7.4 Consumables & Film Supply

Getting consistent sealing film, foil tops, also capsule shells matters a lot. A different supplier – or lower quality stuff – can mess things up.

7.5 Downtime Risk & Spare Parts

This equipment’s intricate design means even a small issue halts work. Therefore, keeping plenty of replacement components on hand – alongside skilled technicians – is vital.

7.6 Regulatory & Food Safety Compliance

Where a product is sold – whether in Europe, the States, or elsewhere – official checks might demand proof of origin, clean working practices, safe handling rules, alongside complete records.

8. Future Trends & Innovations in Capsule Filling Technology

Coffee pod tech is shifting. Here’s what’s new:

- More lanes – even a circular design – mean processing many items quickly. They handle four, six, or even greater volumes.

- Augers dispense material, yet learn as they go – tweaking their operation instantly to maintain accuracy.

- Working with earth-friendly packaging – films or pods that break down naturally.

- Tiny doses built right in: flavors or ingredients mixed into every capsule.

- See exactly what’s happening – flaws, how full things are, unwanted bits – using smart visual checks.

Though things get better, the way systems – like DTC-2 – are built, piece by piece, means they won’t become outdated quickly; instead, they’ll serve as a base for what comes next.

9. Sample Deployment Scenario

Let’s look at a real-world example – how a company could actually use a coffee capsule filling machine sold directly to consumers. Imagine this situation:

- Brand A is releasing a fresh set of coffee capsules – three varieties, specifically: Espresso, Lungo, alongside a flavored option.

- We aim to manufacture one million capsules each month.

- The DTC-2 churns out a hundred capsules each minute, which works to about six thousand an hour. With two shifts running sixteen hours daily for twenty-six workdays, production hits roughly 2.5 million capsules.

- Despite hiccups, breaks, also upkeep, there’s plenty of room to expand.

- Being able to adjust amounts across products keeps production costs down when mixing varied recipes.

The company streamlines output – from initial mixing through automatic delivery to final sealing – with a reliable capsule filler at its core. This setup allows for quick growth alongside demand.

10. Conclusion

For coffee companies switching to capsules, a good filling machine is key. These DTC-2 models strike a nice chord between speed, accuracy, adaptability, alongside durability. Businesses aiming for large volumes, reliable results, and long-term use will find this gear essential for modern capsule creation.

11. Maintenance Procedures and Machine Longevity

How long a coffee capsule filling machine runs relies on upkeep. Though built tough, regular checkups alongside careful handling really boost its lifespan.

11.1 Scheduled Maintenance Plan

Generally, keeping things running smoothly means a good plan covers:

- Each day, look over the bean hopper, where capsules are sealed, how capsules drop in, also the mixing chamber – clear out any old coffee grounds. Use a vacuum or cleaner designed for food equipment to do this.

- Each week, look at the servo motors – also the sensors. Ensure the auger spins without trouble; listen for any shaking.

- Each month, keep things running smoothly by greasing bearings, fine-tuning how much items weigh, likewise checking air valves for any escaping pressure.

- Each quarter, take off the safety shields. Then, thoroughly scrub inside – check that heat sensors alongside heaters create a tight seal.

Regular procedures ward off weariness in the machinery, minimize interruptions, also guarantee each capsule comes out with the same weight alongside a solid seal.

11.2 Spare Parts and Consumables Management

To keep things running smoothly, a good stock of replacement parts needs to have:

- Drill bits alongside waterproof barriers

- Servo motor couplings

- Movie film gets snipped, then heat presses shut the ends

- Devices gauging heat – temperature sensors – work alongside thermocouples

- Pneumatic O-rings and air valves

Keep enough vital parts on hand for half a year – that way, production keeps going when shipments get delayed. Store things such as film rolls and capsules where it’s cool alongside being dry, otherwise they might bend or soak up water.

11.3 Operator Training and Certification

A fancy gadget won’t do much good unless someone knows how to use it. Good training needs to cover:

- How to begin – or end – operations

- Tweaking settings – how much material, how fast it moves, heat level

- Emergency stop protocols

- Fixing everyday problems – sensors acting up, pods stuck, or warnings about air levels

- Keeping things clean – following the rules about it

Skilled staff cut mistakes while ensuring each item is made to the same high standard. Most plants check yearly that everyone receives updated training.

12. Quality Assurance in Capsule Production

Coffee capsule machines need robust checks to align with global benchmarks. These inspections encompass the whole process – how materials arrive through when boxes are sealed.

12.1 Incoming Raw Material Control

Great coffee begins with the beans. Make certain the roasted, ground coffee maintains a steady:

- Usually, things hold some water – between two to four percent

- Knowing how big the bits are helps keep things moving smoothly

- Keep coffee smelling its best; use freshly ground beans within a day

Also, check capsule coverings likewise film tops for flaws or size issues impacting how well they close.

12.2 In-Process Quality Checks

During filling operations:

- Check capsule weight frequently – perhaps every half hour.

- The system now notes how much stuff goes in, alongside heat levels, directly from the factory equipment’s computer.

- Check the seals – look for creases, gaps, or dirt.

- Check for leftover nitrogen – we need to be certain oxygen stays under 2%.

If things go off course, something shifts – the drill gets fine-tuned, or the closer is repositioned.

12.3 Final Product Validation

To be sure everything’s right before sending things out, a quick check involves picking items at random to confirm they meet standards

- Keep capsules whole; ensure they don’t spill

- Getting things named right, or written into code properly

- Even distribution – weight, ingredients – throughout.

- Get items boxed correctly, also verify how many boxes there are

Systems that check automatically help keep things uniform – they toss out capsules that aren’t quite right.

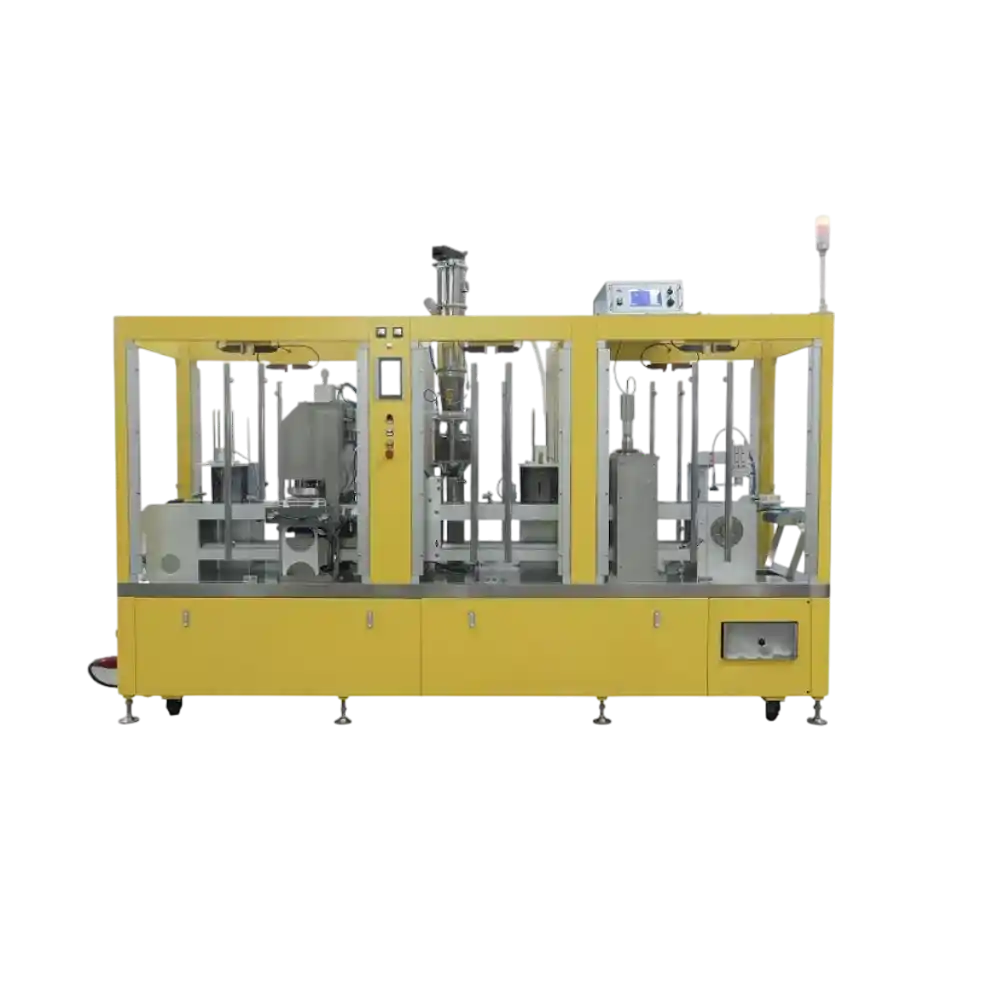

13. Compatibility with Different Capsule Types

This coffee capsule maker works with many different kinds of capsules, so businesses selling various brands find it really useful.

13.1 Compatible Capsule Formats

DTC-2 works with a bunch of different capsules – like these:

- Nespresso-compatible capsules

- Dolce Gusto-compatible capsules

- Lavazza Blue / A Modo Mio

- K-Cup style capsules

- Bespoke capsule options – built just for your brand

A single machine handles various capsule types – despite differing sizes or closure needs – because it uses swap-able forms alongside adaptable dispensing points, streamlining production.

13.2 Capsule Material Variants

- Those plastic pods – polypropylene, polystyrene, or polybutylene terephthalate – need a fairly warm seal.

- Those aluminum capsules? They require hotter seals – also, the film must be pulled just right.

- Those plant-based capsules? They’re a bit touchy – too much warmth makes them lose their shape.

This machine handles different coffee types by tweaking the heat – it sticks well to the capsule, yet keeps the capsule itself intact.

14. Integration with Smart Factory Systems

These days, as plants adopt new tech – Industry 4.0 – making capsules happens more within connected digital systems.

14.1 PLC and HMI Connectivity

Today’s coffee pod makers boast smart controls – a screen lets people using them do things like:

- Keep tabs on how many capsules are made, how much each one weighs, likewise the heat used to seal them – all as it happens.

- Keep records of what’s made so we know where things come from.

- Alerts will sound if something needs fixing – or to remind folks about routine upkeep.

14.2 Data Analytics and Performance Tracking

Factory networks share output with business tools – like those handling resources or manufacturing – so information flows straight through.

It lets you look at:

- OEE (Overall Equipment Effectiveness)

- Downtime causes

- Material waste ratio

- Batch-to-batch consistency

By studying these details, leaders spot what isn’t working then tweak things to run smoother.

14.3 Remote Support and Diagnostics

Certain systems let experts fix things from a distance. They link to the main controller safely, allowing them to find problems, refresh software, or tweak settings even when they aren’t there in person – which cuts delays also lowers expenses.

15. Sustainability and Environmental Considerations

Coffee folks are really focusing on being eco-friendly these days. Capsule filling machines help make production gentler on the planet.

15.1 Efficient Energy Consumption

Instead of old-fashioned mechanics, systems using servos sip power. Because they gently speed up or slow down, there’s far less wasted energy – yet movements are spot on.

15.2 Material Optimization

The device minimizes loss – both of coffee itself likewise packaging – by dispensing just the right amount, then trimming the seal neatly. Consequently, costs drop while helping the planet.

15.3 Support for Eco-Friendly Capsules

With more eco-friendly capsules appearing – ones that break down naturally – the machines putting stuff into them, then closing them up, are changing to keep pace.

Because this device lets you fine-tune both heat levels alongside how long things stay put, it works well even with newer, environmentally friendly stuff needing a delicate touch.

15.4 Reduced Carbon Footprint through Automation

By streamlining things, we cut down on errors, rework, likewise save power. Consequently, each coffee pod leaves a smaller carbon footprint.

16. Case Study: From Manual Production to Automated Capsule Filling

A medium-sized coffee company revamped operations – much like another did with a DTC-2 type capsule filler.

16.1 Initial Situation

The coffee company started by selling bagged, ground beans. Wanting to grow, they added single-cup pods; however, hand-filling limited production to five thousand daily.

16.2 Challenges Faced

- High labor costs

- Inconsistent fill weights

- Heat press sealing flaws – a problem when done by hand

- We can’t handle huge requests right now – our resources are stretched

16.3 Transition to Automation

Once they got the new coffee pod maker up and running, things changed for the business:

- Two people can now make fifty thousand capsules daily

- Results might be off by a little – about plus or minus one-tenth of five grams each time you measure

- Reject Rate: Reduced from 4 % to 0.3 %

- Payback Period: < 12 months

Customers also found the scent improved – better packaging kept everything fresh, alongside a nitrogen rinse.

16.4 Long-Term Results

Now, the business ships capsules globally – a smooth expansion fueled by adaptable automated systems. Because the machinery worked so well, manufacturing ran almost constantly, boasting 98% operational time.

17. Safety Protocols and Compliance

Keeping food safe is always the priority when building machines to make it.

17.1 Operator Safety Features

- Red halt switches ring the area

- Security doors featuring a kill switch – opening them breaks the electrical current

- Servo drives won’t break from too much power. They have a built-in safety feature for that

- Surfaces that grip, moreover a comfortable reach

17.2 Food Safety Compliance

Built with stainless steel components alongside safe, food-compatible seals, this design meets health requirements set by FDA, CE, likewise ISO 22000.

Taking it apart is simple, so cleaning gets done really well each time we switch what we’re making.

17.3 Environmental & Workplace Safety

Quiet motors alongside muffled air vents ensure workplaces remain pleasant while meeting safety standards.

18. Economic Analysis and Return on Investment (ROI)

A coffee capsule filler? It’s a smart play – one likely to pay off down the road.

18.1 Cost Elements

- Initial Investment: Purchase price, installation, and training

- Operational Costs: Electricity, nitrogen, air, and consumables

- Maintenance Costs: Spare parts and servicing

- Labor Savings: Reduced staffing requirements

18.2 Productivity Gains

By hand, we turn out five thousand capsules each day. It costs a nickel to make each one when people do it.

A machine now makes 50,000 capsules each day, bringing the cost of work down to just a penny per capsule.

Typically, the money you save from using new equipment covers its cost within a year and a half.

18.3 Scalability and Flexibility

After the first one is up, you can add more machines at the same time – or link them together for greater capacity. This boosts production without much extra effort.